| Model: | JZK30-75 |

|---|---|

| Brand: | Mengda |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | Shale Brick Machine , vacuum brick machine , making clay bricks |

| Price: |

US $3000

/ pc

|

| Min. Order: | 1 pc |

Product Description

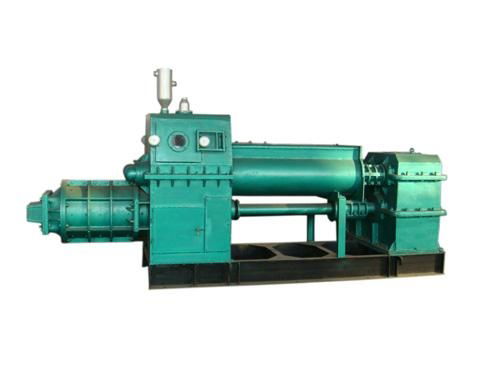

Shale vacuum brick machine is a large shale sintering red brick production equipment, it is also one of good sales machines during vacuum brick machine equipment market. After crushing, ingredients, mixing ,this equipment can extrude various gangue hollow brick .

The characteristic instructions of the shale vacuum brick machine

1. The reamer is strong and durable in use ,which choose the technique of wear-resisting material spray welding with convenient repair.

2. Its first part use Manganese alloy, which can save the cost of repair.

3. It can choose different device structure based on terrain..

4. Compact vacuum brick machine is suitable for shale, coal gangue, high content fly ash, desert soil of low plastic raw materials to produce hollow bricks.

5. Feed inlet is equipped with dual pressure clay tablets, with ZQ national standard gear reducer.

6. It is with high degree of automation, easy operation, high efficiency, and the price is very reasonable

The technical data of the shale vacuum brick machine

| specifications model |

production(pcs/h) |

motive power | dimension |

| jzk 90-4.0 | 20000 - 28000 | 132 + 315 | 9225x2890x3590 |

| jzk 75-4.0 | 16000- 24000 | 110 + 250 | 8955x3075x3310 |

| jzk 60-4.0 | 15000- 22000 | 90 + 200 | 8655x2450x2820 |

| jzk 55-4.0 | 14000 - 20000 | 75 + 180 | 8360x2800x3590 |

| jzk 50-3.5 | 13000 - 18000 | 55 + 132 | 5350x1800x2100 |

| jzk 45-3.0 | 10000 - 13000 | 110 - 132 | 4960x1680x1750 |

| jzk 40-3.0 | 8000 - 10000 | 90 - 110 | 4750x1500x1650 |

| jzk 35-2.0 | 6000 - 8000 | 55 - 75 | 3750x1340x1550 |

| jzk 30-2.0 | 4000 - 6000 | 45 - 55 | 3450x1220x1320 |

Shale vacuum brick machine maintenance and service

For a shale vacuum brick machine, the control system is the center of the whole equipment. If the control system has problems, we will be unable to realize the automation of shale vacuum brick machine production. So in the process of production, we want to keep maintenance for the shale vacuum brick machine control system.

1. If a long time not to start, please power on the PLC in the controlled cabinet once every 10 days , it needs 5 minutes per time, ( as long as closing air switch of KH1 , power on is ok).

2.Be careful not to let the wire or debris fell into the PLC, and also pay attention to waterproof.

3.This control system is adaptable to the environment, if the condition allows, please install it in the places of cement, breeze, sand, less dust.

4.Maintenance of PLC is mainly cleaning the dust powder, checking whether the connection is stable, without special maintenance.

Output 21 Million Gangue Sintered Brick Process Diagram

| Payment Terms: | TT / LC / DP / DA |

|---|---|

Member Information

| Zhengzhou Mengda Heavy Machinery Factory | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 07548673 |

| Contact: | fanny (manager) |

| Last Online: | 10 Mar, 2015 |

Related Products of this Company

-

Hot Selling Compact Vacuum Brick

US $3000

-

Professional gangau Vacuum Brick Machine

US $3500

-

Henan Full-Automatic Vacuum Brick

US $3000

-

Made in China Compact Vacuum Brick

US $3000

-

High Efficiency clay vacuum Brick

US $3000

-

Hot Selling Gangue Vacuum Brick Machine

US $3000

-

New Style High Output Double shaft

US $1000

-

New Type High Output Brick Cutter

US $500

-

New Style Clay Vacuum Brick Machine

US $3000

-

New Style Fly Ash Vacuum Brick Making

US $3000