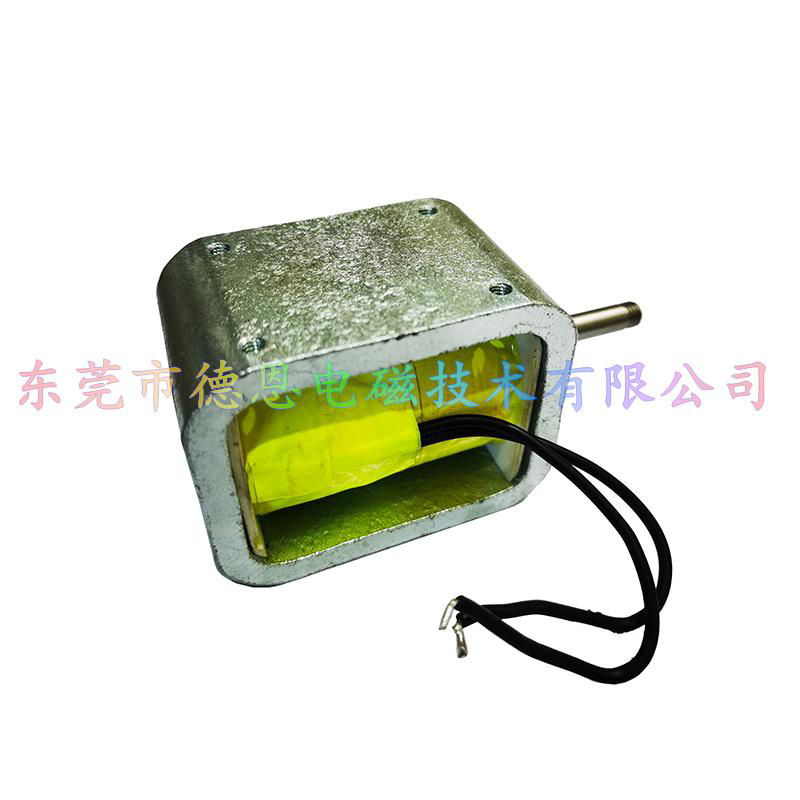

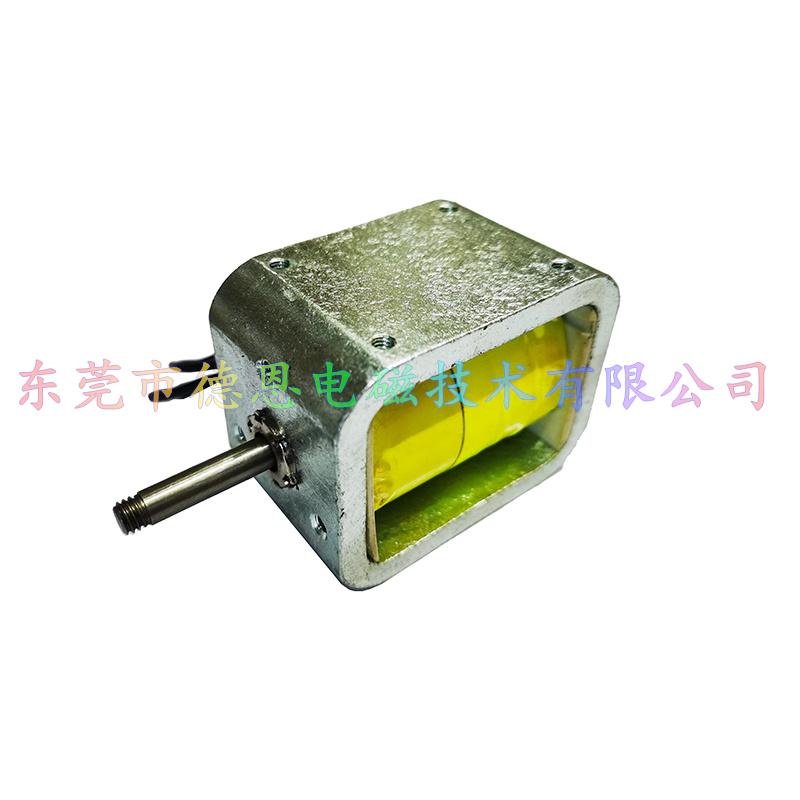

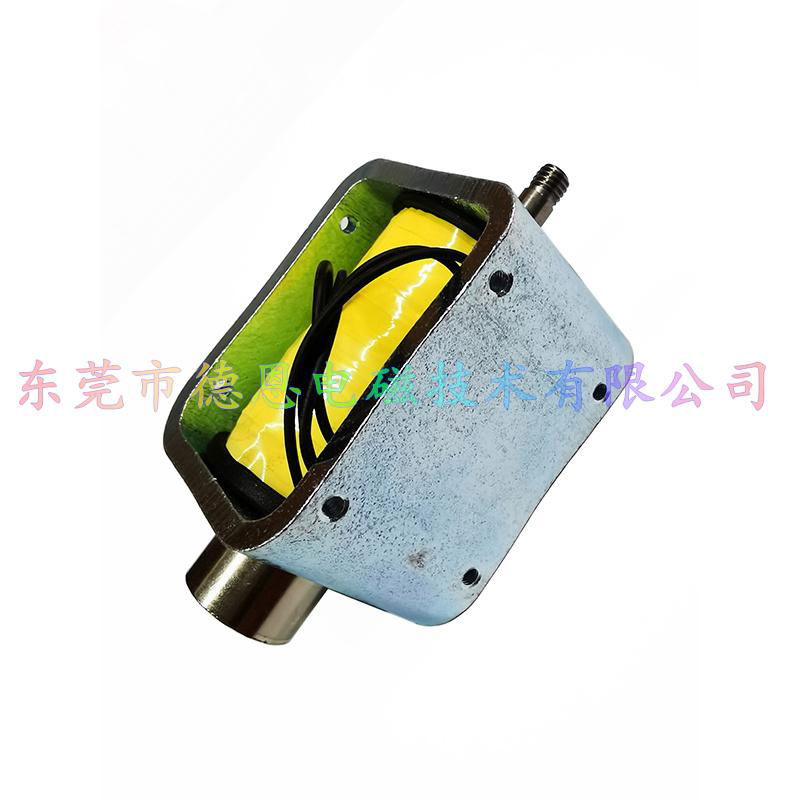

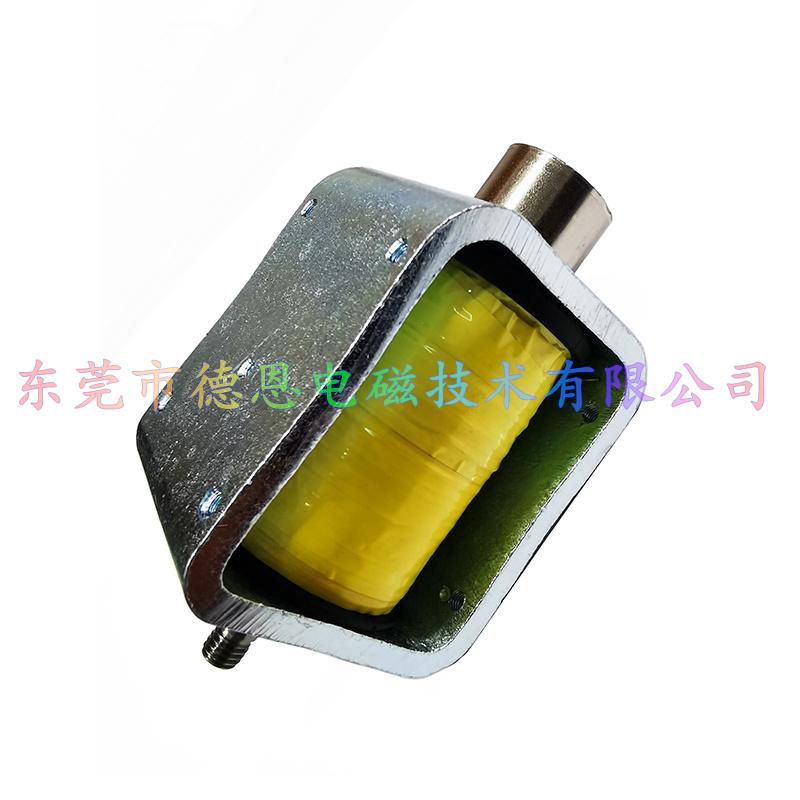

DU2576 high voltage electromagnet, high current and high thrust electromagnet

Frame-shaped design, easy to install the shell, the movable sliding rod can move flexibly after power-on, and can be designed into two types: pull-type and push-type. After the coil is energized, the moving iron core produces axial linear motion, which acts as a push and pull external load device function.

The main frame size is 76mm long; 48mm wide; 60mm high.

Working voltage: AC/DC12-220V

Installation method: 2/4 threaded holes on the side

Working environment temperature: -10℃-180℃

The frame electromagnet is mainly composed of shell, wire rack, copper tube, copper wire, cover plate, sliding rod, ejector rod, stopper, spring and wire terminal.

Solenoid valves can be divided into AC solenoid valves and DC solenoid valves according to the power they use, using AC solenoids and DC solenoids respectively. AC electromagnets and DC electromagnets have different electric and magnetic parameters in the process of holding the electromagnetic coil from power-off to power-on, and the dynamic and static iron cores. For the AC electromagnet, it is "the magnetic flux is constant, the current changes", while for the DC electromagnet, it is "the current remains the same, the magnetic flux changes". The magnitude of the magnetic flux determines the magnitude of the electromagnetic attraction force. The design of the AC and DC electromagnets will therefore be somewhat different. The following only takes the DC solenoid valve as the object, and briefly explains how to enhance the magnetic force of its iron core.

1. When the size of the solenoid valve allows, try to choose an iron core with a larger section. The large-section iron core allows more magnetic flux, and of course it is possible to generate a large electromagnetic attraction;

2. Within the allowable range of the solenoid valve spool stroke, try to reduce the length of the air gap in the iron core. The reluctance in the air is large, reducing the length of the air gap in the iron core can reduce the reluctance of the magnetic circuit, thus making the magnetic force stronger;

3. We know that the size of the magnetic flux in the iron core and the number of turns of the coil are related to the product of the current passing through the coil. We call the product of the number of turns of the coil and the current passing through the coil as the ampere-turn. In the case of a certain iron core, the larger the number of ampere-turns of the coil, the stronger the suction of the iron core. In the determination of the size of the electromagnet In this case, the size of the electromagnetic coil is also limited. In this limited range, in order to obtain the best electromagnetic attraction, the number of turns of the coil and the wire diameter of the coil (this is related to the allowable current) must have a good value. In order to obtain a large number of ampere turns, so in order to achieve this good effect (large electromagnetic attraction), for the determined coil, sometimes it may be necessary to increase the number of turns to reduce the wire diameter, and sometimes it may be necessary to reduce the number of turns to increase wire diameter. In short, the principle of obtaining large ampere turns is the principle, of course, the influence of the power supply voltage connected to the coil on the coil parameters must be considered. Electromagnet manufacturer, large thrust electromagnet