| Model: | SKD-3015ATC |

|---|---|

| Brand: | SKD |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | Countertop Machine , Stone CNC Carving , CNC Machining Center |

| Price: |

US $56000

/ Set

|

| Min. Order: | 1 Set |

Product Description

CNC stone cutting and polishing machine for quartz, granite, marble

Model: SKD-3015ATC Italy 11.0KW water cooling ATC spindle

Product Description

ATC stone CNC engraving machine for grave renovation

Headstone carving machine

CNC granite carving machine

Application&Samples

Application

SKD-3015ATC is the stonecarving brand of FANCH GROUP. It is the ATC type cnc stone router machining center for profiling special-shaped edges,high-end table,washbasin,cabinet and stone carving works,with high strength,high precision and high efficiency.

Following industry are available

1. Countertop Manufacturing

2. Detailed Decorative Designs

3. Monuments & Memorials

4. Kitchens & Baths

5. Tiles

6. Modular Panels

7. Signs

Specification

|

Working area |

3000*1500mm |

|

Processing accuracy |

0.05m |

|

Repeat position accuracy |

0.05mm |

|

Tool magazine |

18 pieces |

|

Spindle speed |

2000-12000rpm/min |

|

Engraving commend |

Code G.uoo.mmg.plt |

|

Software operation environment |

Windows98/2000/XP |

|

Working voltage |

AC380V/50HZ |

|

Spindle power |

11.0KW water-cooling ATC |

|

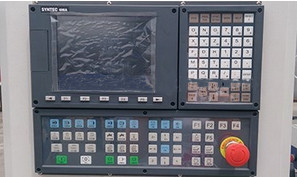

Control system |

Taiwan SYNTEC |

|

Tool diameter |

Φ3.175 Φ4 Φ6 Φ12.7 |

|

Working mode |

Japan YASKAWA servo |

|

Dimension |

5400*3600*2500mm |

|

Weight |

5600KGS |

Features

|

Lathe Bed: Industrial design plate welding, 600 degree high temperature quenching processing Machine Parts: Industrial aluminum casting structure Working Table: Full aluminum Drive Motor/System: Japan YASKAWA large power bus servo Spindle: Italy EMA 11.0KW air-cooling ATC spindle, 2000-12000rpm Tool Magazine: 18 straight line tools, ISO 40 tool holder Inverter: Taiwan Delta Control System: Taiwan SYNTEC EM20 Linear Guide Rail: Taiwan HIWIN/PMI 30mm Gear and Rack: Taiwan high precision Ball Screw: Taiwan TBI Electrical Components: French Schneider, Taiwan AirTAC Double station and multiple suckers processing design Standard equipped with three axis safety protection device and centralized lubrication system for transmission parts |

Spare Parts

|

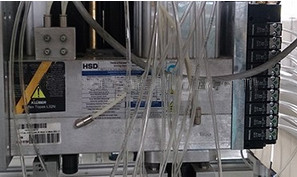

Spindle Name: Main Spindle Brand: HSD Original: Italy Original Italy imported spindle 6.0KW, it promise more accurate, higher working efficiency. We can increase and reduce spindle numbers according to customer's need. |

|

Motor Name: Spindle motor

|

|

Servo Name: motor servo

|

|

Helical rack Name: Helical rack

|

|

Control system Name: SYNTEC Control system

NC studio system is optional. |

|

Inverter Name: Delta inverter Brand: Delta Original: Taiwan Top brand inverter ensure the stability of working process. SUNFAR inverter is optional. |

|

Linear rail Name: Linear rail Brand: HIWIN/PMI Original: Taiwan Automatic lubrication rail, free maintenance. |

|

Reducer Name: Planetary reducer Brand: Neugart Original: Germany Good quality reducer can help to improve the repeat position accuracy. Japanese Shimpo and Taiwan APEX are optional. |

|

Electric components Name: Electric components Brand: Schneider Original: French Taiwan AirTAC is optional. |

Factory

Woodworking Machine

Located in Tongzhou district, Beijing, Fanch woodworking factory was established in 2006. There are about 100 worker and technicians working in welding, milling and assembly departments.

|

|

|

|

|

Laser cutting machine factory

Located in National Innovation Industry Park in Tongzhou, Fanch laser machine assembly department, R&D office and

domestic sales office can be found here.

|

|

|

|

Our Services

|

|

||

|

Pre-sale service 1. Free engineer consultant and feedback in 24 hours. 2. Sample specimens and testing video of specified machine are available. 3. Factory visit arrangement.

|

After-sale service 1. Prompt reply in 24 hours. 2. Engineer on-site installation. 3. Call-in Remote diagnosis. 4. Engineer oversea service. 5. Operation training service.

|

Customized service 1. OEM/ODM service are available. 2. Free engineer consultant 3. Engineer on-site installation and deb ing. 4. Operation training service

|

Contact Us

Beijing FANCH Machinery Co., Ltd

Beijing FANCH Machinery Co., Ltd

Contact: Mr. Tonboy

Mob/Whats App/WeChat: +86 15810807690

Skype: leirezhang2

Email: fanch005[at]fanchcnc.com

Web:www.fanchcnc.com

Member Information

| Beijing Fanch CNC Machinery Co.,Ltd | |

|---|---|

| Country/Region: | Beijing - China |

| Business Nature: | Manufacturer |

| Phone: | 15810807690 |

| Contact: | Tonboy (Salesman) |

| Last Online: | 20 Dec, 2019 |

Related Products of this Company

-

Discount price ! 5-axis machining

US $114200

-

Acrylic luminous characters/high light

US $14500

-

4' X 8' Single spindle cnc wood mills

US $7000

-

Hot sale customized kitchen cabinet and

US $31600

-

Special design ! ATC CNC router / PTP

US $37000