| Model: | - |

|---|---|

| Brand: | AOXUAN |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Insulation |

| Label: | slewing ring , turntable bearing , slewing bearing |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

In China, welding positioner is a young product. Due to the difference in the development level between manufacturing industries, many enterprises have not equipped welding positioner for their welding stations; At the same time, relevant research is also relatively weak.

So far, there is no special work to study its definition and classification. It is impossible to normalize its address. The same equipment, different enterprises and different people may have different titles.

Such as: tire rotation, turntable, turntable, positioner, positioner, etc. It needs to be given a definition. It changes the welding operation that may require vertical welding, overhead welding and other welding operations that are difficult to ensure the welding quality.

Thus, the welding quality is guaranteed, the welding productivity and the safety of the production process are improved.

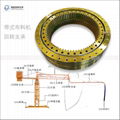

The slewing bearing is one of the important parts of the positioner electric welding machine. It can realize the function of the positioner and act as a flexible positioner joint. The degree of freedom of the positioner requires the slewing bearing to have higher accuracy and life.

Single-row four-point contact ball slewing bearing is composed of two seat rings, with compact structure, light weight, four-point contact between steel ball and arc raceway, and can bear axial force, radial force and overturning moment at the same time.

Technical requirements:

1 Slewing drive: Slewing drive shall realize stepless speed regulation and be reversible. Within the slewing speed range, the speed fluctuation under load shall not exceed 5%.

2 Tilt drive: the tilt drive shall be stable, without shaking under load, and the whole machine shall not overturn. If the load Q exceeds 25kg, it shall have power drive function., The limit device shall be set to control the tilt angle, and the angle indication sign shall be provided. The tilting mechanism shall have self-locking function, and shall not slide under heavy load, safe and reliable.

3 Others: The positioner control part shall be equipped with a linkage interface for automatic welding. The positioner shall be equipped with a conductive device to prevent the welding current from passing through the bearing, gear and other transmission parts. The resistance of conductive device shall not exceed 1m Ω, and its capacity shall meet the requirements of welding rated current. Electrical equipment shall comply with relevant provisions of GB/T 4064. The structure of the workbench shall be convenient for clamping the workpiece or installing the fixture, and its structure form can also be determined through consultation with the user. The relationship between heavy load and eccentric distance and center of gravity distance shall be described in the positioner operation manual.

Slewing bearing application: welding displacement machinery can be divided into three categories:

1 Weldment positioner: including welding positioner, welding roller frame, welding turntable and welding turner.

2. Displacement machine of welding machine: including welding operator and electroslag welding stand.

3 Welder displacement machinery: including welder lift, etc.

Order process:

1. Consult customer service 2. Explain requirements 3. Confirm drawings 4. Sign contracts 5. Arrange production 6. Deliver goods from warehouse 7. Confirm receipt.

Under normal circumstances, the products are delivered in 3-7 days, and are now processed in 25-35 days, and customized products are delivered in about 45 days. Welcome to consult.

So far, there is no special work to study its definition and classification. It is impossible to normalize its address. The same equipment, different enterprises and different people may have different titles.

Such as: tire rotation, turntable, turntable, positioner, positioner, etc. It needs to be given a definition. It changes the welding operation that may require vertical welding, overhead welding and other welding operations that are difficult to ensure the welding quality.

Thus, the welding quality is guaranteed, the welding productivity and the safety of the production process are improved.

The slewing bearing is one of the important parts of the positioner electric welding machine. It can realize the function of the positioner and act as a flexible positioner joint. The degree of freedom of the positioner requires the slewing bearing to have higher accuracy and life.

Single-row four-point contact ball slewing bearing is composed of two seat rings, with compact structure, light weight, four-point contact between steel ball and arc raceway, and can bear axial force, radial force and overturning moment at the same time.

Technical requirements:

1 Slewing drive: Slewing drive shall realize stepless speed regulation and be reversible. Within the slewing speed range, the speed fluctuation under load shall not exceed 5%.

2 Tilt drive: the tilt drive shall be stable, without shaking under load, and the whole machine shall not overturn. If the load Q exceeds 25kg, it shall have power drive function., The limit device shall be set to control the tilt angle, and the angle indication sign shall be provided. The tilting mechanism shall have self-locking function, and shall not slide under heavy load, safe and reliable.

3 Others: The positioner control part shall be equipped with a linkage interface for automatic welding. The positioner shall be equipped with a conductive device to prevent the welding current from passing through the bearing, gear and other transmission parts. The resistance of conductive device shall not exceed 1m Ω, and its capacity shall meet the requirements of welding rated current. Electrical equipment shall comply with relevant provisions of GB/T 4064. The structure of the workbench shall be convenient for clamping the workpiece or installing the fixture, and its structure form can also be determined through consultation with the user. The relationship between heavy load and eccentric distance and center of gravity distance shall be described in the positioner operation manual.

Slewing bearing application: welding displacement machinery can be divided into three categories:

1 Weldment positioner: including welding positioner, welding roller frame, welding turntable and welding turner.

2. Displacement machine of welding machine: including welding operator and electroslag welding stand.

3 Welder displacement machinery: including welder lift, etc.

Order process:

1. Consult customer service 2. Explain requirements 3. Confirm drawings 4. Sign contracts 5. Arrange production 6. Deliver goods from warehouse 7. Confirm receipt.

Under normal circumstances, the products are delivered in 3-7 days, and are now processed in 25-35 days, and customized products are delivered in about 45 days. Welcome to consult.

Member Information

| Changzhou Aoxuan Heavy Bearing CO.,LTD. | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 13601505067 |

| Contact: | Alex (Sale) |

| Last Online: | 08 Jul, 2023 |

Related Products of this Company

-

Double-ROW Slewing Bearing Ring ( Series

-

Tri-ROW Roller Slewing Ring (Series 13)

-

Joint Bearing of Concrete Distributor

-

Slewing Ring for Bottle Handling Machine

-

Single-Row Four Point Contact Ball

-

Slewing Bearing is Suitable for

-

Aoxuan Slewing Bearing is Suitable for

-

Slewing Bearing Ring for Hitachi Ex100

-

The slewing Bearing is Used as The Main

-

Construction Machinery Rotary Table