| Model: | - |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Energy / Petroleum |

| Label: | - |

| Price: |

-

|

| Min. Order: | - |

Product Description

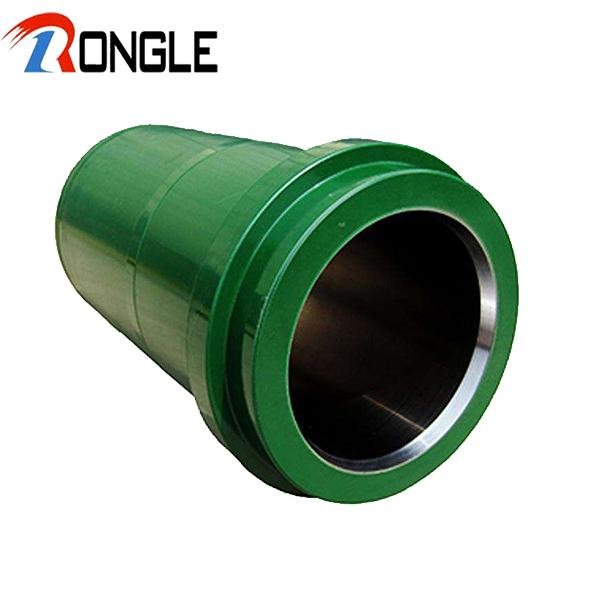

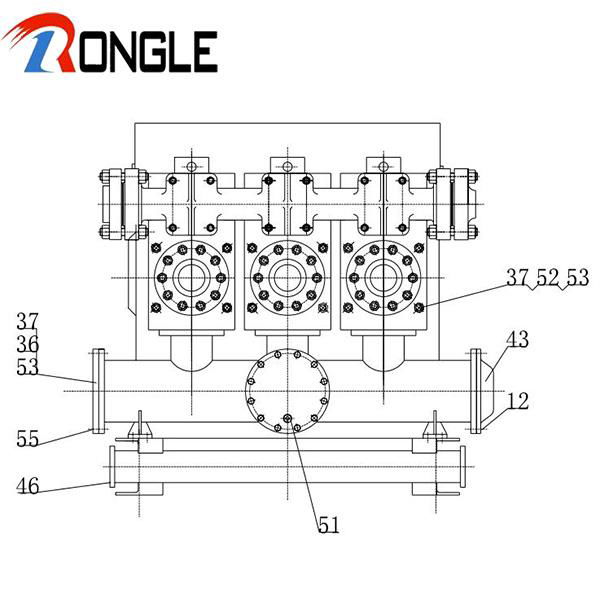

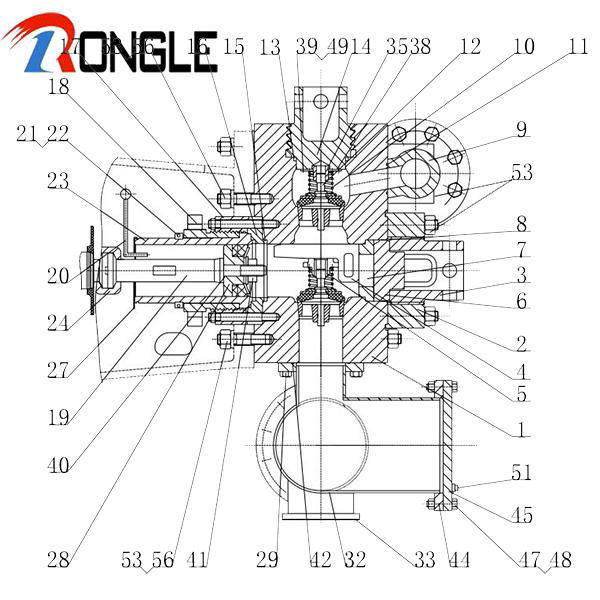

LINERS

Material: High chrome alloy sleeved, ceramic zirconia.

Sizes: 4 to 7-1/2 inches.

Standard: API-7K.

Hardness: 62-69 Rockwell

High Chrome Sleeve Liners(Item 23)

RONGLE’s High Chrome Sleeve Liners are the most popular type of liners used by in the drilling fields. These cost-effective chrome-iron liners offer outstanding durability. The hybrid design of these liners combine the toughness of a high strength forged- steel outer hull with the hardness and corrosion resistance of a centrifugally cast, high-chrome-iron inner sleeve.

The outer hull or shell, is manufactured from high strength carbon or alloy steel and heat-treated to provide optimum mechanical properties. CNC machined to provide exacting tolerances to keep liner concentric of the inner bore in relationship with the outer guide diameters on the hull. This reduces the possibility of misalignment on installation and provides the end user with longer liner and piston life.

The sleeve has excellent abrasion and corrosion resistance. It is through hardened during heat treat to provide high material hardness at all depths throughout the material. The sleeve is manufactured to the bore tolerances specified by API or better to provide longer life by reducing gaps between the liner bore and piston.

Features & Advantages

Rated for all drilling operations ≥5,000 PSI.

Consistent bore hardness: 62 to 69 RC (Rockwell C Hardness)

Extremely long service life: 800-1000 hours.

High Strength & Tough forged steel outer hull

High Chrome alloy inner sleeve honed to tight tolerances and mirror finish to promote maximum piston life.

Ceramic Zirconia Liners(Item 23)

RONGLE’s Zirconia-ceramic liner is our premium and better performer product. It offers unique durability and promotes the longest piston life in extreme drilling conditions. Effectively resistant to heat, pressure, and corrosion, it is the ultimate in liner technology available today. Although initial costs are higher than traditional chrome-iron liners, the durability of the liner and the longer run times it promotes on pistons, equates into lower overall costs.

RONGLE’s Zirconia-ceramic liner is produced from a unique Zirconium-based ceramic compound that is extremely pure. This proprietary fine-grain structure Zirconium-based matrix is free of the impurities that affect lesser products. No other ceramic-liner material has better fraction toughness, which enables us to offer a ceramic liner that is hard and long lasting, tough, crack resistant, and not susceptible to thermal shock.

Zirconia has three important property advantages over alumina ceramic liners.

1. Zirconia is harder and less brittle than alumina.

2. Zirconia shows better impact strength.

3. Zirconia can be honed to finer surface finishes than alumina. Finished to 4 RMS, the zirconia liners provide a surface finish that is three to four times finer than alumina.

Features & Advantages

Directly extends the service life of the sleeve, (Hours of service: 4000-5000 hours)

Reduces significantly the costs of replacing broken liners in the field

Less friction with the elastomer-and-metal pump pistons translates into reduced liner and piston wear Increased impact characteristics.

Lower thermal load on the liner wash system.

Higher thermal ratings.

Improved performance for high temperature applications.

Zirconia offers the lowest overall cost of ownership of any liner style

Member Information

| shaanxi rongle petroleum machinery co.,ltd. | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 17782981610 |

| Contact: | Tony Fan (Manager) |

| Last Online: | 30 Mar, 2018 |