| Model: | CLUM |

|---|---|

| Brand: | SBM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | vertical mill , vertical roller mill , grinding mill |

| Price: |

US $589999

/ SET

|

| Min. Order: | 1 SET |

Product Description

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 1-20 T/H

BRIEF INTRODUCTION OF VERTICAL ROLLER MILL

CLUM Vertical roller mill is a new type of milling equipment that includes grinding, grading, conveying, secondary powder selection, and finished product packaging.

It is a large-capacity ultra-fine grinding and separation equipment developed by SBM, based on its 30 years of research and operation experience in the grinding industry.

CLUM Vertical roller mill is suitable for the production of fillers and coating calcium carbonate in large paper mills and the processing of other large-volume ultra-fine powders.

APPLICATIONS OF VERTICAL ROLLER MILL

Vertical roller mills are widely used in chemical, metallurgy, non-metallic mining, and other industries. It suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 7(the Moh’s hardness). Such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

FEATURES OF VERTICAL ROLLER MILL

1 High production capacity

2 Advanced control system

3 Special wearable alloy materials

4 Strong drying capacity: drying and grinding raw materials with a moisture content of up to 15%.

5 Environmental protection

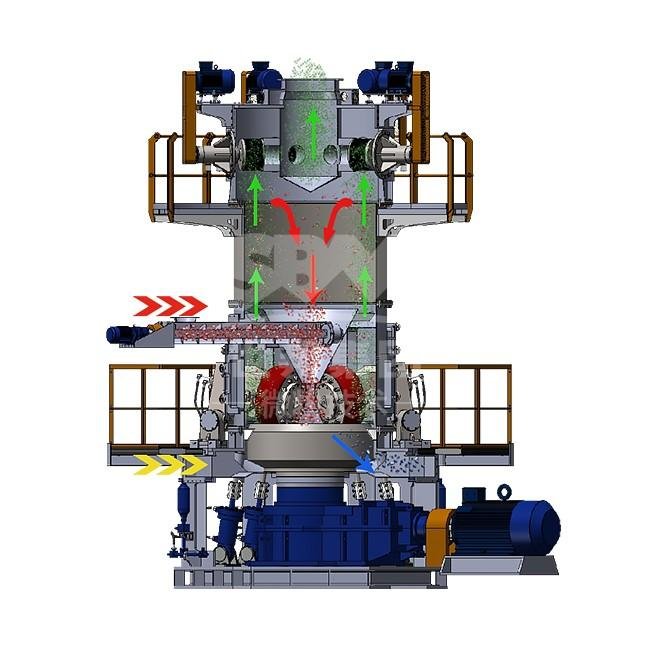

VERTICAL ROLLER MILL WORKING PRINCIPLE

The grinding wheel is driven by a motor through a reducer. The material is fed into the main machine of the vertical roller mill through the feed screw and falls into the center of the grinding disc.

Under the action of centrifugal force, the material spreads from the center of the grinding disc to the surroundings and is rolled into fine powder.

The powdery material continues to move to the edge of the grinding disc until it is taken away by the strong airflow from the air inlet and enters the high-efficiency classifier. The qualified dust is collected by the integrator, and the unqualified dust is sent back for regrinding.

ADVANTAGES OF VERTICAL ROLLER MILL

1. Good quality of finished products: Finished products have high whiteness, fine particle size, narrow particle size distribution, and good particle sphericity. The fineness D97 of the finished powder can reach 3000 meshes, and the content of 2μm can reach up to 60%.

2. High grinding efficiency: save 20~30% power consumption compared with the ball mill.

3. Strong drying capacity: dry and grind raw materials with moisture content as much as 15%.

4. Multifunction: crushing, drying, grinding, separating, and conveying.

5. Low noises and little dust: no direct contact between the grinding rollers and grinding disc, so metallic impact is avoided, and its noises are 20~25 decibels lower. Totally closed negative pressure operation has been employed by this vertical grinding mill, so there is little dust during the operation.

6. Low wear rate and little metallic pollution: its metal wear is only 5~10g/t.Low wear rate and little metallic pollution: its metal wear is only 5~10g/t.

INDUSTRIAL ULTRAFINE VERTICAL ROLLER MILL CUSTOMER CASE

-calcium carbonate ultrafine powder production line

CLUM series ultrafine vertical roller mills have a large capacity, stable operation, low wear, long life, environmental protection and energy saving, simple operation, intelligent control system, easy maintenance, and the fineness can be freely adjusted between 150-3000 meshes.

The fineness of the calcium carbonate powder produced can reach 3000 meshes. The finished powder has high whiteness, good powder ball shape, high 2um fine powder content, and more fine powder content. It is a high-end powder without iron, especially suitable for high-end coatings, papermaking, and other fields.

Welcome to visit our website https://www.sbmmill.net to get more about industrial powder grinding mill. If you are interested in our ultrafine powder grinding mill, please feel free to contact us: Email info@sbmwfjs.cn ; WhatsApp +86 18917951321

| Payment Terms: | T/T, L/C, Western Union |

|---|---|

| Embed HTML Code: | |

Member Information

| Shanghai CLIRIK Machinery Co.,Ltd | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 18917951321 |

| Contact: | LI (Staff) |

| Last Online: | 26 Sep, 2021 |

Related Products of this Company

-

Raymond Grinding Roller Mill

US $24000

-

Jaw Crusher

US $5000

-

Coarse Powder Grinding Mill

US $20000

-

superfine verticla roller mill for ore

US $589999

-

Ultra Fine Powder Mill

US $78000

-

industrial ore grinding machine

US $78000

-

Ultra Fine Wet Stirring Mill

US $300000

-

Raymond mill; Raymond powder grinder

US $24000

-

Ultra Fine Grinding Mill

US $78000

-

Ultrafine Vertical Mill

US $589999