| Model: | - |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Energy / Petroleum |

| Label: | - |

| Price: |

-

|

| Min. Order: | - |

Product Description

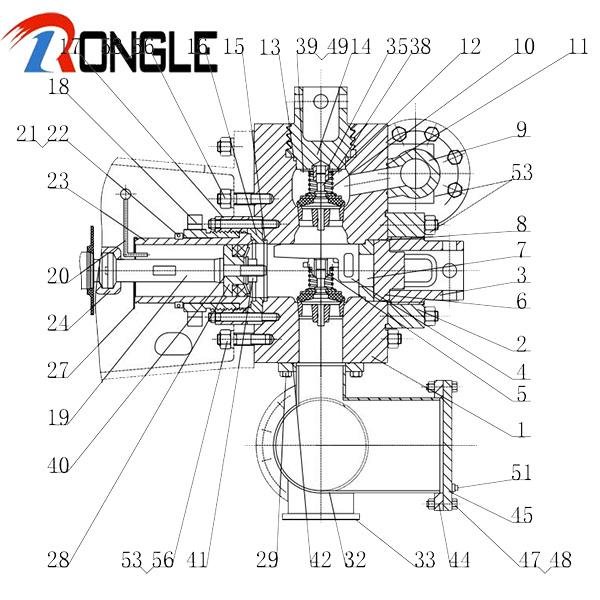

VALVES and SEATS

RONGLE’s valves and seats (Item12) are made of forged alloy steel with deep carburized wear surface, precision machined to API standards. The valves and seats we offer have two major categories, full open valves and seats, 3 web / 4 web valves and seats.

Full Open Valves and Seats

RONGLE’s full-open valve is the top performing valve available for the extreme conditions seenin today’s drilling environment. The single-piece, solid-body construction of this valve provides the strength and rigidity needed for high-pressure drilling operations in the 5,000- to 7,500-psi range. Both the valve and the seat are manufactured from heat- treated, forged-alloy steel.

The fully open seat design enables removal of suction- valve seats without first removing the discharge valve seats for easy access on valve-over-valve-style fluid ends. This process can result in significant time and labor savings when only a suction-valve seat requires replacement. The seat does not have the three or four internal support webs that are common on other valve styles, and the result is a uniform distribution of pressure across the entire diameter of the fluid-cylinder valve taper, which reduces the chance of seat washout and prolongs the life of the module.

The slip on or snap-on, urethane insert on the standard valve is field replaceable. For the most demanding high-pressure conditions, a non- replaceable bonded insert upgrade is available that resists extrusion and minimizes any chance for lost-circulation material or other debris to breach the seal cavity. All standard inserts are available in urethane and are good for 170° to180°F drilling temperatures. We have available a special, high-temperature compound for drilling-mud temperatures to 200°F and higher.

Features & Advantages

The forged, solid valve-body construction of this valve, with thick, rigid seat, provides durability at high pressures.

The streamlined valve guide wings reduce turbulent flow through the valve for improved performance.

The seat design simplifies maintenance and evenly distributes pressure loads around the fluid-cylinder valve taper.

Various insert styles and materials are available to suit any drilling condition.

Carbon-steel valve springs are standard. A long-life, stainless-steel upgrade is available.

Large metal-bearing area on the valve seat seal surface promotes longer service life.

3 & 4 Web Valves and Seats

Three Web

The center- guided design of the three web enables the valve flange to be supported under pressure loads by the top of the center support webs in addition to the seating taper on the inside of the valve seat. This process allows for a large bearing area for the valve that minimizes stress and promotes a long service life.

The single-piece, solid-body construction of these valves 3 web design, provides the strength and rigidity needed for high-pressure drilling operations. Both the valve and seat are manufactured from heat- treated, forged-alloy steel.

The unique design of the insert helps seal fluid above the valve, even when the pump is not in operation and pressure is not available to energize the seal. This design helps to maintain prime and ensures that a good supply of mud is available to the piston—even on the first stroke of operation after extended shutdown periods. Special lips in the insert groove of the valve body lock the lip in place, eliminate washout potential, and minimize any chance for loss-circulation or other foreign materials to breach the seal cavity.

The snap-on, urethane insert can be replaced in the field. The valve is offered standard with a urethane insert suitable for mud service between 170° and 180°F A high-temperature urethane insert is available as an option for mud temperatures to 200°F and higher.

Features & Benefits

The forged, solid-body construction provides durability at high pressures.

The large bearing area on the valve seat webs promotes a long service life.

Various insert styles and materials are available to suit any drilling condition.

Carbon-steel valve springs are standard.

A long-life, stainless-steel upgrade is available.

The valve is best suited for low- to medium-pressure drilling operations because of the two-piece assembly of the valve body

Four Web

The key feature of the four-web, center-guided valve is the preloaded urethane insert secured with a threaded retainer plate with knock-off lugs for easy disassembly. This design enables drillers to change valve inserts quickly and minimizes downtime. The valve is best suited for low- to medium-pressure drilling operations because of the two-piece assembly of the valve body.

The center-guided design enables the valve flange to be supported under pressure loads by the top of the center-support webs in addition to the seating taper on the inside of the valve seat. This allows for a large bearing area for the valve that minimizes stress and promotes a long service life.

Our standard valve is offered with urethane inserts rated for 170° to 180°F drilling-mud temperatures. We also offer a special high-temperature urethane compound as an option for high-temperature drilling conditions to 200°F and higher.

Features & Benefits

The threaded retainer plate with knock-off lugs enables fast insert change-out The large bearing area on the valve promotes a long service life.

Various insert materials are available to meet standard and high- temperature drilling conditions.

Carbon-steel valve springs are standard, with a long-life, stainless-steel upgrade available.

Member Information

| shaanxi rongle petroleum machinery co.,ltd. | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 17782981610 |

| Contact: | Tony Fan (Manager) |

| Last Online: | 30 Mar, 2018 |