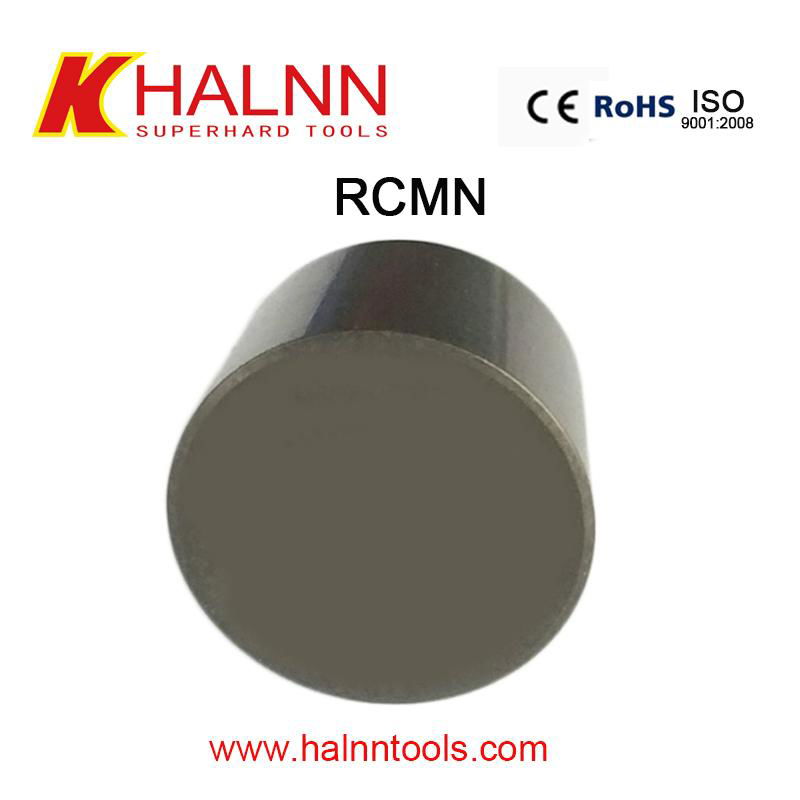

| Model: | Solid CBNinsert |

|---|---|

| Brand: | Halnn superhard material Co.Ltd |

| Origin: | Made In China |

| Category: | Industrial Supplies / Tools / Abrasives |

| Label: | Hard machining , Halnn Pcbn inserts , PCBN inserts |

| Price: |

US $25

/ pc

|

| Min. Order: | 10 pc |

Product Description

Hard Machining bearing ring PCBN inserts from Halnn superhard Materials

First ,we need know something about Hard turning bearing ring

technology,Halnn superhard Materials Co.Ltd will show you as follows:

a.Finish turning the base level end,the base level end will be less than

0.005 mm after finish turning,then turning the outer diameter of the shaft

washer;

b.Turn to another face for turning

c.Step 1: Turning the upper end surface (inside the channel);

Step 2:convert the work piece platen, then turning the upper end surface.

(outside the channel)

d.Hard turning the spherical channel(Halnn superhard CBN spherical inserts

),the channel bottom range will less than 0.005 mm after hard turning ,the

channel surface roughness will be Ra 0.3μm

e.Finish turning inner diameter of the shaft washer.

With above technology ,the wall thickness difference of the push ball

bearing ring will less than 0.01 mm,which is more than the precision value

of P5 grade bearing .

The following is application Case:Hard turning the wind power bearing ring

Machining Targets: variable pitch bearing ring used for 1.5 MW wind power

machine sets.

Machine: CNC Vertical Lathe

Cutting Inserts Grade: Halnn superhard BN-S20

Work piece Dimension: Outer diameter φ1900 mm,Thickness 130 mm,

Roughness after finish turning:The channel bottom range of double peach

channel after finish turning all less than 0.005 mm ,and the channel surface

roughness will reach Ra 0.3μm.

Advantages of hard turning the bearing ring

1.High working efficiency

For example,like variable pitch bearing ring which is used for machining

wind power 1.5 MW machining sets in bearing industry.If grinding machining

all the allowance after quenching ,the grinding time is above 18 h, but use

the turning instead of grinding process,just need 4.5 h.At the same

machining precision ,the turning machining efficiency is 4 times than

grinding machining .

2.Low cost

For example , like turning the 1900 variable pitch bearing ring ,use Halnn

superhard BN-S20 grade solid CBN inserts can finish turning more than 30

piece bearing ring.

3.Reduce pollution

Compared with the grinding iron grain with the turning iron scraps,it will

be more convenient to deal with the iron scraps,and the irons scraps cost

lower as resource,also reduce the pollution.

Halnn superhard Materials Co.,Ltd is a professional manufacturer of CBN

Cutting Tools,and we are always devoted to researching new type cbn inserts

to satisfy the customers requirements. Halnn will serve the best service and

good quality products .

Related Video,https://www.youtube.com/watch?v=3uLOVm-wlIs.Any question ,you can contact with us halnntools@gmail.com

.skype:cbn_inserts_angels

Member Information

| Halnn superhard material Co.,Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18695866134 |

| Contact: | Angels Zhu (sales manager) |

| Last Online: | 07 Jul, 2017 |

Related Products of this Company

-

Hard turning hardened steel parts used

US $25

-

Rough turning High chromium cast iron

US $25

-

CNMN BN-S20 Hard turning insert form

US $25

-

Rough machining forged steel cold rolls

US $30

-

Halnn BN-K1 grade CBN inserts for

US $25

-

SNMN BN-S20 CBN inserts to hard turning

US $25

-

China Mainland Halnn Cutting Tools

US $25

-

RNMN BN-S30 Solid CBN inserts to

US $30

-

CBN inserts hard turning quenched steel

US $25

-

Hard Machining bearing steel after

US $25