| Model: | SX8000,SX5000 |

|---|---|

| Brand: | sanxin |

| Origin: | - |

| Category: | Industrial Supplies / Machinery / Spraying Machine & Spreading Equipment |

| Label: | HVOF spray machine , powder coating , tungsten carbide |

| Price: |

US $21000

/ pc

|

| Min. Order: | 1 pc |

Product Description

With the effort of our skilled professionals, we have developed an extensive assortment of HVOF Powder Spray System. This spray system is ideal to be used in medium to large projects which require high volume surfacing and enhanced quality control. Our products are popular of their high quality and low price.

SX-8000/SX-5000 HVOF spray machine(HVOF coating machine) insists of :Control cabinet, Spray gun, Water chiller, Kerosene storage tank and Pipelines connection system, etc

1.component of tungsten carbide powder HVOF coating machine

(1).Control cabinet

Control cabinet is the control center of supersonic spray system, which uses the current hightech and automatic controls for the entire spray system . HVOF spray equipment can get the advanced level of similar foreign products, superior performance, ease of operation. Control cabinet adopts touch control terminal to put operation/ setting/display/ process and fault alarm monitoring together, simplifying panel design, easy to use, simple operation and intuitive.

(2)Powder feeder for HVOF spray machine(HVOF coating machine)

Powder feeder for HVOF spray machine(HVOF coating machine) is a device that used to store spray powder according to process requirements to deliver powder to the gun . Nitrogen is the powder feeding gas. Spraying powder through a gas atomization vibration so that the powder feeding device to exit, along with to send powder gas left to send powder barrels into the spray gun.The powder feeding speed can be adjusted by adjusting potentiometer on control panel.

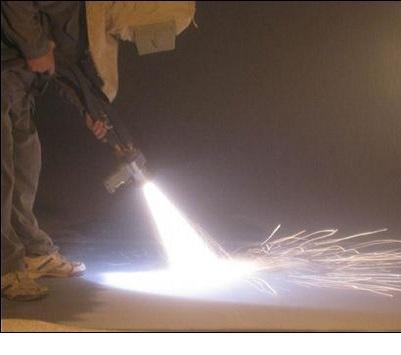

(3)Spraying gun for HVOF spray machine(HVOF coating machine)

SPRAY GUN FOR SX8000

SPRAY GUN FOR SX8000  SPRAY GUN FOR SX5000

SPRAY GUN FOR SX5000

Spray gun uses kerosene as fuel, oxygen as the combustion gases, air and water for the cooling body, nitrogen for feed powder. This gun can be working with a long continuous stability.

Parameter for Spray gun of HVOF spray machine(HVOF coating equipment)

|

No. |

Items |

Basic parameter |

|

1 |

Flame speed |

About 2100m/s |

|

2 |

Flame temperature |

About 5000℃ |

|

3 |

Gun Power |

150KW(Conversion value) |

|

4 |

Powder particle velocity |

1100 m/s |

|

5 |

velocity |

Water cooling |

|

6 |

Cooling water flow |

9.5L/min |

|

7 |

Coating porosity |

<1% |

|

8 |

Coating bond strength |

>90MPa |

|

9 |

Suitable powder size |

10-45μm |

|

10 |

Fuel pressure and flow |

1.2MPa 0~60L/min |

|

11 |

Oxygen pressure and flow |

1.6MPa0~60m3/H |

|

12 |

Nitrogen pressure and flow

|

0.35~0.4MPa 3~15L/min |

|

14 |

Dimensions |

90mmX100mmX350mm |

|

15 |

Weight |

About 4.5Kg |

(4)Water chiller for HVOF coating machine

Dual compressors drive can reduce the overall volume and increase your space.It mainly used to let the gun to get efficient cooling.We choose temperature controller imported with highprecision digital display to control accurately the temperature at ± 1 ℃ and range 3 ℃ ~ 45 ℃.

HVOF Spray series models:

|

HVOF Spray Equipment |

SX-5000 |

SX-8000 |

||

|

Coating Material |

Carbon Tungsten, Nickel Chromium Carbide, etc |

Carbon Tungsten, Nickel Chromium Carbide, etc |

||

|

Combustion medium |

Oxygen & Propane |

Liquid Oxygen & Kerosene |

||

|

Airflow Parameter |

Pressure (mpa) |

Flow(m3/h) |

Pressure (mpa) |

Flow(m3/h) |

|

Fuel |

0.7-0.9 |

1.0-1.8 |

0.2-0.3 |

35-70 |

|

Oxygen |

0.7-0.9 |

1.2-2.0 |

1.5-1.9 |

150-180 |

|

Powder Feeding Gas |

0.6-0.8 |

0.5-0.7 |

0.6-0.8 |

20-30 |

|

Compressed Air |

0.7-0.9 |

2.0-2.5 |

|

|

|

Powder Feeding Velocity |

3-6kg/h |

4-8kg/h |

||

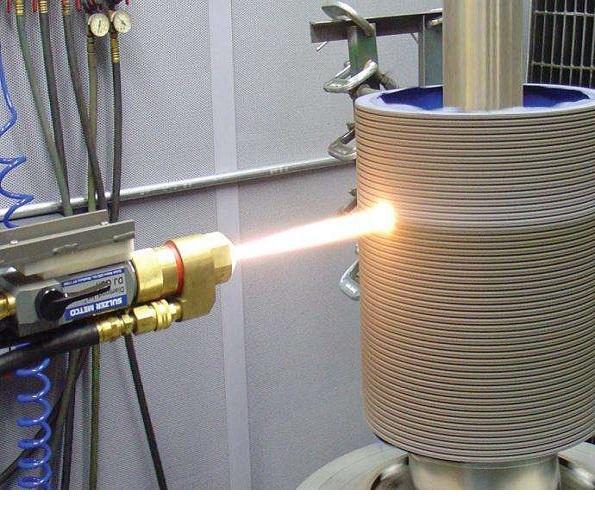

2.principle of tungsten carbide powder HVOF coating machine

the combustion supporting agen oxygen atomizes the kerosene fully with atomizing nozzle, then they will enter into combustion chamber as flammable mixed gas.It will burn in high temperature and high pressure after the ignition system ignites it. high-temperature and high-pressure supersonic flame flow will be formed after it’s burning in the Laval nozzle. powder feeding system will send the powder material from the area of low pressure into the flame flow, heating accelerated then spray to the workpiece surface to form high quality coatings.

3.characterics of tungsten carbide powder HVOF coating machine

HVOF coatings may be as thick as 12 mm (1/2"). It is typically used to deposit wear resistant and corrosion resistant coatings on materials, such as ceramic and metallic layers. Common powders include WC-Co, chromium carbide, MCrAlY, and alumina. The process has been most successful for depositing cermet materials (WC-Co, etc.) and other corrosion-resistant alloys (stainless steels, nickel-based alloys, aluminium, hydroxyapatite for medical implants, etc.).

Coating Features:

High Density

Optimum Hardness

Smooth Surface

High bond Strength

Excellent wear resistance

Reduced Oxide content than plasma coating

4.characterics of tungsten carbide powder HVOF coating machine

(1)Our HVOF series sprayer equipment is easy for operation and use. Operator only needs to control a few buttons to manage the spraying process. Spraying efficiency is very high

(2) Coating of our HVOF has low porosity and high bond strength.

(3) Our equipment control unit is developed from advanced design of the automation feature, which allows operator to control the real-time process with the system and the spray gun

5.about our company

our factory is specialized in spraying construction,coating services,and spraying equipment for more than 30 years ,we are Senior member of China thermal spray association ,we have the first class construction certificate of thermal spray ,all our products are of good quality and competitive price. we have dozens of spraying equipment ,such as thermal spraying equipment,arc spraying equipment ,plasma spraying equipment ,and so on

6. application and advantage of tungsten carbide powder HVOF coating machine

HVOF machine is widely used in spraying Tungsten carbide ,NiCr chrome carbide and Nickel chrome aluminum on the workpieces ,to improve the abrasion resistant ,wear resistant and corrosion resistant of the surface of the workpieces .Here I will discuss more about HVOF Tungsten carbide sprayer on cathode material equipment and lithium battery equipment

(1) HVOF Tungsten carbide sprayer can be used in such respect of cathode material :mixing material equipment and pipe,abrasing material equipment and pipe ,conveying equipment and pipe

(2)HVOF Tungsten carbide sprayer can be used in wearable workpieces of lithium battery equipment ,such as screw,pipe,elbow,barrel ,mixer shaft and cone hopper (3)hardness of HVOF Tungsten carbide sprayer can reach HRC75,bonding stretch can reach 600kg/cm2(4)avoid cathode material powder from pollution ,far away from the basic iron impurity (5) our company adopt Americal PRAXAIR equipment ,and choose the inward Tungsten carbide material ,so our HVOF machines are of advanced technology and reliable quality

7.other equipment for reference

If you are interested in our machine,please contact me, I will offer you more details accordingly,thanks

Member Information

| Guangzhou Sanxin Metal Co.,LTD | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18126811739 |

| Contact: | Jessica (manager) |

| Last Online: | 24 Aug, 2018 |

Related Products of this Company

-

metal alloy or ceramic coating plasma

US $23000

-

2mm zinc aluminum copper arc coating

US $4800

-

1.6~3.2mm molybdnum metal alloy wire

US $4000

-

Electric arc spray machine for spraying

US $4000

-

zinc coating arc spray machine, arc

US $4800

-

ceramic coating imported plasma spray

US $9000

-

zinc aluminum copper wire arc spray gun

US $900

-

arc spray coating machine, titanium

US $4000

-

arc spray zinc aluminum wire arc coating

US $4800

-

2mm copper metal alloy wire arc

US $4000