| Model: | - |

|---|---|

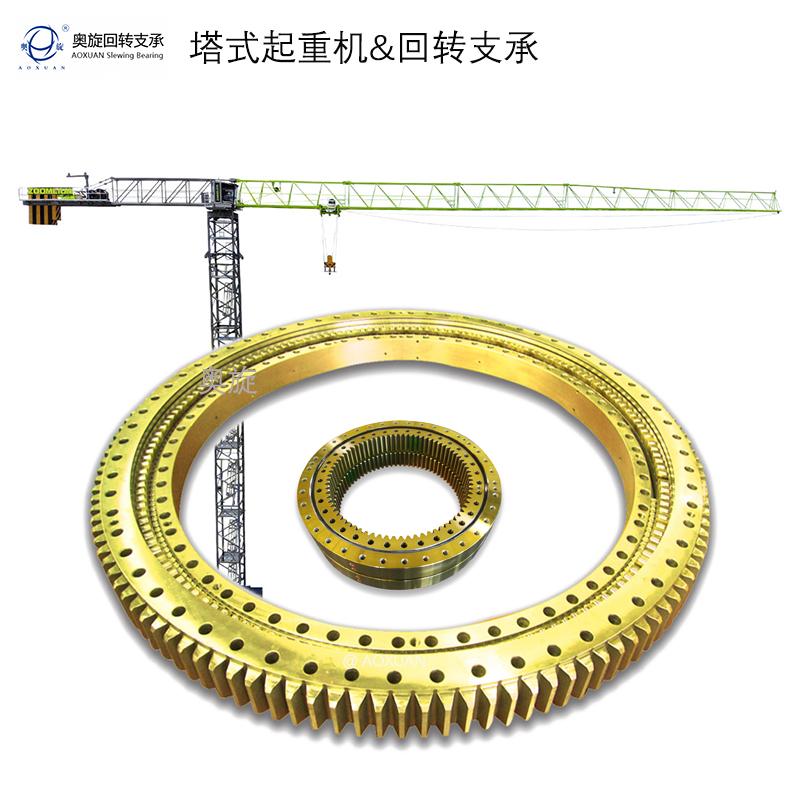

| Brand: | AOXUAN |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Insulation |

| Label: | SLEWING RING , SLEWING BEARING , Turntable Bearing |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

The tower crane, also called tower crane for short, originated in Western Europe. A rotating crane with a boom mounted on the upper part of a towering tower.

Large working space, mainly used for vertical and horizontal transportation of materials and installation of building components in building construction.

It is composed of metal structure, working mechanism and electrical system. Metal structure includes tower body, boom and base. The working mechanism has four parts: lifting, luffing, slewing and walking

Changzhou Aoxuan Heavy Bearing Co., Ltd. is located in the beautiful and rich Yangtze River Delta, with convenient transportation and comprehensive industrial support. The company covers an area of 33000 square meters, with a building area of 23000 square meters. It has more than 150 sets of production and processing equipment and testing equipment.

The main products are: slewing bearing, slewing drive and cross roller bearing. It is mainly used in engineering machinery, industrial robots, port machinery, construction machinery, truck cranes, metallurgical machinery, single-axis and two-axis tracking systems for solar photovoltaic power generation systems and small wind power stations.

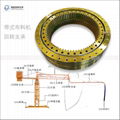

The tower crane is divided into two types: upper rotary type and lower rotary type:

1、 Upper-rotating tower crane: the tower body does not rotate, and the boom and balance arm above the slewing bearing rotate fully around the center line of the tower body through the slewing mechanism. According to the use requirements, it can be divided into running type, fixed type, attached type and internal climbing type. The traveling tower crane can run along the track, with a wide range of work and wide application, and is suitable for multi-storey building construction; If the crane base is fixed on the rail or the tower body is directly fixed on the foundation, it will become a fixed tower crane with a long boom; If the tower body of a fixed tower crane is connected to the building with an attachment rod at a certain height, it is an attached tower crane. It uses a tower body height connection device to make the upper rotating part of the crane increase with the height of the building, and is used for high-rise building construction; The crane installed in the elevator shaft and other shafts or connected holes and using hydraulic cylinders to make the crane climb up the shaft according to the construction process is called internal climbing tower crane. It saves part of the tower body, has a large service range and does not occupy the construction site, but has certain requirements for the structure of the building.

2、 Lower rotary tower crane: the slewing bearing is installed between the base and the turntable. Except for the traveling mechanism, other working mechanisms are arranged on the turntable to rotate together. In addition to the track type, there are also track type and tire type with track chassis and tire chassis as walking devices. It has a low center of gravity, can be disassembled and transferred as a whole, is light and flexible, and is widely used, and is suitable for multi-storey building construction.

Order process:

1. Consult customer service 2. Explain requirements 3. Confirm drawings 4. Sign contracts 5. Arrange production 6. Deliver goods from warehouse 7. Confirm receipt.

Under normal circumstances, the products are delivered in 3-7 days, and are now processed in 25-35 days, and customized products are delivered in about 45 days. Welcome to consult.

Member Information

| Changzhou Aoxuan Heavy Bearing CO.,LTD. | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 13601505067 |

| Contact: | Alex (Sale) |

| Last Online: | 08 Jul, 2023 |

Related Products of this Company

-

Slewing Bearing Ring for Hitachi Ex100

-

Welding Displacement Mechanical Joint

-

Construction Machinery Accessories

-

Aoxuan Slewing Bearing Ring of Excavator

-

Mechanical Joint of Rotary Table Bearing

-

Slewing Bearing Ring of Sumitomo

-

Tri-ROW Roller Slewing Ring (Series 13)

-

Joint Bearing of Concrete Distributor

-

Slewing Ring for Bottle Handling Machine

-

Single-Row Four Point Contact Ball