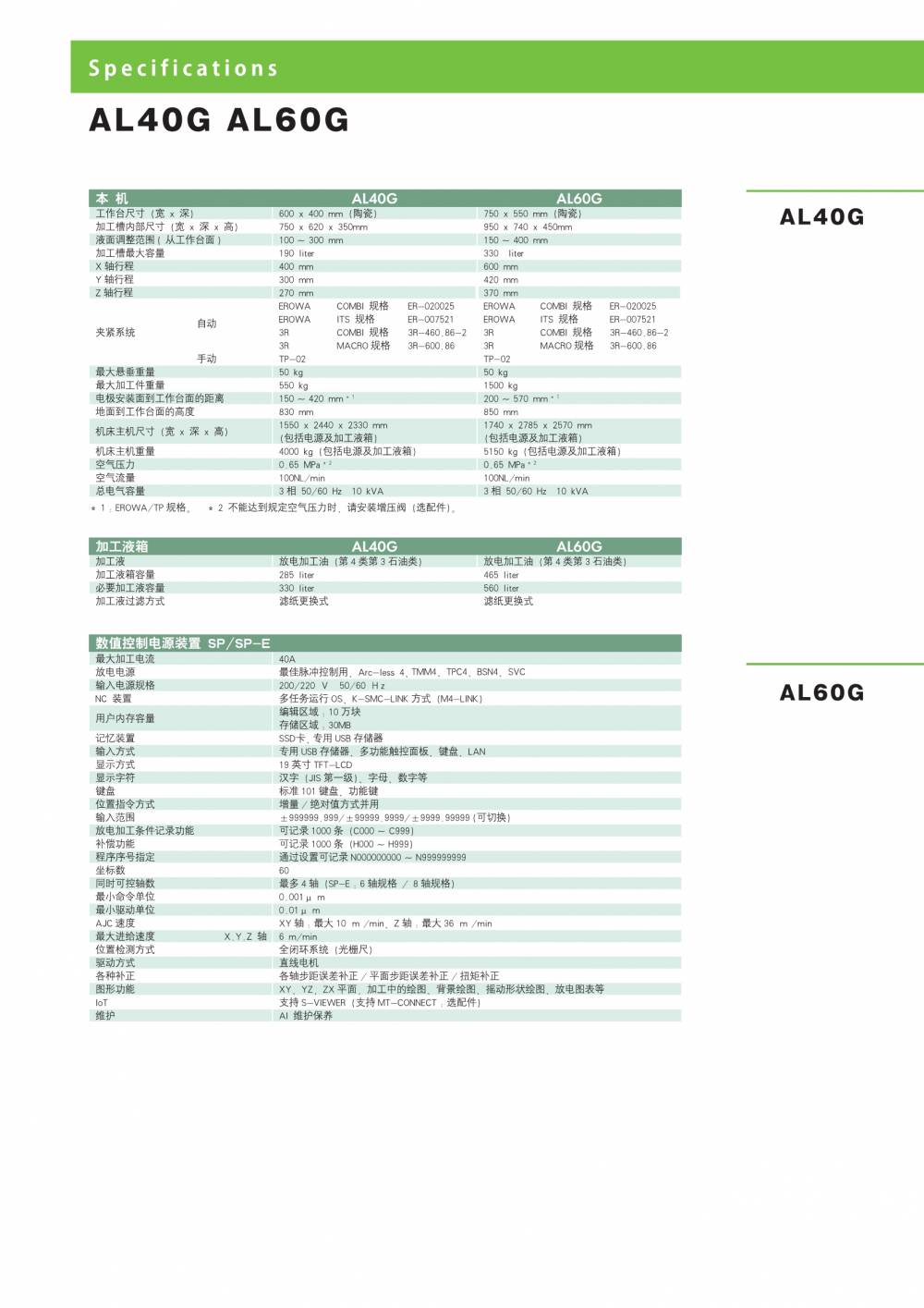

| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In Japan |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | ALN400G_600G , AL40Gs-AL60Gs , ALN400Qs-ALN600Qs |

| Price: |

-

|

| Min. Order: | - |

Product Description

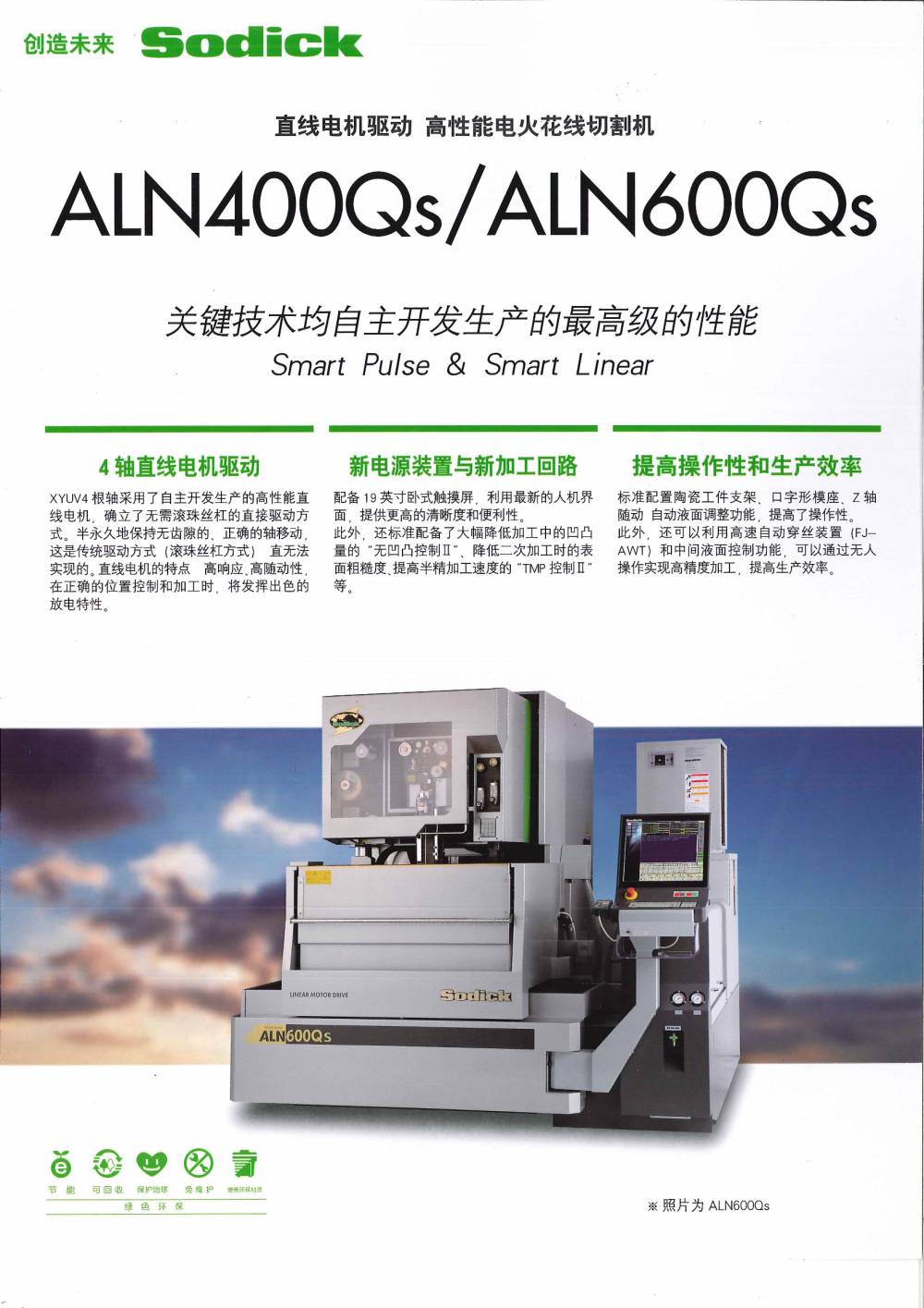

Sodick Wire Cutting AL400G

The ambient temperature will affect the accuracy of the machine tool, a constant temperature working environment is very necessary (installation of air conditioners)

)

The impact of vibration on electrical processing is fatal, and the work site needs to be far away from the source of the earthquake or take measures such as anti-vibration trenches;

Water, electricity and gas are indispensable; pure water, power supply with voltage regulation, and gas source for oil-water separation;

It is recommended to prepare some commonly used consumables, such as electrode wires, conductive blocks, filters, resins, water caps, etc.;

AL400G

AL400G Sodick Wire-feeding Machine Specifications (Sodick)

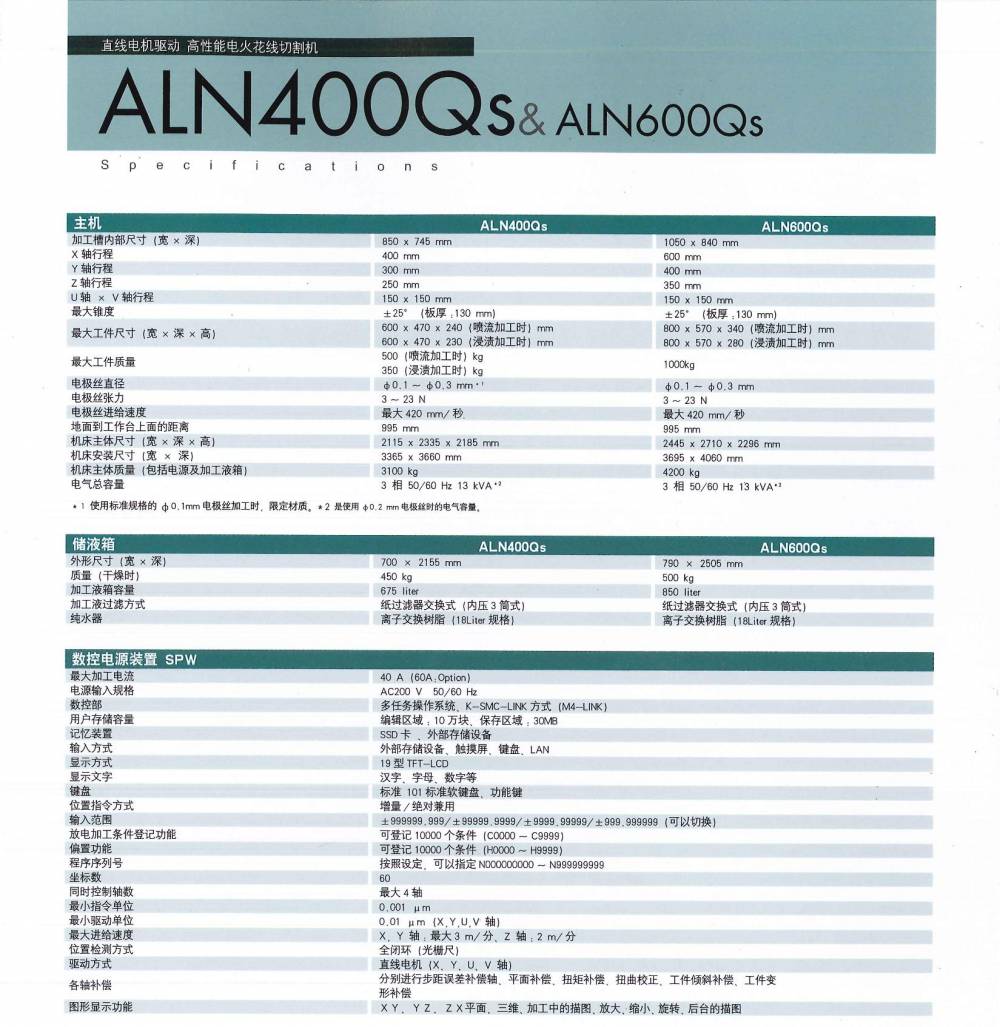

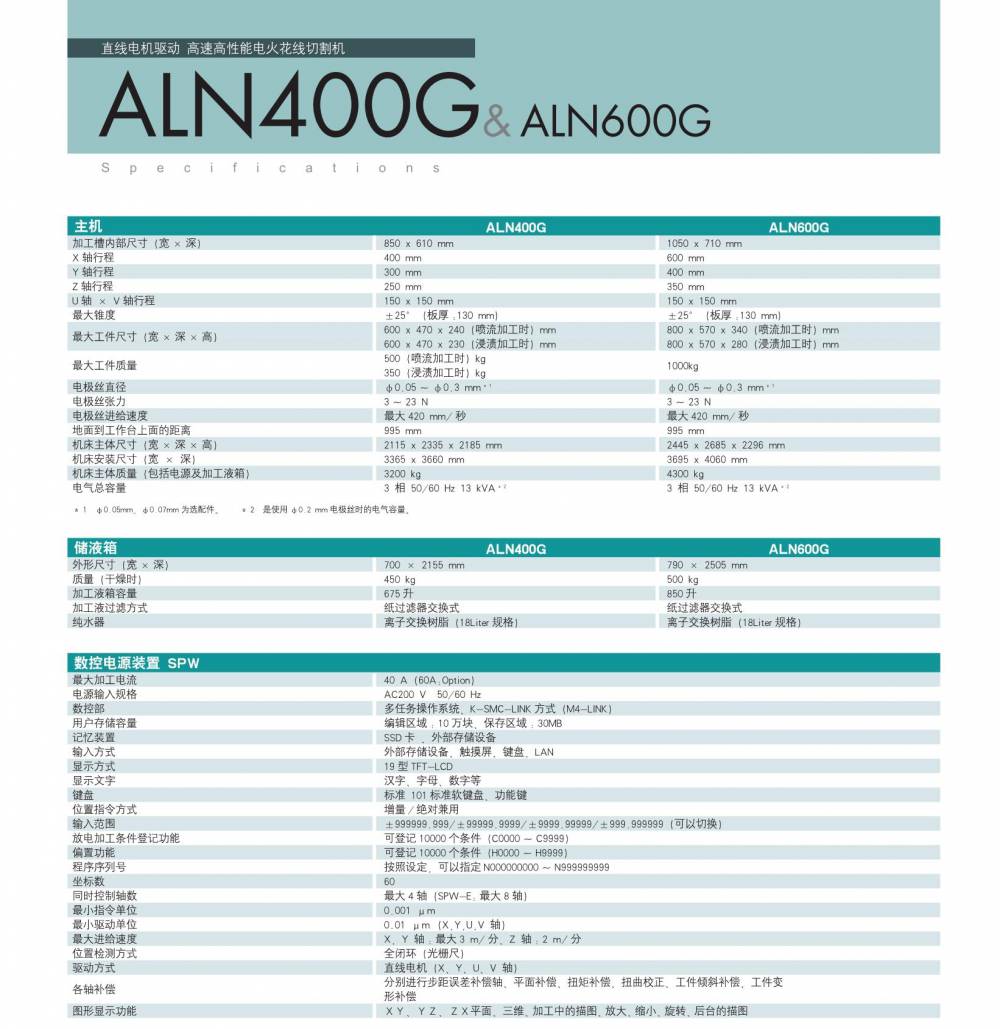

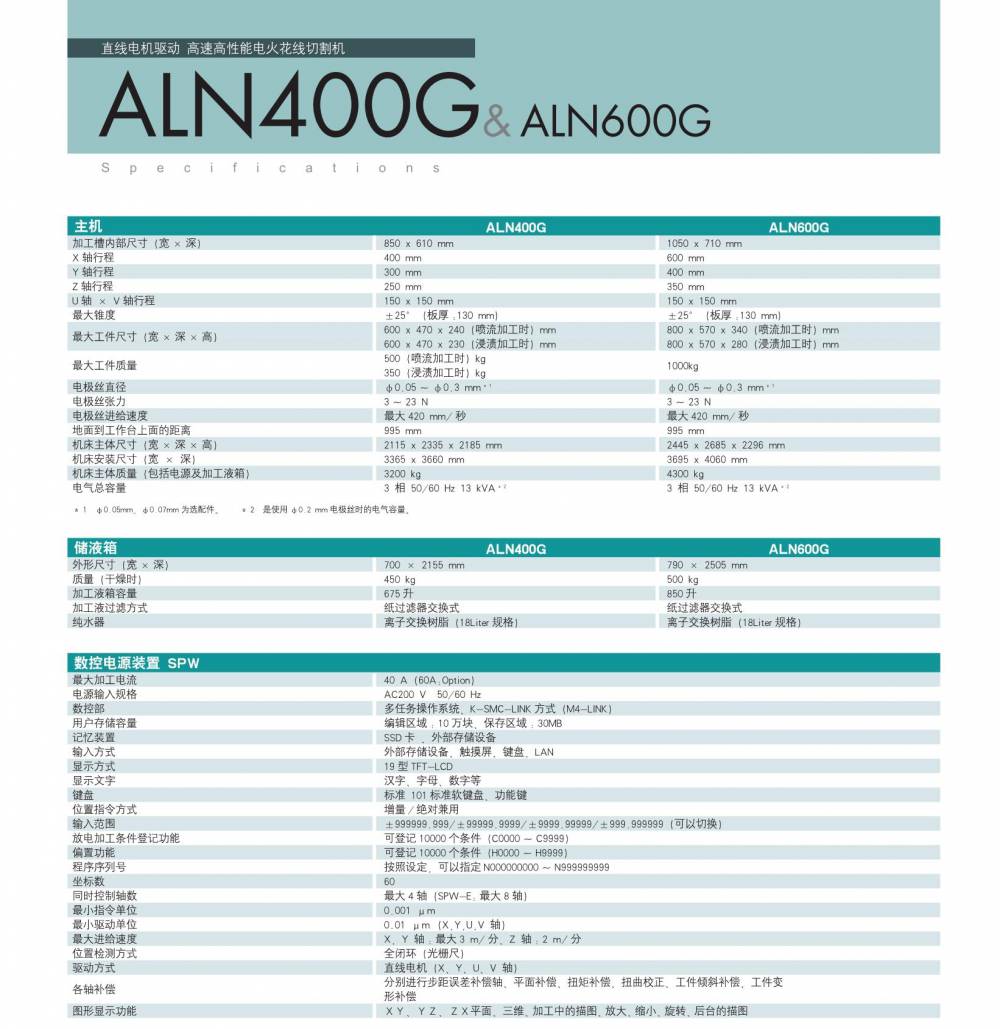

X, Y, Z stroke

400mm*300mm*250mm

U, V stroke

150mm*150mm

Taper machining control angle

±25° (plate thickness: 130mm)

Workpiece size (immersed in water)

600mm*470mm*240mm

Workpiece size (water spray)

600mm*470mm*230mm

Quality of processed material

500KG (water immersion), 350KG (water spray)

AL400G electrode wire diameter

0.1mm - 0.3mm

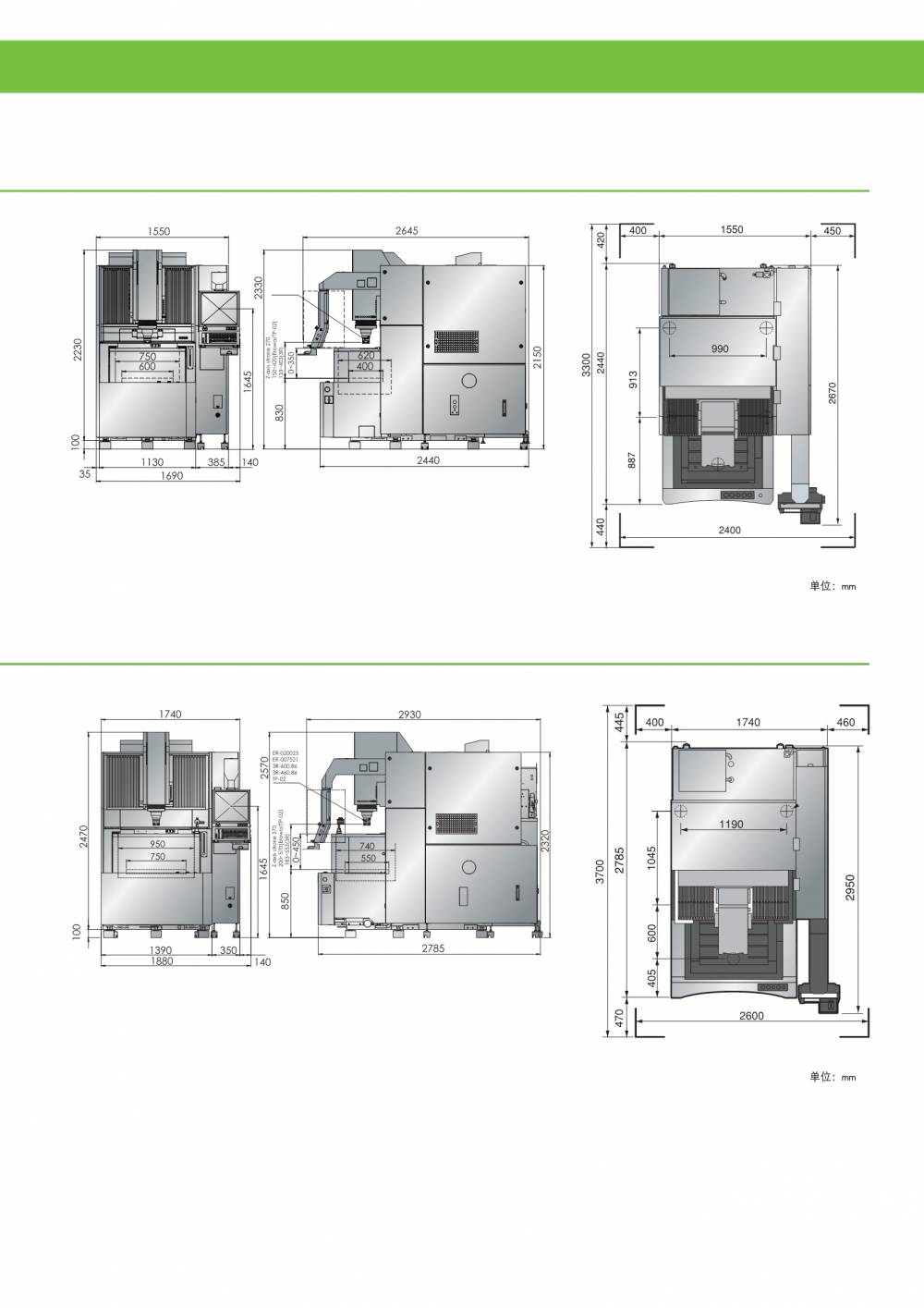

AL400G machine body size

2115mm*2500mm*2230mm

AL400G

AL400G Sodick Wire Cutting Power Supply Unit Instructions (Sodick)

Machining current

40A (optional 60A)

power input

380V (system power 220V)

CNC device

Multitasking operating system, K - SMC - LINK mode (M 4 - LINK)

memory device

SSD, external storage

Input

External memory, multi-touch screen, on-screen keyboard, local area network

Display method

Type 19 TFT

display text

Chinese characters (JIS), letters, numbers, etc.

keyboard

Standard 101 reference keyboard, function keys

position command method

Incremental coordinates, coordinates

EDM condition registration function

10000 conditions can be registered (C000-C9999)

Compensation function

10000 conditions can be registered (H000-H9999)

Program sequence number specification

Setting ratio N 000000000-N 999999999 possible

number of coordinates

60

Simultaneous control of the number of axes

4 axes (SPW - E: 8 axes)

Minimum instruction unit

0.001um

Minimum drive unit

0.01um (X, Y, U, V) axis

Transmission speed

X, Y axis 3m/min; Z axis 2m/min

position detection system

Fully closed loop control (optical ruler)

Drive System

Linear motor (X, Y, U, V axis)

various compensation

Each axis step gauge error compensation, clearance compensation, torque compensation

Graphics function

Plane, drawing during processing, 3D, enlargement, reduction, rotation, background drawing

AL400G

AL400G Sodick slow-moving wire characteristics description (Sodick)

Four-axis linear motor device

X, Y, U, V are equipped with linear motors, and Sodick's patented cooling form;

Improve operability and productivity

Standard configuration ceramic workpiece support, mouth-shaped die base, automatic three-side up and down type processing tank, Z-axis follow-up

The automatic liquid level adjustment function improves the operability. In addition, high-speed automatic threading device can also be used

And the intermediate liquid level control function can realize high-precision processing through unmanned operation and improve production efficiency.

New power supply unit and new processing circuit

It integrates the tablet mode and the traditional mode, which is the first in the world, and makes the SPW of the CNC device further

upgrade. It is also equipped as standard with No-Bump Control II, which greatly reduces the amount of bumps during machining, and reduces secondary stress.

The surface roughness of the working hours, the improvement of the semi-finishing speed, etc.

Fully closed control

The world's four-axis HEIDENHAIN optical ruler (0.01um)

Automatic threading device

Realize high reliability automatic fusing and automatic wire threading (AWT)

Processing fluid temperature constant device

It can keep the temperature of the processing fluid stable and meet the requirements of high-precision cutting;

Processing liquid level automatic adjustment device

Through the automatic adjustment of the liquid level, unmanned operation can be realized (water spraying or water immersion can be used)

workbench

The original "C-shaped" workbench was changed to a ceramic "mouth-shaped" workbench;

UTY editing system

Through this system, operation program editing can be realized on the machine;

0.1 wire diameter cutting power supply

Equipped with a power supply that can be used for 0.1 wire diameter cutting to achieve smaller R angle processing;

TK2

The amount of deformation during processing is greatly reduced, depending on the application of the "TK2" feedback control circuit;

touch operation

ALN series wire cutting world is the first to be equipped with a touch panel computer operation mode;

Liquid level tracking function

Standard configuration Z-axis tracking liquid level tracking function, this solution can improve operability;

unmanned operation

Rely on high-speed automatic wiring device and liquid level tracking adjustment function to improve work efficiency;

self-developed

ALM series element technology is developed and manufactured by Sodick to exert its performance;

AL400G

| Embed HTML Code: | |

|---|---|

Member Information

| Wyldar Group | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Trading Company |

| Phone: | 13631719363 |

| Contact: | Mr. Lee (Sales) |

| Last Online: | 26 Sep, 2024 |

Related Products of this Company

-

CHevalIER SMART-B818III New Energy

-

CHevalIER Moving beam gantry grinder

-

Taiwan Fuyu Vertical Lathe FVL-8 12 20

-

Rs ultrasonic spindle focuses on hard

-

Taiwan CHEVALIER FVGC-40/50/60/63/U60

-

CHEVALIER Manual grinder FSG-618M

-

Japan Mitsui grinder chn original

-

CHevalIER Double end surface grinder

-

CHevalIER SMART-HB 1224 1640III

-

CHevalIER FSG-H818CNC FSG-B818CNC