| Model: | YGM |

|---|---|

| Brand: | SBM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | Raymond mill , grinding mill , powder mill |

| Price: |

US $24000

/ set

|

| Min. Order: | 1 set |

Product Description

Raymond Grinding Roller Mill

Feed size of Raymond roller mill: 0-30 mm;

Finished product size: 50-500 mesh;

Raw Material: Feldspar, calcite, limestone, talc, barite, rare earth, marble, phosphate ore, kaolin, bentonite, gypsum etc.

Raymond roller mill is mainly used in small and medium-sized mines, chemicals, building materials, metallurgy, pharmaceuticals, cement, etc., which provides great help for the processing of different materials in these industries.

Raymond mill is a new type of powder mill instead of ball mill for processing powder, which is more efficient than ball mills, has lower power consumption, smaller floor space, and less one-time investment.

Application of Raymond grinding roller mill:

Capacity: 1-30 t/h

Input size: 0-30 mm

Final product size: 50-500 mesh

SBM Raymond mill can be used to grind non-flammable and explosive minerals with Mohs hardness below 9.3 and humidity less than 6%, including quartz, talc, marble, limestone, dolomite, lime, activated clay, activated carbon, bentonite, kaolin, Cement, phosphate rock, gypsum, graphite, glass, manganese ore, titanium ore, copper ore, chrome ore, refractory materials, insulation materials, clay, titanium dioxide, iron oxide, etc.It can complete the processing of ultra-fine powder of more than 300 materials in the construction, chemical, fertilizer and other industries.

Structural characteristics of Raymond grinding roller mill:

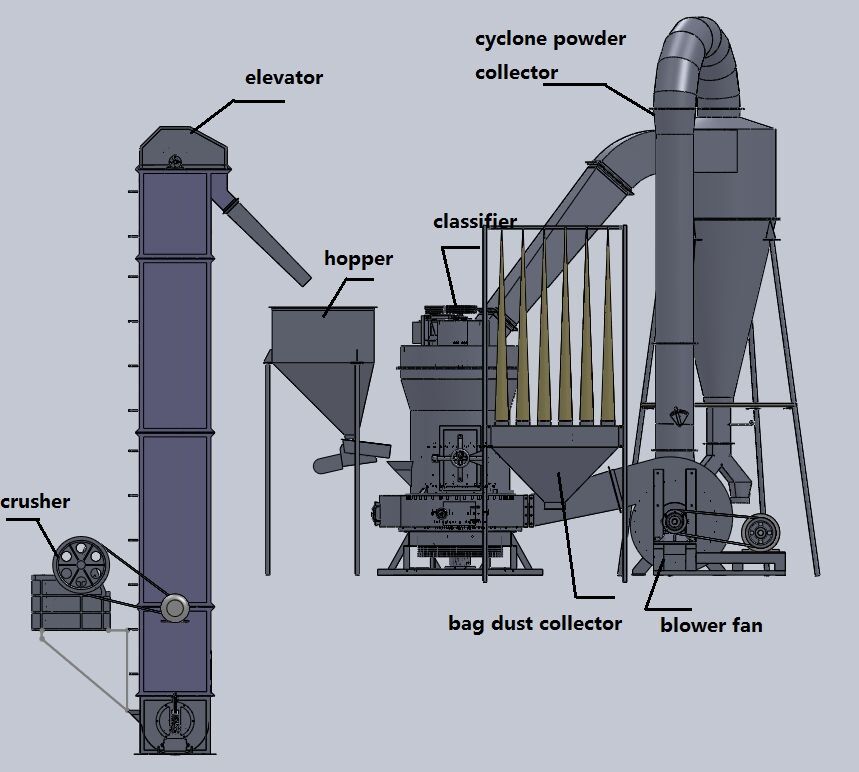

Raymond mill powder is mainly composed of a host, an analyzer machine, a fan, a finished cyclone separator, a fine powder cyclone separator and a wind pipe.

1. The Raymond mill has a three-dimensional structure, small footprint, and strong complete set. It forms an independent production system from block material to finished powder.

2. The fineness of the finished powder is uniform, and the sieving rate is 99%, which is difficult for other milling equipment to have.

3. The transmission device of the main machine of the pulverizer adopts a closed gear box and belt wheel, which is stable in transmission and reliable in operation.

4. The important parts of Raymond Mill are made of high-quality steel, and the wear parts are all made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

5. The electrical system adopts centralized control, the grinding workshop can basically realize unmanned operation, and the maintenance is convenient.

Working Principle of Raymond grinding roller mill:

The raw materials are first crushed to the required size by the jaw crusher, and the materials are sent to the hopper by the elevator, and then enter the main machine through a continuous, uniform and quantitative vibrating feeder for crushing.

Grinding process: When working, the material to be crushed is fed into the machine from the feed hopper on the side of the main machine casing, and the grinding roller device suspended on the plum blossom frame of the main machine revolves around the vertical axis and rotates itself at the same time. Due to the centrifugal force during rotation, the grinding roller swings outwards and tightly presses on the grinding ring, so that the shovel blade scoops up the material to be sent between the grinding roller and the grinding ring, and the grinding roller is rolled and crushed to achieve the purpose of crushing the material.

Wind separation process: After the material is ground, the fan blows the wind into the main casing, blows up the powder, and is sorted by the analyzer above the grinding chamber. The material that meets the requirements of fineness passes through the analyzer, and cannot meet the requirements. The grinding cavity continues to grind, and the material passing through the analyzer enters the cyclone separator for separation and collection, and finally is discharged through the powder outlet tube, which is the finished product.

Advantages of Raymond grinding roller mill:

1. Under the sufficient grind force, reduced the roller and increased the grind space, The material layer filled better between the roller and ring, the attrition between rollers and rings is low, and the vibration and noise are also reduced, at the same time, the resistance of airflow of the fan becomes less. Winds can flow freely, thus the winds increase greatly, which determines the increase in the production volume. The production volume is 20% to 30% higher than R Raymond mill.

2. The increase mechanism of linkage pressure of the rollers, which greatly prolongs the useful life of the equipment and increases the capacity by 20% under the same power.

3. With the original roller assembly, the oiling time increased 6-15 times, archive the application of oil once, use for 30-45 days.

4. High efficiency and stability, the ring and roller always contact during processing, the efficiency and stability of the grind are improved.

5. Higher Accuracy powder Classify, without coarseness missing, Variable frequency Squirrel cage classifier(Patent product) is adopted, the accuracy is 80-600 meshes.

Welcome to visit our website https://www.sbmmill.net to get more about industrial powder grinding mill. If you are interested in our ultrafine powder grinding mill, please feel free to contact us: Email info@sbmwfjs.cn ; WhatsApp +86 18917951321

| Payment Terms: | T/T, L/C, Western Union |

|---|---|

| Embed HTML Code: | |

Member Information

| Shanghai CLIRIK Machinery Co.,Ltd | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 18917951321 |

| Contact: | LI (Staff) |

| Last Online: | 26 Sep, 2021 |

Related Products of this Company

-

Ultrafine Vertical Mill

US $589999

-

Vertical Roller Mill

US $589999

-

Ultra Fine Wet Stirring Mill

US $300000

-

Micro Powder Grinding Mill

US $78000

-

industrial ore grinding machine

US $78000

-

Stone Powder Making Machine

US $78000

-

Industrial superfine powder mill machine

US $78000

-

Coarse Powder Grinding Mill

US $20000

-

Raymond mill; Raymond powder grinder

US $24000

-

Ultra Fine Grinding Mill

US $78000