| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | MICRO BREWERY , commercial brewery , micro beer equipment |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Degong Equipment Technology Co.,Ltd Jinan

Degong has been in this line of beer brewing equipment for a few years, just begin the international trade in 2012. In 2008, we mainly do China, ourselves market here. Latter, because domestic market was bigger and bigger, many Chinese customers who introduced their foreign customers and friends to us. so gradually, we accumulated many foreign customers and they come to us, visit our factory and check our equipment, at last,for now, we not only have domestic market of beer brewery equipment but also we do many foreign customers' requirement.

(50L/D,100L/D, 200L/D, 300L/D, 500L/D, 1000L/D, 2000L/D, 3000L/D,5000l/D)

Of course, we also very hope we can work together to provide the most wanted equipment and most suitable scheme to you.

Service range

we can provide the below types equipment:

1)Hotel Micro brewing factory;

2)Pub Mini Beer Brewery equipment;

3)Home mini beer brewery equipment;

4)Restaurant & Barbecue beer brewing system;

5)Large beer brewing factory;

6)One whole set of brewing equipment;

7)parts of equipment;

(just like fermenters, beer bright tanks, storing tanks, mashing system tanks etc...)

Purchase service

1. Main tanks, vessels and machines will be packaged/welded with steel frames.

2. All spare parts, accessories and fittings will be packaged with wooden case.

3. All items wrapped with soft package for protection.

4. Standard shipping containers will be used for general purpose.

5. All equipments will be loaded into containers according to exact container layout drawings.

6. After loaded into containers, all equipments will be well fixed to the containers.

Product Description

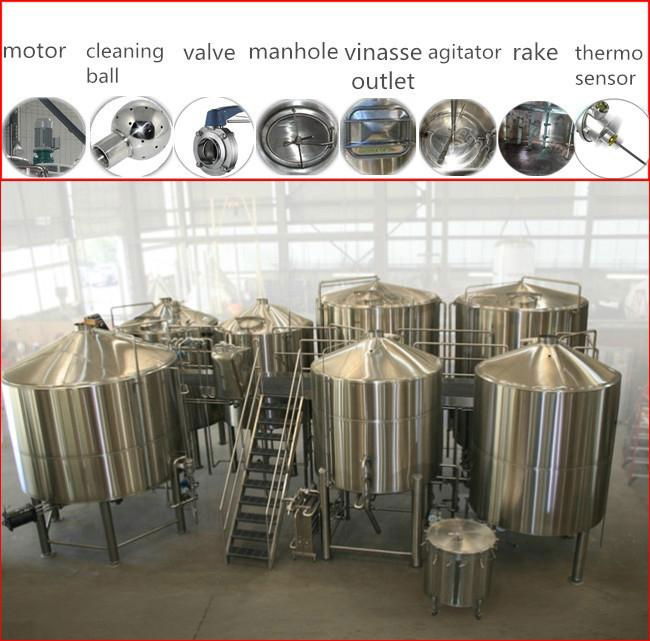

Whole set of micro/commercial beer brewery equipment has Malt Mill system, Fermenting

system, Cooling system, CIP cleaning system and Semi-automatic/ PLC control system,

necessary accessories.

Mashing system configuration:

Heating is done with steam that heats the side and bottom of the cooking. Steam heating systems

are a lot better than direct heating through gas or thermal oil as they are more powerful, very responsive,

and prevent the mash from caramelizing and sticking to the bottom of the vessel. Furthermore a steam

operated brew house gives a better "rolling boil" and a better acidity extraction from your hops.

Fermenting system configuration:

Jacketed Conical Fermentation Tanks are available from 1 Barrel to 100 Barrels.The conical

fermentation tanks have a dish top with cylindrical body. The 60 Degree conical bottom is

ideal for fermenting and improving the quality of beer as well as breeding yeast. All tanks are

food grade stainless steel 304 with a 3 mm thickness for 3BBL-70BBL, while larger tanks have

a 4 mm thickness. The cooling system is a dimple jacket with insulated polyurathane filling.All

tanks are designed for up to 20 PSI and tested at 45 PSI. (1.5BAR/3.0BAR) The inside of the

tanks are polished to Ra>0.4um and the outside is a Brushe/Satin finish.

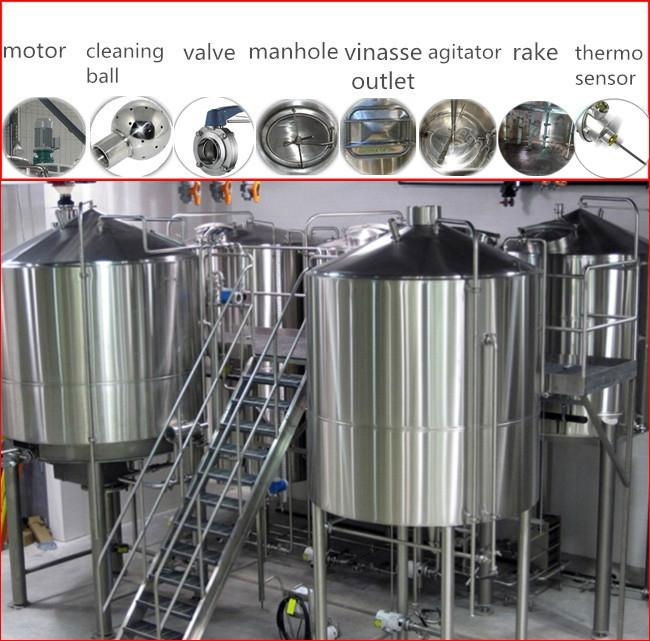

Customized parts :

A) Cone Degree: 60-90degree

B) Manway door can be on dish head or cylinder

C) Can be one section or two section cooling jacket ;

D) The height can be adjustable according to the building ceiling ;

E) Dry hops adding hole on dish head ;

F) Racking arm on the cone;

Whole set of beer brewery equipment with high quality material:

Certifications

Packing and loading into container

Wooden case or as the customers' requirement.

Packed by bubble film for all tanks;

Outside with iron welding and fixed.

If you are interested in our equipment,please contact me

fern@degonget.com

Member Information

| DEGONG Equipment Technology Co.,Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 58780868 |

| Contact: | fern (saleswoman) |

| Last Online: | 27 Oct, 2015 |

Related Products of this Company

-

1500L stainless steel micro brewery

US $65000

-

500L micro brewery equipment made in

US $45000

-

Crafr 1000L beer making machine

-

1000L stainless steel commercial beer

-

500L beer brewing equipment beer brewery

US $40000

-

1500L beer brewing equipment from china

US $68000

-

7BBL beer brewing equipment

US $55000

-

Beer mashing system 400L for sale

-

1000L high quality large beer

US $58000

-

100L electric heating micro beer brewing

US $15000