| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | BEER BREWING , beer brewery , brewery equipment |

| Price: |

US $35000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Company basic information

1.name:DEGONG Equipment Technology Co.,Ltd.

2.nature:exporter&manufacture

3.industrial field:beer brewing equipment

4.origin:Jinan,Shandong province,China

5.established time:2012

6.capacity:50-10000L beer brewing equipment

7.output:100/D,200/D,300/D....1000/D,2000/D....10000/D

8.target:Asia,Europe,Afric,The America,Austrilia..ect

The fundamental information of the beer brewing equipment

1)We can not only produce 100L,200L mini beer brewing equipment,but also produce 1000L,

2000L,3000L,5000L commercial used beer brewing equipment.

2)The outsourcing material can be stainless steel or red copper.

3) High quality raw material and accessories,double wall tanks.Both sides with good quality

stainless steel and well polished.

4)Customized beer brewing equipment,you can tell me your specific requirements,and

we will design the equipment according to your needs

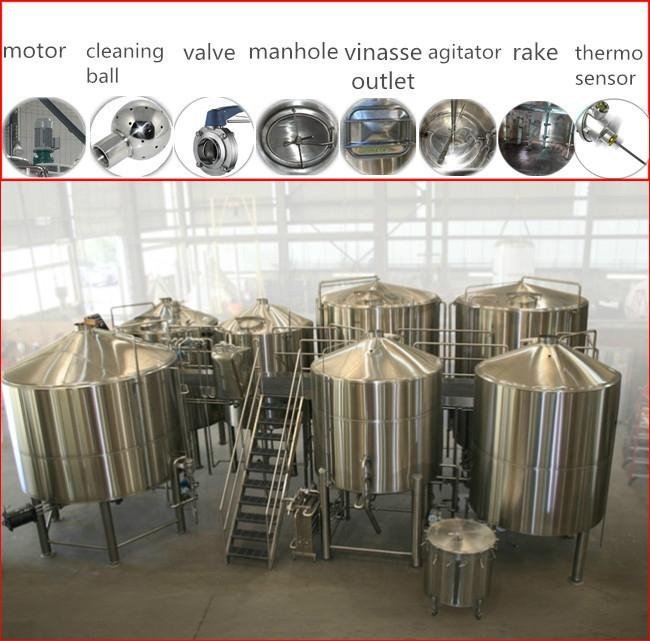

There are six system for the '' Conical 5bbl beer brewing/brewery equipment made in china | DEGONG '':mill system,mashing system,fermentation system,cooling system,control system and cleaning system

1.mill and mashing system

|

mash system

|

Mash/lauter tank Boiling/whirlpool tank Hot water tank |

3-vessel mash system steam heating method red copper or stainless steel |

|

Plate heat exchanger |

Design pressure:1.0Mpa , work temperature:170° |

|

|

Wort pump |

Capacity:3000L/h ,Rev:2880r/min |

|

|

Steam boiler |

electric steam boiler, gas fired steam boiler,oil fired steam boiler |

|

|

Wort measuring meter |

measurement temperature gauge |

|

|

Measuring cylinder |

SUS 304 |

|

|

Mill machine |

200kg/h |

|

|

Venturi tubes |

DN 25,Caliber:φ32 |

|

|

pipelines&valves |

Food grade SUS 304 pipeline |

the technical parameter of mash/lauter and boiling/whirlpool tank:

a.stainless steel or red copper

b.inner surface thickness:3.0mm,weld grinded to Ra 0.6 μm

c.outer surface thickness:3.0mm,weld grind polishing process

d.jacket thickness:3.0mm,jacket pressure:0.3mpa

e.insulation:polyurethane,thickness:100mm

f.temperature way:double metal thermometer

g.cleaning method:360 degree omni bearing cleaning

h.electric heating,steam heating,direct fire heating

2.fermentation system

|

fermentation system |

Fermentation tank |

60 degree conical bottom to drip yeast |

|

Beer bright tank |

150 degree conical bottom |

|

|

Yeast adding tank |

50L,Stainless steel |

|

|

Pipelines&valve |

Food grade SUS 304 pipelines |

|

|

Food tube |

Includes tube joints and hose hoops |

|

|

Refrigerant pipelines |

Includes valves&pipeline |

the technical parameter of fermentation tank and beer bright tank:

a.material Inner SUS304

b. Inner thickness: 3.0mm; Outer thickness:2.0mm;External-Jacket thickness: 1.5mm;

c.Surface: Finish2B – cold-rolled, annealed, pickled

d.Inner surface treatment: welds grinded to Ra 0.6μm (attached 360 degree Omni cleaning ball

e.Mirror surface finish inside.

f.Insulation: Polyurethane-thickness100mm.

g.Equipment with : cone 60°(fermentation tank)resist compression design

h.Cleaning System: All-round cleaning

i.Control Method: temperature control,voltage-controlled and hand automatic control

j.Vessel Pressure:1.5 bar / 3.0 bar

3.cooling system

|

cooling system |

ice water tank |

stainless steel thickness:3.0mm insulation:polyurethane,thickness:100mm |

|

refrigerating unit |

Medium:Freon R-404A Working voltage:380V Power:8.25KW |

|

|

circulate pump |

Flow:3 m3/h, Lift:25m, Power:0.75KW |

|

|

refrigerating pipeline |

Food grade SUS 304 |

4.Cleaning system

|

cleaning system |

sterilization tank |

stianless steel,2.0mm

inner surface:weld grinded to Ra 0.6 μm |

|

alkali tank |

||

|

washing pump |

SS anticorrosion pump, lift:18m Rev:2880r/min |

5.Control system

|

control system

|

Mashing control |

Manual operate

Instrument

Semi-Auto-control

1 set

|

|

Fermenting control |

||

|

Cooling control |

||

|

Cleaning control |

||

|

Hot water Tank |

||

|

Ice water tank |

mash system

fermentation tank

cooling system

CIP cleaning system

control system

Service

1. Providing beer production technology, brewing formula and person training service.

2. Providing cost analysis, brew house design, equipment production.

3. Implementation of turnkey projects, equipment, 18 months free warranty and provide

technical services for many years.

4. Provide other with beer production-related items such as beer kegs, liquor valves, etc.

Trade information

1.usually adopt FOB trade term

2.30% - advance payment after signing the contract

70% - after the preparation of equipment for shipment / 3 days before shipment;

3.T/T payment

Our factory

Member Information

| DEGONG Equipment Technology Co.,Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 58780868 |

| Contact: | fern (saleswoman) |

| Last Online: | 27 Oct, 2015 |

Related Products of this Company

-

1000L beer brewhouse beer brewery

-

7BBL beer brewing equipment

US $55000

-

100L electric heating micro beer brewing

US $15000

-

1500L stainless steel micro brewery

US $65000

-

500L restaurant/hotel brewery equipment

US $35000

-

micro commercial beer brewery equipment

-

1000L turnkey beer brewing equipment

-

500L micro brewery equipment made in

US $45000

-

7bbl beer brewey equipment microbrewery

-

Beer brewing kettle for 500l

US $35000