| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | Hardware mould , Plastic mold , Die casting mold |

| Price: |

-

|

| Min. Order: | - |

Product Description

With a continuous die ring, the golden million U.S. dollar!

1. Continuous mold material belt function:

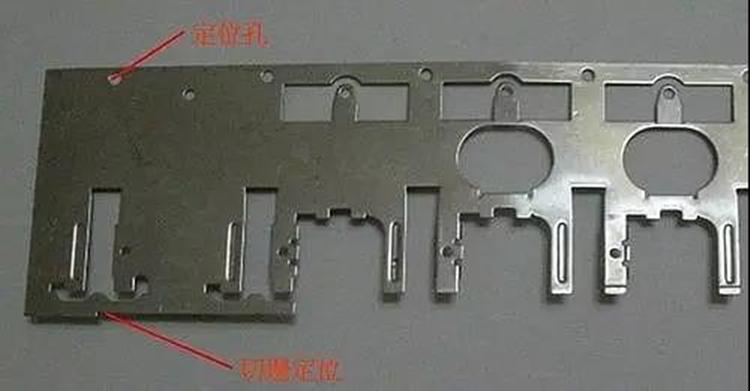

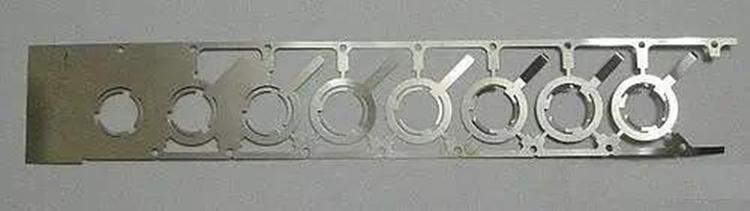

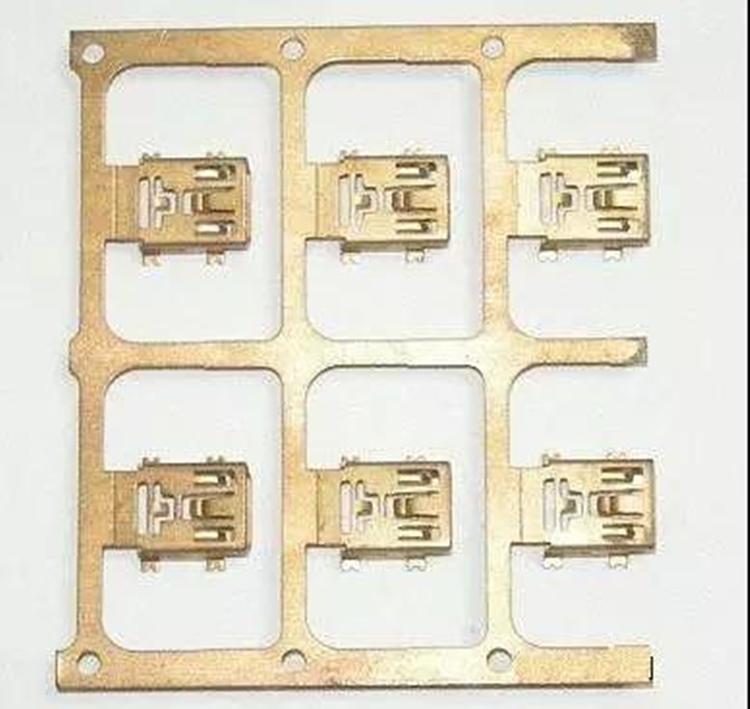

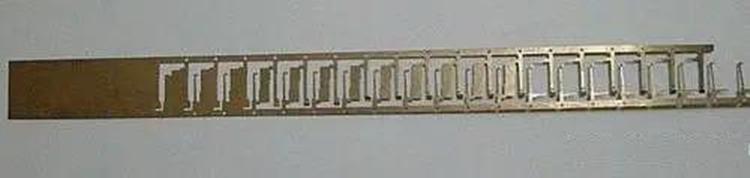

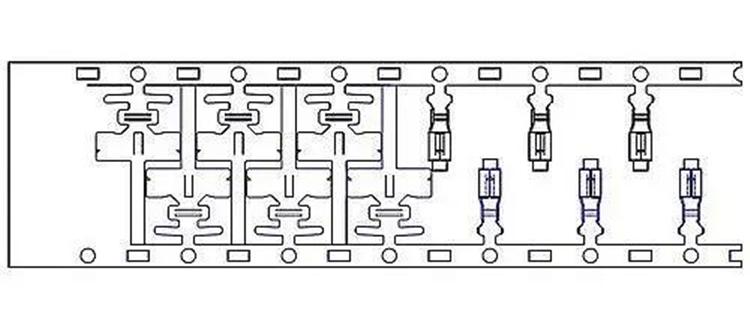

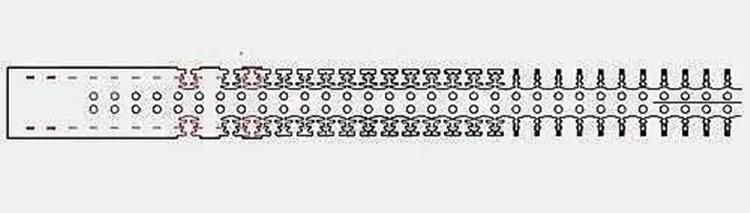

The continuous mold is to arrange the stamping process (station) required to complete the product in the same set of molds for punching. The material used in the continuous mold is coil material, and the material is sent to each separate engineering station in the mold at an equal distance by the feeder for stamping processing, and the product is completed at the final engineering station. In the continuous mold, the materials are processed in stages: punching, separating, bending, etc., and the remaining materials that link the semi-finished products of each engineering station are called strips. Generally, the part that takes the material in the mold and connects the semi-finished products to the finished products of various engineering stations is collectively called the material belt. Experienced mold designers can know the design of this set of molds by observing a material belt.

2. Continuous mold material belt composition:

The material belt is composed of a positioning hole and a safe width of material. The main function of the positioning hole is to allow the material to be sent to each engineering station at an equal distance for stamping processing to ensure the accuracy of stamping processing. The remaining material in the edge width is mainly used as Link and transfer the semi-finished products of each engineering station, link each semi-finished product and send it to the next engineering station for stamping processing.

1. Positioning hole ∮ diameter:

The ∮ diameter of the positioning hole is determined according to the feeding distance (pitch) and the width of the material belt. Generally, it is designed to be ∮ 1.5mm or more, and most of them use 0.5mm as the base as the positioning hole selection method (for example: ∮2.0mm, ∮2.5mm , ∮3.0mm... etc.), but nowadays, stamping parts are getting smaller and smaller, and the feeding pitch is getting smaller and smaller. The existing positioning holes have been set to ∮0.7mm,

2. The width of the material strip setting:

The width of the material belt is mainly to stably connect and transfer the semi-finished products to the stamping engineering station. Generally, the width of the common material belt is set ≧3.0mm, and it can also be designed according to actual needs.

3. Continuous mold material and strip material method:

1. Single-sided tape type:

2. Double-sided tape type:

2. Double-sided tape type:

3. Double material belt type:

4. Double independent material belt type:

5. Intermediate strip type:

4. Application of various continuous die strip materials:

1. Single-sided tape type:

Widely used in connector terminals and smaller stamping parts.

2. Double-sided tape type:

It is mainly suitable for larger stamping parts with complex features, high bending height, wide material width, and easy to deform during the belt conveying process. It cannot be conveyed by a single-sided belt. You can choose double-sided belts. formula.

3. Double material belt type:

The double-belt type is mainly derived from the double-sided belt type. The purpose is also to save material. When double-sided belts are used, two side belts are required for belting. For example, a side-by-side belt is added. It can save a strip of material. This design can also produce different stamping products, but the stamping products need to have the same quantity required at the same time. This is not the case when arranging the same stamping products.

4. Double independent material belt type:

The dual independent material belts are generally designed to save materials. The two stamping products are arranged in opposite directions to achieve the purpose of saving materials. It is also possible to stamp two different stamping products on each side at the same time. For example, when stamping different products, the stamping products must have the same quantity required at the same time. This is not the case when arranging the same stamping products.

5. Intermediate strip type:

It is mainly suitable for products with lower size requirements and lower stamping accuracy. The use of this design method generally improves the material utilization rate, but the relative stamping accuracy and stamping speed are relatively poor, and it is generally not recommended to use this model design.

Member Information

| Huizhou Shunqiang Electronics Co., Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13715334662 |

| Contact: | Kennethchui (Engineer) |

| Last Online: | 31 Jan, 2025 |