Key Specifications/Special Features:

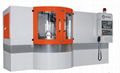

Machine features:

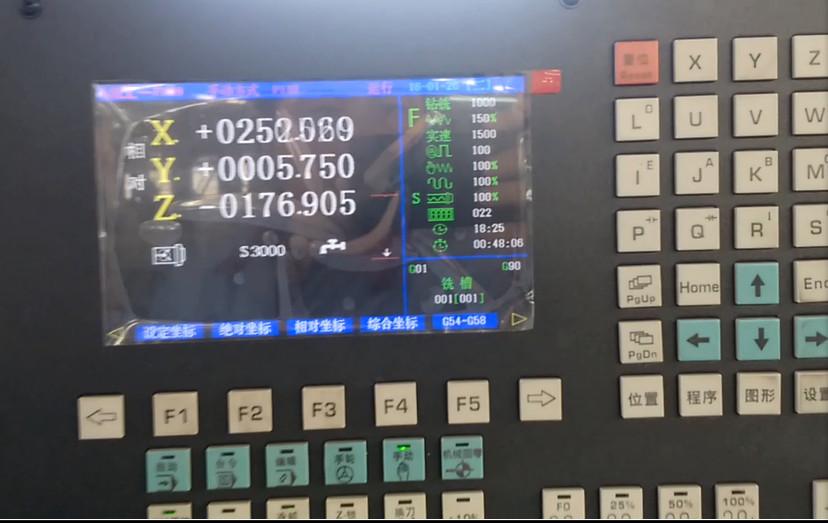

- One key to switch drilling or slotting mode

- High-drilling, slotting precision, reduce additional process

- User-friendly operation, easy control

- Whole piece casting worktable, enhance loading capacity

- Changeable BT30 tool holder, pneumatic tool unclamping cylinder, quick tool changing

- Special fixture, self-centering

- Motor professional specialized CNC system ensures the reliability and stability

- Long Z axis stroke, suit for machining of different thickness

Service item:

1. Machine warranty period is 12 months once the customer receives the machine, after 12 months, we may answer the customer's question online or by E-mail within 24 hours

2. Mltor will prepare one more set of quick-wear components with the machine for the customer

3. Mltor will not provide or change any part or component for free if the customer damages them abnormally, customer's needs to purchase them separately

4. Mltor will afford the customer's technician local transportation, accommodation and catering cost when the customer's technician comes to Mltor factory to have a train or inspects the machine before the machine delivery and the customer will afford their technician traveling cost

5. In the warranty period, if the customer requests Mltor engineer to support in foreign country, Mltor will support to check equipment and train the customer technician for free but the customer's needs to afford Mltor's engineer traveling expenses, local transportation, accommodation and catering cost

| MLT-F1515 main specifications |

| Forward and backward travel range |

1500x1500mm |

| Workbench space |

1500x1500mm |

| Axis Z travel range |

550mm |

| Height of flange feeding |

880mm |

| Spindle specification |

BT30 |

| Spindle speed |

0-3000rpm |

| Scope of drilling |

Ø30mm |

| Cutter tool change |

Pneumatic cutting |

| Clamping path |

T-groove+ pressing plate |

| Spindle power |

5.5kW |

| Machine total power |

10kW |

| Positional accuracy |

0.01mm |

| Main components |

| Lead screw with precision grade |

HIWIN/TBI/PMI, Taiwan brand |

| Linear guide rail with precision grade |

HIWIN/TBI/PMI, Taiwan brand |

| Axis Y linear screw rod protection |

Heavy load steel plate protection, protect direction Y screw rod clean effectively |

| Axis X linear screw rod protection |

Organ protection, protect direction X screw rod clean effectively |

| spindle frequency |

CTB |

| Electronic control |

Schneider |

| Terminal |

Phoenix |