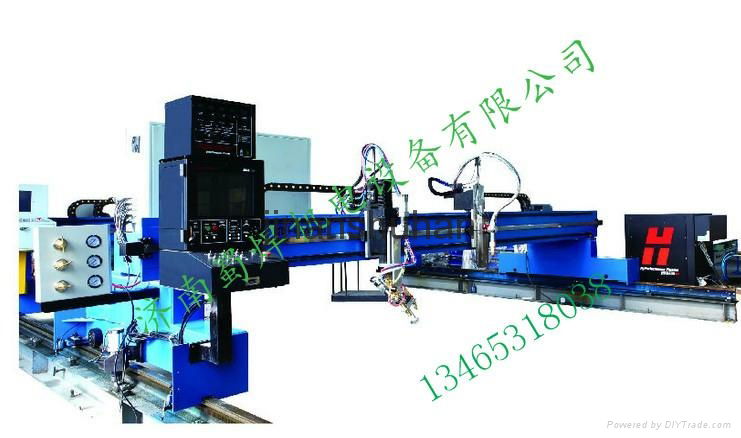

CNC plasma cutting machine

Summary:

Its main features are stable performance, stable operation, high positioning accuracy and simple appearance. The modular design makes the machine parts interchangeable and the function extension is very simple. The user can configure corresponding functional components according to the actual process requirements, such as flame single cutting torch, flame linear three-cutting torch, automatic height adjustment, high and low pressure three-stage perforation, automatic ignition, etc. The machine is widely used in petrochemical industry, shipbuilding, steel structure, automobile manufacturing and other industrial fields. It is a reliable and efficient industrial product for the materials under plate. (see the diagram below for the schematic diagram, in detail)

4.2. Introduction to structure:

This series of cutting machine is mainly composed of host door frame, transverse and longitudinal drive drive, heavy cutting torch lifting device, longitudinal guide device, the energy supply system, electric control system and other components.

4.2.1. Main frame: (including main beam, main end bracket and auxiliary end bracket)

Main beam: the 8 mm thick steel plate structure of welded box (box cross section size is 250 mm * 600 mm), used when welding the discontinuous welding automation plane, greatly ensure the weld quality, effectively reduce the welding deformation. After being good beam welding, whole annealing treatment (annealing temperature is 650 °, natural furnace cooling), to eliminate the welding stress completely, ensure the accuracy of the associated beams after precision machining accuracy and durability.

The main end frame and the auxiliary end frame are welded and formed by steel plate, and the whole annealing process after the welding and welding of the main and auxiliary ends is completed, which guarantees the accuracy and durability of the precision machining back-end. The central position of the main terminal is equipped with a longitudinal drive device, which is installed in the center of the machine to ensure the stability of the machine. All the key structures of the door frame were treated with the surface shot blasting after forming, and all the key structural parts adopted the whole annealing stress treatment. The accuracy after processing is guaranteed, and the surface quality after painting is improved. (right: linear guide, steel belt transmission mechanism, horizontal limit bump)

If cutting machine is equipped with multiple sets of CNC cutting torch, the two ends are respectively in beams with steel belt transmission device, main mobile body and vice moving body through the steel belt transmission device is, the clamping, relationship between the cutting torch mirror to smooth movement. The beam is equipped with a horizontal limit switch and a machine horizontal reference point.