| Model: | WH-VI-200 |

|---|---|

| Brand: | LIPAI |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Heater |

| Label: | induction heating , heating machine , hardening machine |

| Price: |

US $13000

/ set

|

| Min. Order: | 1 set |

Product Description

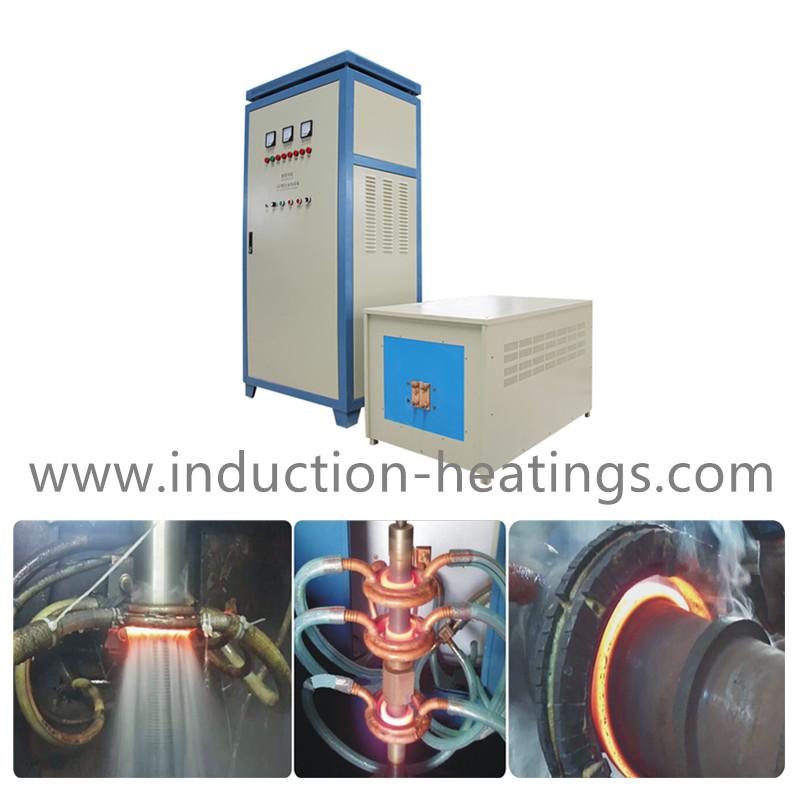

Supersonic frequency IGBT induction heating quenching equipment

Features of induction quenching equipment:

1.Heating: this is the heating rate of less than 1 second (speed adjustable speed control)

2.Heating wide: wide range of metal parts can be heated (according to the different shape of the workpiece replacement of removable induction loop)

3.Easy installation: connect the power, induction loop and out of the water can be used; small size, light weight, easy to use

4.Simple: a few minutes to learn

5.Start fast: you can start with water after the heating power

6.Low power consumption: high-frequency device than the old-fashioned tube about 70% energy saving, the smaller the power consumption of the smaller parts

7.Good effect: the heating is very uniform (also by regulating the induction coil density, so that all parts of the workpiece to obtain their desired temperature), heating up fast, less oxide layer after annealing without waste

8.Adjustable Power: The Promise adjust the output power

9.Protection of all: with over voltage, over current, overheating, lack of water and other alarm indicator, and automatic control and protection

Technical parameter of induction quenching equipment:

model |

WH-VI-200 |

Worker power |

Three phrase 380V/50Hz |

Working voltage range (AC) |

350V~410V |

Max output power |

200KVA |

Oscillation frequency |

10-35KHz |

Continuous load rate |

100% |

Cooling water pressure |

0.2-0.3mpa |

Host weight |

93kg±5% |

Transformer weight |

120kg±5% |

Host dimensions(L*W*H)mm |

650*520*1100 |

Transformer dimensions (L*W*H)mm |

500*800*580 |

Temperature protection |

50 degrees |

| Our induction heating machine will be devided into Four parts to introduced | |

| One | Advantages of our induction heating machine |

| Two | Capacity of our induction heating machine |

| Three | Classification of workpieces could be heated |

| Four | Frequency asked question during the operation of machine |

Advantages of our induction heating machine

One:The workpieces could be heated both partly and intergral

Two:The inductors produced according to your special workpieces

Three:The German technology IGBT adopted by our own factory

Four:Multi-Function, the workpieces could be Quenching/ Hardening/ Forging/ Melting/ Brazing/ Welding/ Diathermy

Five:environment protection, no noise, electric energy saving than traditional heating equipment.

Quenching/ Hardening workpieces as follows:

One |

Quenching/ Hardening auto parts, motorcycle accessories, wheel, camshaft, gears, crankshaft, connected rod, piston pin, crank pin, valves, and etc |

| Two | Quenching/ Hardening various power gears, sprockets, all kinds of shafts, spline shafts, axle mass and etc. |

| Three | Quenching/ Hardening all kinds of hydraulic components, preumatic compenents, the piston of the column and etc. |

Melting/ Welding/Brazing main specifications capacity as follows:

The parameters is maxinum melting capacity at a time, the melting temperature could be reach about 2200 degree, also,

Welding the diamond saw, drill, carbide tools,bits, coal drill bits, pick, turning, planing, milling, and welding varieties of wood working tools.

Melting Furnace Model |

Steel and stainless steel |

Copper, gold, silver |

Aluminum |

| 30kw | 2kg | 10kg | 3kg |

| 40kw | 5kg | 20kg | 6kg |

| 50kw | 10kg | 30kg | 10kg |

| 60kw | 18kg | 50kg | 20kg |

| 80kw | 25kg | 100kg | 30kg |

| 120kw | 50kg | 150kg | 50kg

|

Forging/ Diathermy workpieces as follows

One |

Plate heating, bending and forming, such as: brass, steel strenching bending, smashing head wire, heating wire nail, stainless steel and ec |

| Two | Standard parts, fasteners through the hot forging, such as the hardware through heat, pliers, wrenches and other heat through hot forging. |

| Three | Real axle and hot Forging, rotor, and other parts of the thermal loading. |

Packing&Shipping:

Two wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air.

Our service:

The electromagnetic induction heating machine we produced for some years, and the engineers available service overseas is supported

One |

Engineers availabe to service overseas. |

| Two | The delivery time would be only 3-7 days if there is stock. |

| Three | The warranty we supported is free replacements spare parts for 12 months |

| Four | Transportation we supported is shipping by sea, by air, by express DHL. |

| Five | Payments:L/C, T/T, D/P, D/A, Western Union, MoneyGram, Paypal, Cash is allowed |

FAQ

Why Choose Us

1. over 15 years eperience in induction heating field

2. heating furnace is safety and reliability, long life

3. our heating equipment export to Italy, Mexico ,Turkey, Slovakia, Pakistan, Iran,Vietnam,India, Malaysia,Brazil ,Indonesia,South Africa,etc. And winning great popularity

4. one year warranty and life-time technology support

5. fast, timely delivery & reliable after-sales service

6. spare parts & tools delivered with harvester for daily maintenance

7. customers & quality first.

Contact us:

Mobile phone: +86 18937170169

Website:http://www.induction-heatings.com

Member Information

| Zhengzhou Gou's Electromagnetic Induction Heating Equipment Co., Ltd. | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18937170169 |

| Contact: | Anna Liu (Foreign Trade) |

| Last Online: | 14 Sep, 2018 |

Related Products of this Company

-

High Frequency Milling Cutter Induction

US $2200

-

CNC Gear Shaft Induction Quenching

US $12000

-

20kw Ultra High Frequency Induction

US $5500

-

60kw Ultrahigh Frequency Shaft Surface

US $15000

-

Portable Industrial Metal Heating

US $2200

-

High Frequency Petroleum Special Pipe

US $11000

-

Supersonic Frequency 80KW Induction

US $5500

-

High Efficiency 30KW IGBT Aluminum

US $2200

-

Medium Frequency Standard Parts

US $13000

-

High Efficiency 60kw Induction Quenching

US $4200