Conical twin-screw features:

WPC material handling device consists of deep grooves, big pitch, big volume, uncompressed bimetallic alloy screw and barrel structure consisting of; increase the cylinder exhaust port, in any combination, widely adaptable according to the material process requirements

Wood pelleting die:

Die made of high quality steel mold and bake plated handle, reasonable distribution of stream crossings, to ensure uniform particles affect each other out, with the precision cutter ensures smooth section, frequency control is more adapted to the different granulation needs.

Cooling system:

Unique three-dimensional cooling type structure, combining multiple powerful new cooling fan, the cooling effect is more. With high efficiency, low energy consumption, especially for wood pelletizing process.

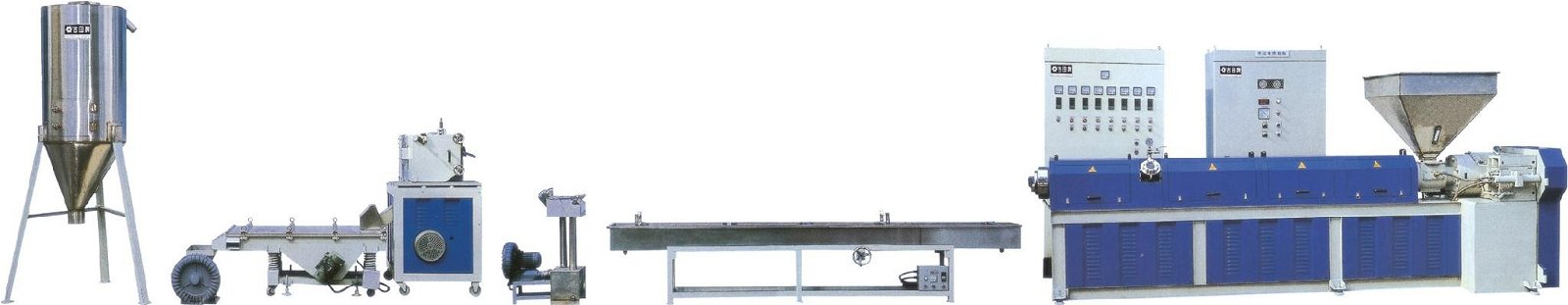

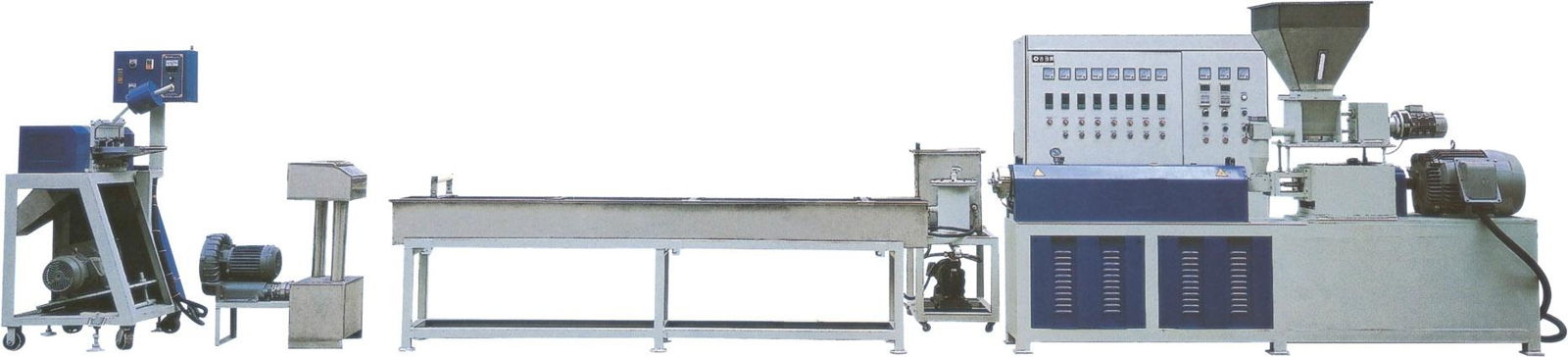

PP, PE wood-plastic production process: raw materials + flour + additives - mixing - granulating - conical twin screw extruder - Extrusion mold - mold cooling - vacuum given by the chamber - Cutters - stacking frame - finished product testing packaging

PVC wood-plastic production process: raw materials + flour + additives - mixing - granulating - conical twin screw extruder - Extrusion mold - mold cooling - vacuum given by the chamber - Crawlers Machine - Cutting Machine - stacking frame - finished product testing packaging