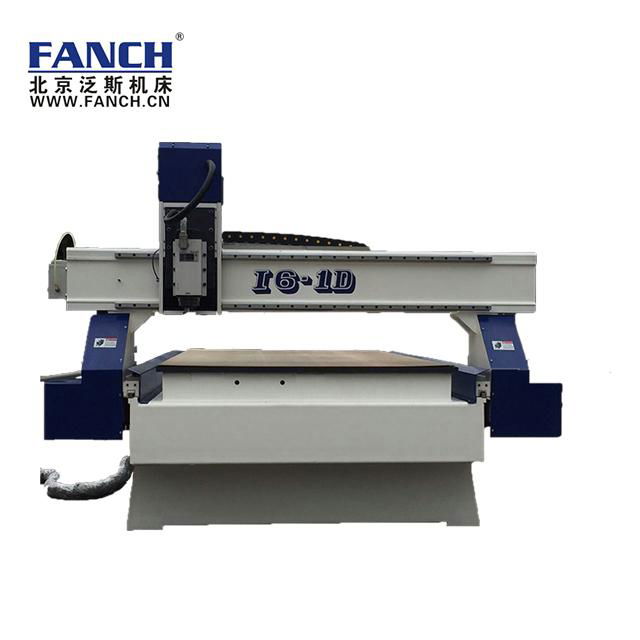

| Model: | FC-I6-1D |

|---|---|

| Brand: | FANCH |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | Wood CNC Machine , CNC Cutting Machine , CNC Router |

| Price: |

US $7000

/ Set

|

| Min. Order: | 1 Set |

Product Description

4' X 8' Single spindle cnc wood mills basic cnc router

Model: FC-I6-1D (1300*2500mm, China 6.0KW manual tool changing spindle)

Product Description

Woodworking cnc router machine

One head CNC router

Single spindle cnc router machine

Application&Samples

Materials:

Acrylics: acrylics, backlight module faceplate, liquid crystal diffuser plate, etc.

Thermoplastic elastomers: rubber, plastic, resin, foam products, etc.

Engineer plastics: PVC, ABS, PF, PE, PU etc.

Compound materials: FRP, artificial stone, compact board, graphite, laminates, etc.

Wood material: solid wood, wood based panel, MDF, triplay etc.

Light metal material: aluminum extruded, copper, aluminium profile.

Industries:

1. Furniture industry

All kinds of board type furniture, wooden doors, cabinets, solid wood furniture cutting and engraving,

2. Advertising industry

Craft gifts, crystal ornaments, advertisement sign, mini word engraving cutting, etc;

3. Decoration Industry

Acrylic, PVC, density board, plastic, aluminum and copper, etc of soft sheet metal ornamental milling cutting processing

4. Plate processing

Insulation, plastic chemical parts; PCB, High-speed train body panel, bowling track; Compact plate, epoxy resin, ABS, PP, PE and other carbide mixture

Specification

|

Parameters: |

|

|

X Y axis travel |

1300*2500mm |

|

Z axis travel |

>200mm |

|

Table size |

1340*2500mm |

|

Resolution |

±0.001mm |

|

Max running speed |

25m/min |

|

Max feeding height |

200mm |

|

Spindle power |

China 6.0KW air-cooling |

|

Spindle speed |

6000-18000rpm/min |

|

Control system |

NC Studio |

|

Software operating environment |

Windows98/2000/XP |

|

Command language |

G code.uoo.mmg.plt |

|

Work voltage |

AC380V/50Hz |

|

Work mode |

Stepper |

Features

Machine Bed: High-quality steel structure welding seamless

Machine Parts: Aluminum casting

Spindle: China 6.0KW air-cooling spindle

Driver: Shenzhen LEADSHINE hybrid servo

Motor: Stepper

Transmission: Imported synchronous belt-pulley transmission

Control System: Shanghai NC Studio

Inverter: Shenzhen INOVANCE

Linear Guide Rail: Taiwan HIWIN 30mm (X/Y axis) and 25mm (Z axis)

Rack and Pinion: Taiwan XINYUE (X/Y axis)

Ball Screw: Taiwan TBI (Z axis)

Working Table: Vacuum adsorption

Electrical Components: French Schneider, Taiwan AirTAC

Spare Parts

|

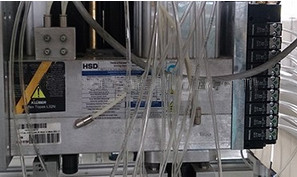

Spindle Name: Main Spindle Brand: HSD Original: Italy Original Italy imported spindle 6.0KW, it promise more accurate, higher working efficiency. We can increase and reduce spindle numbers according to customer's need. |

|

Motor Name: Spindle motor

|

|

Servo Name: motor servo

|

|

Helical rack Name: Helical rack

|

|

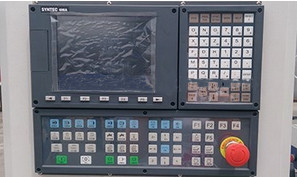

Control system Name: SYNTEC Control system

NC studio system is optional. |

|

Inverter Name: Delta inverter Brand: Delta Original: Taiwan Top brand inverter ensure the stability of working process. SUNFAR inverter is optional. |

|

Linear rail Name: Linear rail Brand: HIWIN/PMI Original: Taiwan Automatic lubrication rail, free maintenance. |

|

Reducer Name: Planetary reducer Brand: Neugart Original: Germany Good quality reducer can help to improve the repeat position accuracy. Japanese Shimpo and Taiwan APEX are optional. |

|

Electric components Name: Electric components Brand: Schneider Original: French Taiwan AirTAC is optional. |

Factory

Woodworking Machine

Located in Tongzhou district, Beijing, Fanch woodworking factory was established in 2006. There are about 100 worker and technicians working in welding, milling and assembly departments.

|

|

|

|

|

Laser cutting machine factory

Located in National Innovation Industry Park in Tongzhou, Fanch laser machine assembly department, R&D office and

domestic sales office can be found here.

|

|

|

|

Our Services

|

|

||

|

Pre-sale service 1. Free engineer consultant and feedback in 24 hours. 2. Sample specimens and testing video of specified machine are available. 3. Factory visit arrangement.

|

After-sale service 1. Prompt reply in 24 hours. 2. Engineer on-site installation. 3. Call-in Remote diagnosis. 4. Engineer oversea service. 5. Operation training service.

|

Customized service 1. OEM/ODM service are available. 2. Free engineer consultant 3. Engineer on-site installation and deb ing. 4. Operation training service

|

Contact Us

Beijing FANCH Machinery Co., Ltd

Beijing FANCH Machinery Co., Ltd

Contact: Mr. Tonboy

Mob/Whats App/WeChat: +86 15810807690

Skype: leirezhang2

Email: fanch005[at]fanchcnc.com

Web:www.fanchcnc.com

Member Information

| Beijing Fanch CNC Machinery Co.,Ltd | |

|---|---|

| Country/Region: | Beijing - China |

| Business Nature: | Manufacturer |

| Phone: | 15810807690 |

| Contact: | Tonboy (Salesman) |

| Last Online: | 20 Dec, 2019 |

Related Products of this Company

-

Special design ! ATC CNC router / PTP

US $37000

-

Discount price ! 5-axis machining

US $114200

-

Hot sale customized kitchen cabinet and

US $31600

-

Acrylic luminous characters/high light

US $14500

-

CNC stone cutting and polishing machine

US $56000