| Model: | - |

|---|---|

| Brand: | Spark |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Alloy |

| Label: | - |

| Price: |

US $20

/ pc

|

| Min. Order: | 10 pc |

Product Description

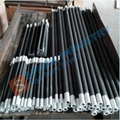

ANTI-OXIDANT PROPERTY OF ELEMENTS:

The silicon carbide heating element is a kind of non-metal high temperature electric heating element. It is made of selected super quality green silicon carbide as main material, which is made into blank, silicided under high temperature and re-crystallized. Compared with metal electric heating element, this kind of element is characterized by high-applied temperature, anti- oxidization, anti- corrosion, long service life, little deformation, easy installation and maintenance. Therefore, it is widely used in various high temperature electric furnaces and other electric heating devices, such as in the industries of magnet, ceramics, powder metallurgy, glass and machinery,etc.

We adopt new production process of cold ends, so our Sic heating elements have excellent specific rate of heat zone resistance and cold end resistance, saving energy, long life, avoiding over-temperature of cold ends to damage the furnace body.

Electric heating elements are a popular choice of many heat treaters. They come in a variety of shapes, sizes and materials. One of the most common types are silicon carbide heating elements. They are used extensively throughout the heat-treating industry when high temperatures, maximum power and heavy-duty cycles are required.

When making an inquiry, please specify the following:

- Outer diameter (OD)

- Length of Hot zone (HZ)

- Cold end length(CZ)

- Length of Overall (OL)

- Vottage and Wattage

- Quantity

Tips for Extended Service Life

To maximize element life, be sure to do the following:

1. Handle the elements with care – Silicon carbide heating elements have low tensile strength and, therefore, are sensitive to mechanical damage from rough handling, dropping (even in the packaging) or forced bending that can occur during storage, unpacking or installation.

2. Match resistance – The purpose of matching resistance of elements is to improve their life and to improve temperature uniformity in the furnace. Silicon carbide heating elements are typically factory tested with the test amperage marked on the shipping box and/or the element. Elements can be connected in parallel (preferred since they tend to come into balance in use), series or series-parallel. Elements connected in parallel should be matched in resistance within ±20%, while elements connected in series should be matched within ±5%.

3. Choose the proper size element for the equipment – If there are any doubts about the size to use, check the design parameters with the original furnace equipment manufacturer.

| Payment Terms: | TT / LC / PayPal |

|---|---|

Member Information

| Spark Industry (Henan) Co., Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15664173999 |

| Contact: | Summer Song (Salesman) |

| Last Online: | 28 Sep, 2022 |

Related Products of this Company

-

Moly Disilicide MoSi2 Heating Element

US $25

-

Annealing Furnace Sic Rod Heating

US $20

-

1900 Degree Molybdenum Disilicide

US $25

-

1800℃ High Purity MoSi2 High Temperature

US $25

-

W ED Type Silicon Carbide Heater High

US $20

-

W Shape Silicon Carbide Heating Element

US $20

-

High Purity MoSi2 High Temperature

US $25

-

High Purity Silicon Carbide Heating

US $20

-

Anti Oxidant SiC Heaters of High

US $20

-

1000-6200W Element Sic Of High

US $20