| Model: | HGM |

|---|---|

| Brand: | SBM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | industrial mill , grinding mill , powder grinder |

| Price: |

US $78000

/ set

|

| Min. Order: | 1 set |

Product Description

Discharge fineness: 325-3000 mesh

Feed size.: <25 mm

Output: 0.5-45 t/h

BRIEF INTRODUCTION OF ULTRA FINE POWDER MILL

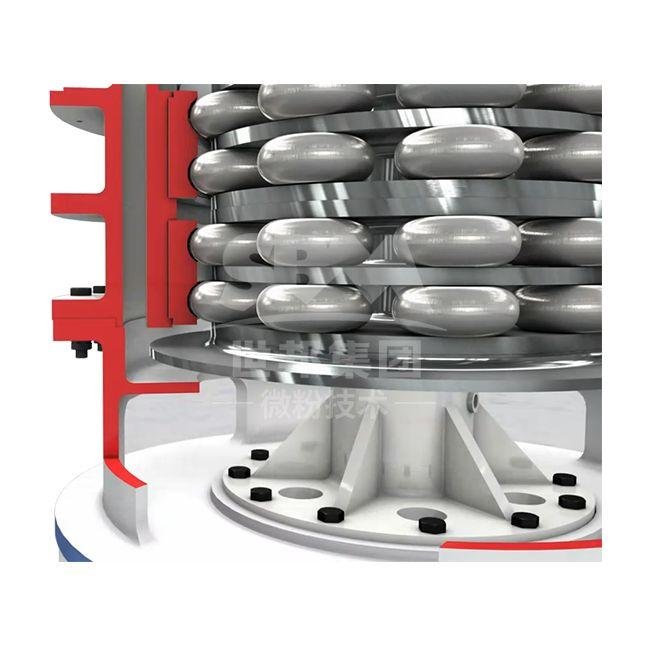

HGM series ultrafine powder mill (three-ring / four-ring medium-speed micro-powder mill) is a high-efficiency and low-consumption ultra-fine powder processing equipment that successfully replaces the traditional jet mill and complex process ball mill grinding and powder selection, greatly reducing production costs. Improve the fineness of the product.

Thousands of domestic users have proved that this equipment has the advantages of superior performance, stable quality, simple operation, and convenient maintenance. It is a piece of ideal equipment for ultrafine powder processing.

FEATURES OF ULTRA FINE POWDER MILL

- It can be adjusted arbitrarily to produce a finished powder with a fineness of 325 meshes to 2500 meshes.

- It is suitable for grinding hundreds of materials with Mohs hardness below 6.

- The equipment investment is small, and the operation is simple.

- The equipment can operate continuously for 24 hours.

APPLICATIONS OF ULTRA FINE POWDER MILL

An ultrafine powder mill is suitable for processing non-flammable and explosive brittle materials with medium and low hardness.

It can grind and process many materials such as calcium carbonate, kaolin, bentonite, talc, mica, attapulgite, barite, gypsum, graphite, etc.

Its applications have spread across many industries such as paint, papermaking, pigments, rubber, plastics, fillers, cosmetics, chemical supplies, etc.

WORKING PRINCIPLE OF ULTRA FINE POWDER MILL

After the large pieces of material are crushed to the required size by the jaw crusher, the material is sent to the storage hopper by elevator.

And then sent to the main grinding chamber evenly and continuously by the vibrating feeder for grinding. The ground powder is taken away by the airflow of the fan and classified by the analyzer.

The finished product that meets the fineness is collected by the airflow through the pipe, then into the large selection air collecting pipe. And then discharged through the powder outlet pipe to become the finished powder.

ADVANTAGES OF ULTRA FINE POWDER MILL

1. The yield is 40% higher than other mills.

2. High utilization rate of Wear material: 2-5years.

3. Adjustable particle size: 325-3000 mesh.

4. High safety and reliability: The design of the mill is rigorous, so no screw loosening to damage the machine.

5. Closed system, so it is the green and ideal equipment for environment protection.

6. Environment-friendly: The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

PARAMETER OF ULTRA FINE POWDER MILL

| Parameters of HGM series ultrafine mill | |||||||

|---|---|---|---|---|---|---|---|

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 |

315 |

Welcome to visit our website https://www.sbmmill.net to get more about industrial powder grinding mill. If you are interested in our ultrafine powder grinding mill, please feel free to contact us: Email info@sbmwfjs.cn ; WhatsApp +86 18917951321

| Payment Terms: | T/T, L/C, Western Union |

|---|---|

| Embed HTML Code: | |

Member Information

| Shanghai CLIRIK Machinery Co.,Ltd | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 18917951321 |

| Contact: | LI (Staff) |

| Last Online: | 26 Sep, 2021 |

Related Products of this Company

-

industrial ore grinding machine

US $78000

-

Ultrafine Vertical Mill

US $589999

-

superfine verticla roller mill for ore

US $589999

-

Industrial superfine powder mill machine

US $78000

-

Coarse Powder Grinding Mill

US $20000

-

Raymond Grinding Roller Mill

US $24000

-

Micro Powder Grinding Mill

US $78000

-

Ultra Fine Wet Stirring Mill

US $300000

-

Powder Surface Coating Machine

US $9000

-

Raymond mill; Raymond powder grinder

US $24000