| Model: | P36 38 |

|---|---|

| Brand: | rapicoat |

| Origin: | Made In China |

| Category: | Chemicals / Coatings, Varnish & Painting |

| Label: | polyester putty , car body repair putt , 1k primer |

| Price: |

US $5.05

/ liter

|

| Min. Order: | 350 liter |

Product Description

we are professional automotive car paints manufacture included:

1,auto base car paints

2,vanish paint

3,2k epoxy topcoats

4,1K Auto Refinish Paint

5,2k primer surfacer

6,polyester putty

7,2k acrylic clearcoat

weather resistance good coverage good filling ability ,good match to original with favourable price.

expect further coopearton!

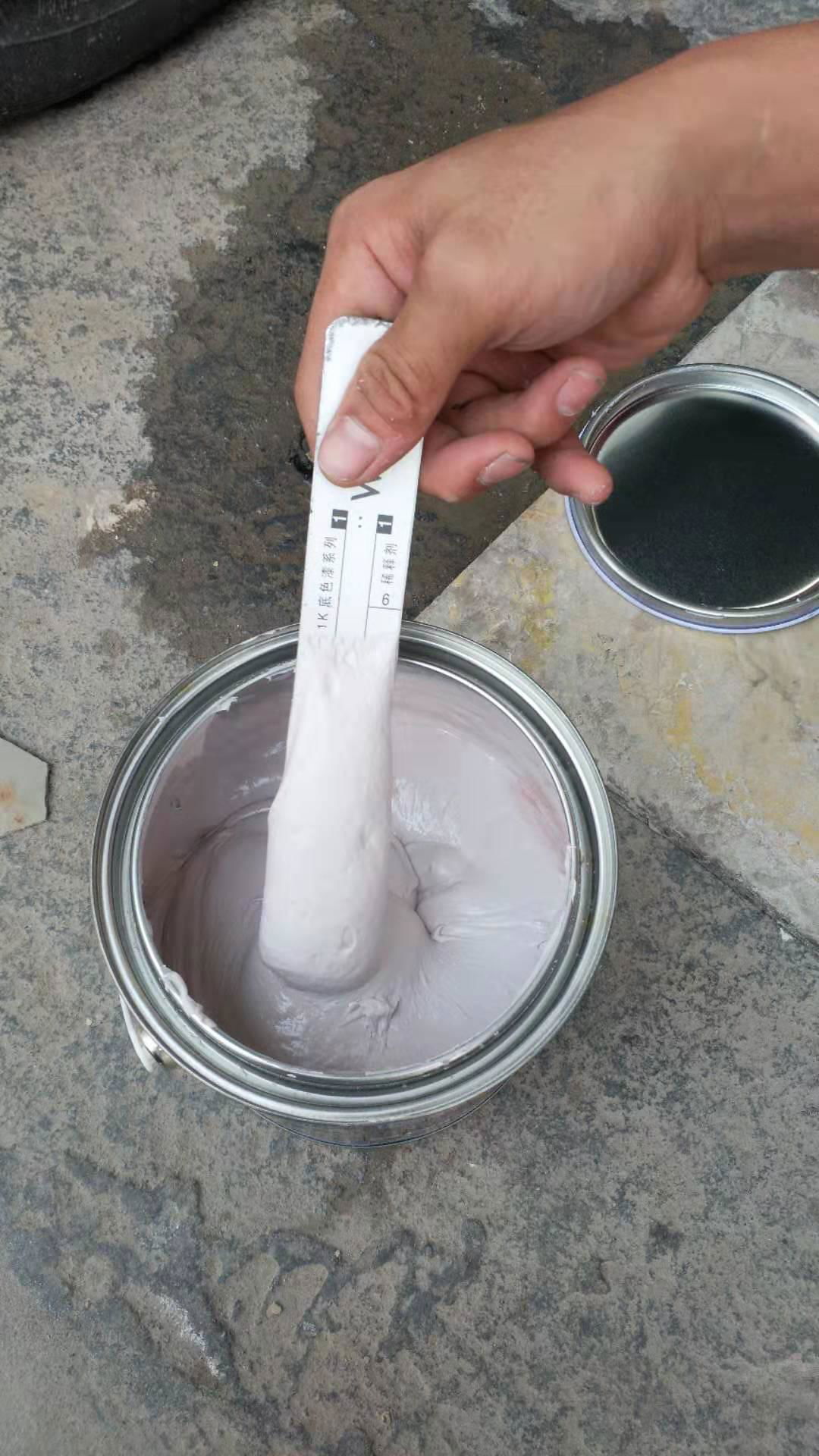

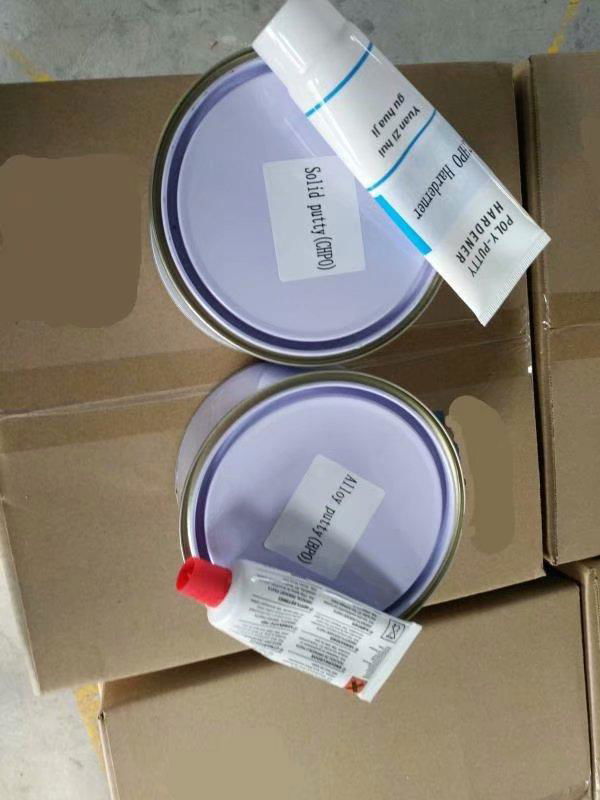

| RAP-36 polyester putty | ||||||||

| Characteristic | Two component polyester putty to fill dents and surface irregularities.

Polyester Putty Multifill is a multi-substrates putty and gives very good adhesion on various substrates like: steel, zinc coated and aluminium surfaces. It is easy to mix and apply. Its fine texture gives it a very smooth surface making it easy to sand two-pack polyester putty. It is used for filling the pits, scrape uneven metal surface |

|||||||

| Substrates | Epoxy primer,steel surface,Polyester Putty Multifill Perfect filling on zinc, aluminum and steel | |||||||

| Substrates Treatment | Remove the rusted phosphor,oil,old paint film,and water completely with solvent and sanding machine. | |||||||

| Mixing ratio(by weight) | RAP-36: 100 parts Special hardener: 2~3 parts | |||||||

| Pot Life | 8-15 minutes@20℃ | |||||||

| Drying Time | 50-60 minutes@20℃ | |||||||

| Sandability and Polishabiility | Sanding roughly by P80-P180 sanding paper

Sanding completely by P180-P320 sanding paper |

|||||||

| Shelf Life | 6 months since the production date if sealed and kept in a cool and dry place | |||||||

| Package | 4kgX4tins/ctn | |||||||

| 2K solid color B series | ||||||||

| 2K senior two-pack solid color, with properties of hard paint film, high gloss and build with good resistance and hiding power. The color is bright and long lasting. | ||||||||

| Substrates | Dried and sanded existing finishes or primer | |||||||

| Substrates treatment | Remove paint dust and contaminations with degreaser | |||||||

| Mixing Ratio | Name | 2K Solid color | Hardener | Thinner | ||||

| Volume

Ratio |

100 parts | 50parts | 20-30parts | |||||

| pot life | 4 hours@20degree | |||||||

| Spray viscosity | 16-22 Seconds@20 degree | |||||||

| No. of Coats | 2-3 coats | |||||||

| Flash-off time | 10-15 Minutes | |||||||

| Each thickness | 40-60 Micron | |||||||

| Spray Pressure | RP Gravity Feed1.2-1.4mm 2.0-2.5 bar HVLP Gravity Feed 1.2-1.4mm 2.0 bar | |||||||

| Drying Time | Temperature | Dust Free | Dry to Handle | Thorough Dry | ||||

| 24 hours@20 0C | 30minutes | 10hours | 1day | |||||

| 1 hours@600C | 15minutes | 1hours | 1hour | |||||

| Sandability and Polishability | wet sanding P800 P1000 sand paper if need polish. | |||||||

| Shelf Life | 3 years in original sealed | |||||||

| Package | 1LX12tins/ctn、4LX4tins/ctn | |||||||

| 1.Remains of water in the sanding marks is harmful to the property of paint film. If the substrate is prepared with P800-P1000 wet, blow dry the surface with spary gun. | ||||||||

| 2.At temperature lower than 15℃, air-dry at ambient temperature is not recommended. Allow a full bake at 60℃. | ||||||||

| 3.At ambient temperature higher than 30℃, add Retarder Solvent into thinner to avoid blushing.

Details please refer to the technical data sheet of Retarder Solvent. |

||||||||

| 4.In the event of fisheyes during application, add 0.5-1% Anti Silicon in the paint remained and

re-spray the affected area. |

||||||||

| 5.In the overspray area of new and existing finish, apply directly Thinner SRA to achieve an invisible transition.

Details please refer to the technical data sheet of Thinner SRA. |

||||||||

| 6.The products mixed with hardener should be used up soon and can not restore for future use. | ||||||||

| 7.Clean equipments immediately with solvent after application. | ||||||||

| 1K Basecoat Colors A,S,P | ||||||||

| Characteristic: Made from weathering resistant resins,the high quality basecoat is with good hiding power,excellent metallic effect and easy to apply.Fast drying single component metallic basecoat for refinishing or general purpose automobiles with excellent metallic effect and easy to apply.

Available in solid, silver and pearl colors. |

||||||||

| Substrates | Dried and sanded existing finishes, primers | |||||||

| Substrates Treatment | Remove paint dust and contaminations with degreaser before sanded | |||||||

| Mixing Ratio | Temperature | Name | 1K Basecoat Color | Thinner | ||||

| According to temperature to choose the Hardener and Thinner | Volume Ratio | 1part | 1-1.2part | |||||

| Remarks | At high temperature,it is recommended to use slow thinner or add proper retarder solvent to avoid mottling. | |||||||

| Pot Life | 24 hours at 20℃ | |||||||

| Spray viscosity | 16-22 Minutes at 20℃ | |||||||

| No. of Coats | 2-3 coats, total 15-25um | |||||||

| Flash-off time | At 25℃, 5-10 minutes between coats. Allow 15-20 minutes air-drying time before applying clear coat. | |||||||

| Each thickness | 10-20Micron | |||||||

| Spray Pressure | Gravity Feed 1.2-1.5mm 2-4kg/cm2 Siphon Feed 1.4-1.7mm 2-4kg/cm2 | |||||||

| Drying Time | Temperature | Dust | application time of next process | |||||

| 200C | 5 minutes | 10-15mintutes | ||||||

| Sandability and Polishability | Use over P1000 sand paper if need polish | |||||||

| Shelf Life | 3 years in original sealed (can continue to use after passing inspection ) | |||||||

| Packaging | 1LX12tins/ctn、4LX4tins/ctn | |||||||

Member Information

| Guangzhou Rapicoat Refinish Technology Co.Ltd,. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 78487953 |

| Contact: | ruby (export manager) |

| Last Online: | 31 Mar, 2020 |

Related Products of this Company

-

1k spot primer surfacer body filler nc

US $2.45

-

two pack epoxy primer with strong

US $2.45

-

car refinishing coats automotive spray

US $5.65

-

MS Clearcoat Standard with properties of

US $3.12

-

2K Primer Surfacer excellent filling

US $5.65

-

Easy to apply unsaturated polyurethane

US $5.35

-

standard automotive clearcoat high film

US $3.26

-

1k crystal auto color basecoat repair

US $5.05

-

2k topcoat-pure solid color tinters

US $5.15