| Model: | SX600 |

|---|---|

| Brand: | sanxin |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Spraying Machine & Spreading Equipment |

| Label: | arc spray machine , zinc coating , aluminum coating |

| Price: |

US $4800

/ pc

|

| Min. Order: | 1 pc |

Product Description

Are you looking for the zinc aluminum alloy wire arc spray machine ? Do you have difficulties in dealing with the broken workpieces ? Maybe our arc spra machine(twin-wire arc spray equipment) SX600 can help you .

our factory is committed to spraying technology research for more than 30 years ,we have dozens of spraying equipment ,such as thermal spraying equipment,arc spraying equipment ,plasma spraying equipment ,and so on

SX-600 is one kind of arc spraying machine, it is used for spraying zinc,aluminum,copper,molybdnum,titanium,stainless steel,high carbon steel,nickel chromium alloy,wear-resistant alloy,Babbitt alloy material,zinc aiuminum alloy,etc.

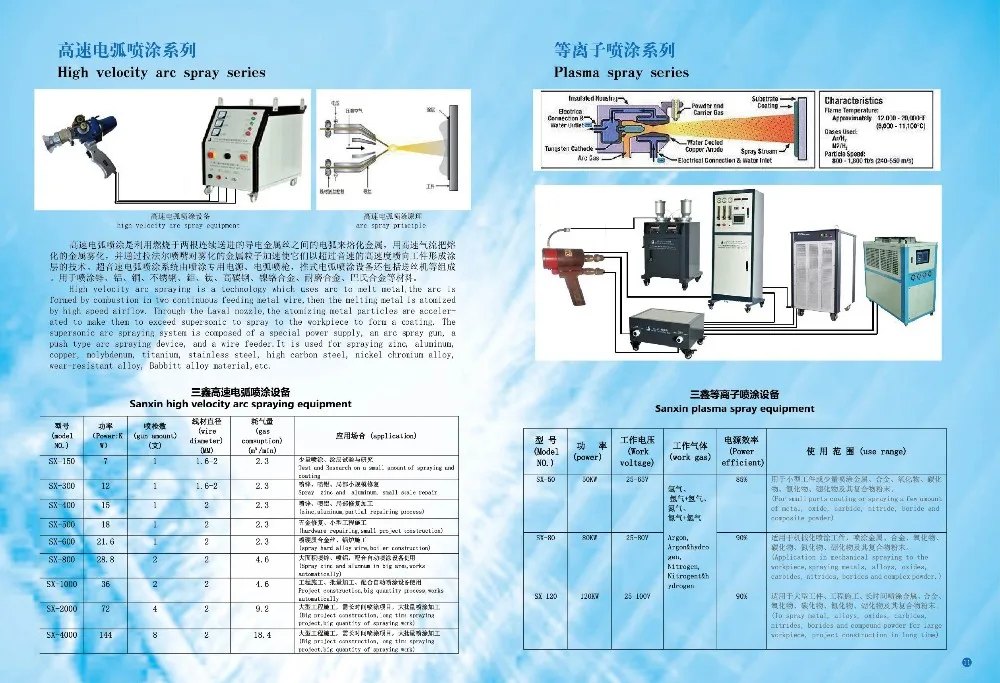

(1) principle of zinc aluminum alloy coating arc spray machine SX600

This high velocity arc spraying (high velocity arc spraying) is a technology which uses arc to melt metal,the arc is formed by combustion in two continuous feeding metal wire,then the melting metal is atomized by high speed airflow.Through the laval nozzle,the atomizing metal particles are accelerated to make them to exceed supersonic to spray to the workpieces to form a coating.

(2)component of zinc aluminum alloy coating arc spray machine SX600

It is a new technology based on the normal arc spraying ,which is composed of a special power supply, an arc spray gun, a push type arc spraying device, and a wire feeder.

arc spray machine arc spray gun

(3) parameter of zinc aluminum alloy coating arc spray machine SX600

Arc spray gun parameters:

|

Model |

Arc spray gun |

|

Operation mode |

Handed or fixed |

|

Input voltage |

≤24V(DC) |

|

Applied wire diameter |

Φ1.2 Φ1.6 Φ2.0 Φ3.0 mm |

|

Air pressure |

>0.5Mpa |

|

Air consuming |

>1.85m3/min |

|

Wire feeding gravitation |

>8kg |

|

Feeding velocity regulating grade |

Stepless speed regulating |

|

Weight |

2.65kg |

Metal wire parameters:

|

Spray material |

Wire diameter |

Working current |

No-load volt |

Air hat diameter |

Maximum spray efficiency |

|

Zinc wire |

1.2-3.0 |

80-210 |

18-30 |

6-8 |

30 |

|

Al wire |

1.2-3.0 |

120-240 |

25-38 |

6-8 |

9.5 |

|

Steel wire |

2.0 |

150-200 |

35-40 |

7-8 |

6 |

|

High carbon steel wire |

2.0 |

150-220 |

10-44 |

8 |

5.5 |

|

Stainless steel wire |

2.0 |

150-220 |

10-44 |

8 |

5.5 |

|

Zn-Al, Pb-Sn alloy wire |

1.2-2.0 |

80-110 |

18-28 |

7 |

|

(4)advantage of arc spray machine SX600

1) Stable and convenient

This equipment is improved in the operation program by integrated circuit to prevent from machine damage by misoperation of workers, so as to protect the safety of operators and the equipment.

2) High adhesive force of coating(70Mpa)

Compared with 30-40Mpa of common arc’s coating,the adhesive force of coating can reach 70Mpa.

3) Workpiece won’t be deformed and its structure won’t be changed.(<100℃)

Generally the rised temperature of workpiece won't exceed 100 ℃ when spraying, so the workpiece won't be deformed. And the spraying heat won't take effect directly on the surface so it doesn’t change the structure of workpiece.

4) High efficiency and wide application

The equipment has high spray efficient and high power; It's suitable for on-site construction, and can use all kinds of metal and metal ceramic materials(solid and without core), such as alloy wires, Mo, Al, Zn, red copper, copper alloy, Babbitt etc. It is widely applied in spraying anti-wearing and anti-rust coatings for boiler’s four kinds of tubes, coal pulverizing system (fan impeller and scroll casing), roller, dryer, axis, mould,all kinds of workpieces and so on.

5)Spray gun for long distance(30-meter-long-cable)

The spray gun can be equipped with 30-meter-long cable, air tube and 8-core control cable, so it can spray at remote places about 30 meters from the equipment.

6)Unnecessary to change the wearing parts frequently

We have patent conductive nozzle which is anti-wearing and greatly enlarges use time of wearing parts. This helps to reduce the spraying cost and improve working’s efficiency and coating’s quality.

7)Convenient maintainance and repair

We take maintainance and repair work into our consideration during designing the equipment and spray gun which make it convenient to maintain and repair.

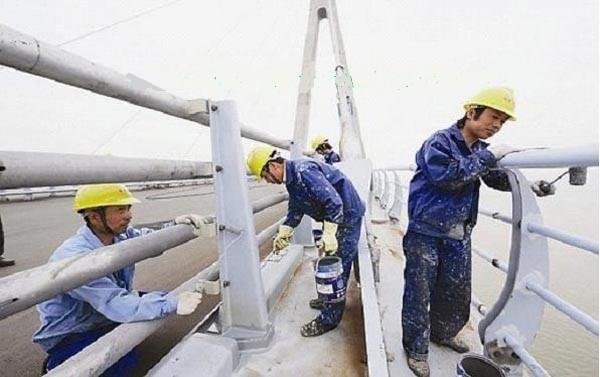

(5)application :

can spray the yellow copper ,bronze copper ,red copper, zinc aluminum alloy,tin-based babbitt alloy, aluminum bronze,austenitic stainless steel, martensitic stainless steel, heat resistant alloy,zinc, aluminum,zinc aluminum alloy on the surface of the workpieces.

(6)our service:

we can offer you the user manual to help you start the machine ,also,our technologist can go abroad to instruct you , also, we can send you live video by wechat ,in fact ,most of our foreigner customers make it by our manual and video successfully

If you are interested in our arc spray machine(twin-wire arc spray equipment),please contact me ,I will offer you more details accordingly ,thanks

Member Information

| Guangzhou Sanxin Metal Co.,LTD | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18126811739 |

| Contact: | Jessica (manager) |

| Last Online: | 24 Aug, 2018 |

Related Products of this Company

-

1.6~3.2mm metal wire coating arc spray

US $4000

-

tungsten carbide powder HVOF coating

US $21000

-

zinc coating arc spray machine, arc

US $4800

-

ceramic coating imported plasma spray

US $9000

-

2mm zinc aluminum copper arc coating

US $4800

-

2mm copper metal alloy wire arc

US $4000

-

zinc aluminum copper wire arc spray gun

US $900

-

Electric arc spray machine for spraying

US $4000

-

metal alloy or ceramic coating plasma

US $23000

-

2mm aluminum metal alloy wire arc

US $4000