Low corrugated fin pipe is mainly used in strengthening the lateral gas full or partial condensation process.

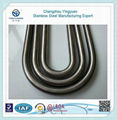

Corrugated low finned tube after no cutting of the rolling process, the light tube cold rolled into the surface with low finned and spiral drainage trough, tube forming processes of spiral double reinforcement of condensation heat transfer within the new pipe type bF tube (patent number: ZL20090193164.5).

Finned tube outer low expansion condensation surface area nearly 1.6 2 times, spiral drainage trough can destroy fin grooves condensate rely on surface tension, the function of stranded will condensate along the spiral groove guide to the bottom of the tube, then ruled out by gravitational force.This kind of tube type enlarged the condensing surface, and reduce fluid retention in low finned tube groove, the influence of the condensate film thinning to greatly strengthen the condensation heat transfer.Because of the formation processes of tube inner spiral corrugated pipe, corrugated pipe to strengthen tube without phase change heat transfer process.At the same time, also can destroy the wall of tube ripple stranded layer, prevent or reduce the scale of sedimentary, antiscale effect.

So is to realize the double strengthening bF tube condensing heat transfer process of new type pipe.Due to the rolling process achieve a molding, greatly reduce the processing cost, conducive to industrial popularization and application.