| Model: | HalnnCBNinserts |

|---|---|

| Brand: | Halnn superhard material Co.Ltd |

| Origin: | Made In China |

| Category: | Industrial Supplies / Tools / Abrasives |

| Label: | Hard Turning , CBN inserts manufact , Halnn |

| Price: |

US $25

/ pc

|

| Min. Order: | 10 pc |

Product Description

Hard Turning Bearing Steel after quenching CBN inserts from Halnn superhard Materials

Specific to hard turning hardened bearing steel after quenching ,Halnn researched special cbn inserts grade to satisfy customers requirements.And the following Halnn will show you the cutting parameters choices.

Part 1 The hardness of bearing steel after quenching

The hardness of bearing steel after quenching usually is above HRC45,some even more than HRC60.Common hardness comparison table which people usually used is not suit for quenched steel.

Part 2 When need CBN inserts hard turning bearing steel after quenching

Firstly,we need choose the most suitable inserts material to hard turning bearing steel after quenching.

We can choose CBN inserts if the hardness of the bearing steel after quenching is above HRC55.

We can choose ceramic inserts to machining bearing steel after quenching if the hardness is below HRC45 and finishing process comparing the economy

If just hard turning quenched steel un-frequent,we can consider YT726 or others carbide cutting tools.

Notice:PCBN inserts(Halnn superhard researched BN-H10,BN-H20 grade)cutting depth usually is within 0.3mm,and it need try to avoid interrupted turning,it can get a good surface roughness when finish turning bearing steel,realize turning instead of grinding.If the cutting depth is above 0.3mm or interrupted turning quenched steel,BN-S20 grade from Halnn superhard material company can meet this requirement completely.(BN-S20 grade CBN inserts cutting depth can reach above 7mm when hard turning quenched steel)

Part 3 The Cutting parameters of CBN inserts hard turning bearing steel after quenching

CBN inserts hard turning quenched bearing steel:

Cutting speed:80-120m/min

Finishing allowance:about 0.3mm

Feed Rate:about 0.1mm/r

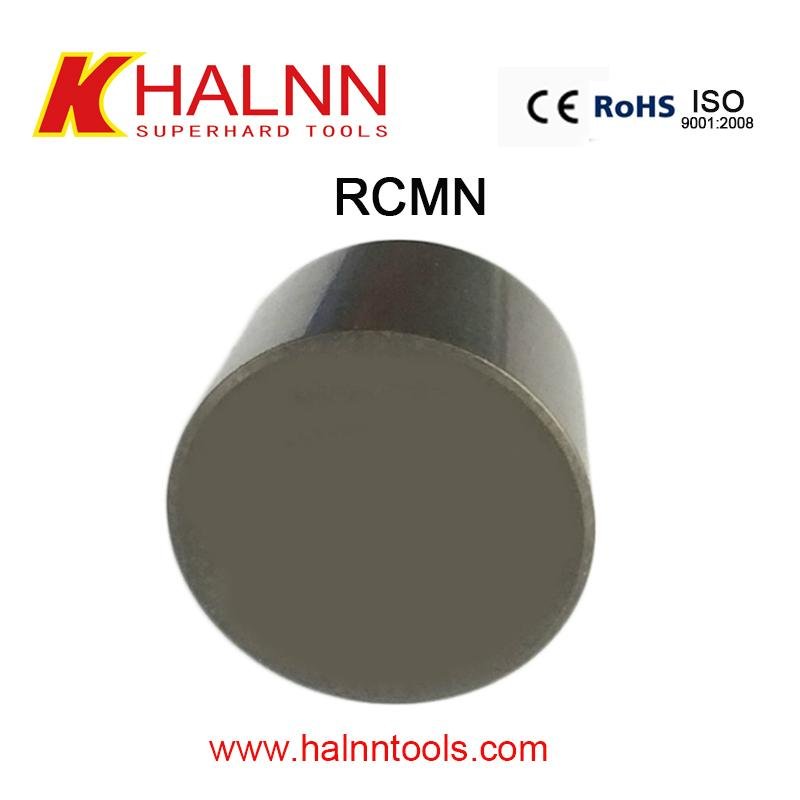

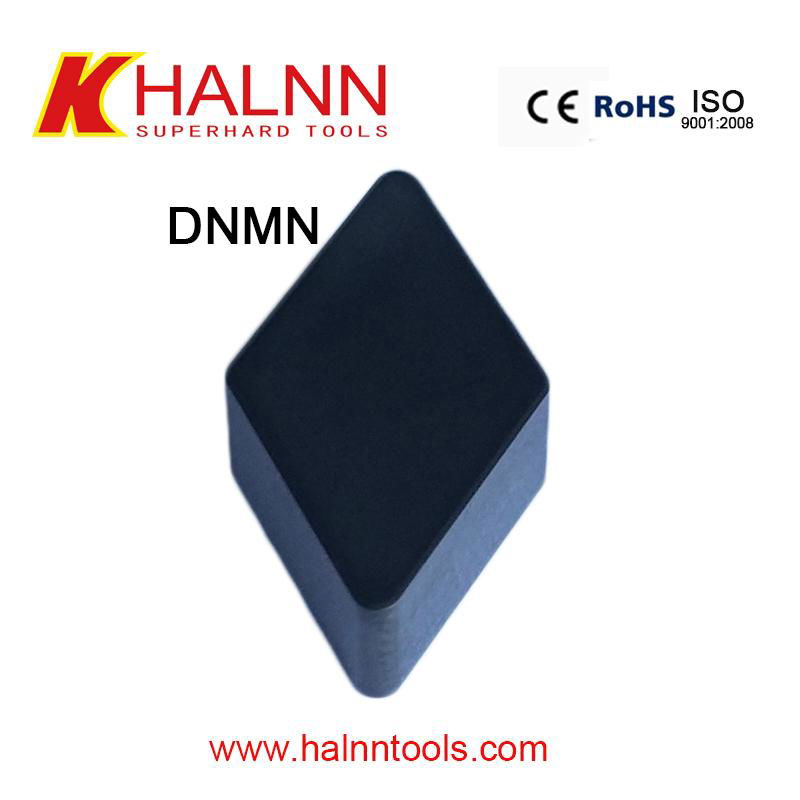

Part 4 CBN inserts parameter Selection

CBN inserts parameters:usually chose 0.2*20 degree chamfer when roughing or interrupted machining,choose 0.1mm width chamfer when finishing,the tools nose radius of circular arc according to the detail condition.

Part 5 Notes when using CBN insert hard turning quenched bearing steel

(1)Dry cutting,if there are some reason so that need add fluid,you can use Halnn company BN-H10 grade CBN inserts,this grade insert has a good lifetime under wet cutting.

1.Choose the CBN inserts grade:

we should chose BN-H20 when turning the bearing steel instead of grinding,try to shorten the extended length of holder for decrease the vibration and get a better surface roughness.

We recommend BN-S20 grade CBN insert,If the machining allowanceis a little big,.(This two grade CBN insert are both researched by Halnn superhard material Co.,Ltd.)

And we have so many video on som application case,https://www.youtube.com/watch?v=3uLOVm-wlIs

More details,http://www.halnntools.com/pro ,Or contact with us halnntools@gmail.com,skype:cbn_inserts_angels

Member Information

| Halnn superhard material Co.,Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18695866134 |

| Contact: | Angels Zhu (sales manager) |

| Last Online: | 07 Jul, 2017 |

Related Products of this Company

-

China Mainland Halnn superhard Cutting

US $25

-

Hard turning hardened steel parts used

US $25

-

Halnn BN-S20 grade CBN inserts for hard

US $25

-

Rough Turning steel iron roll used CBN

US $35

-

Hard Machining bearing ring Pcbn inserts

US $25

-

RNMN BN-S30 Solid CBN inserts to

US $30

-

Hard Cutting Tools hard turning hardened

US $25

-

Halnn BN-K1 grade CBN inserts for

US $25

-

Hard turning slewing bearing instead of

US $25

-

Rough turning High chromium cast iron

US $25