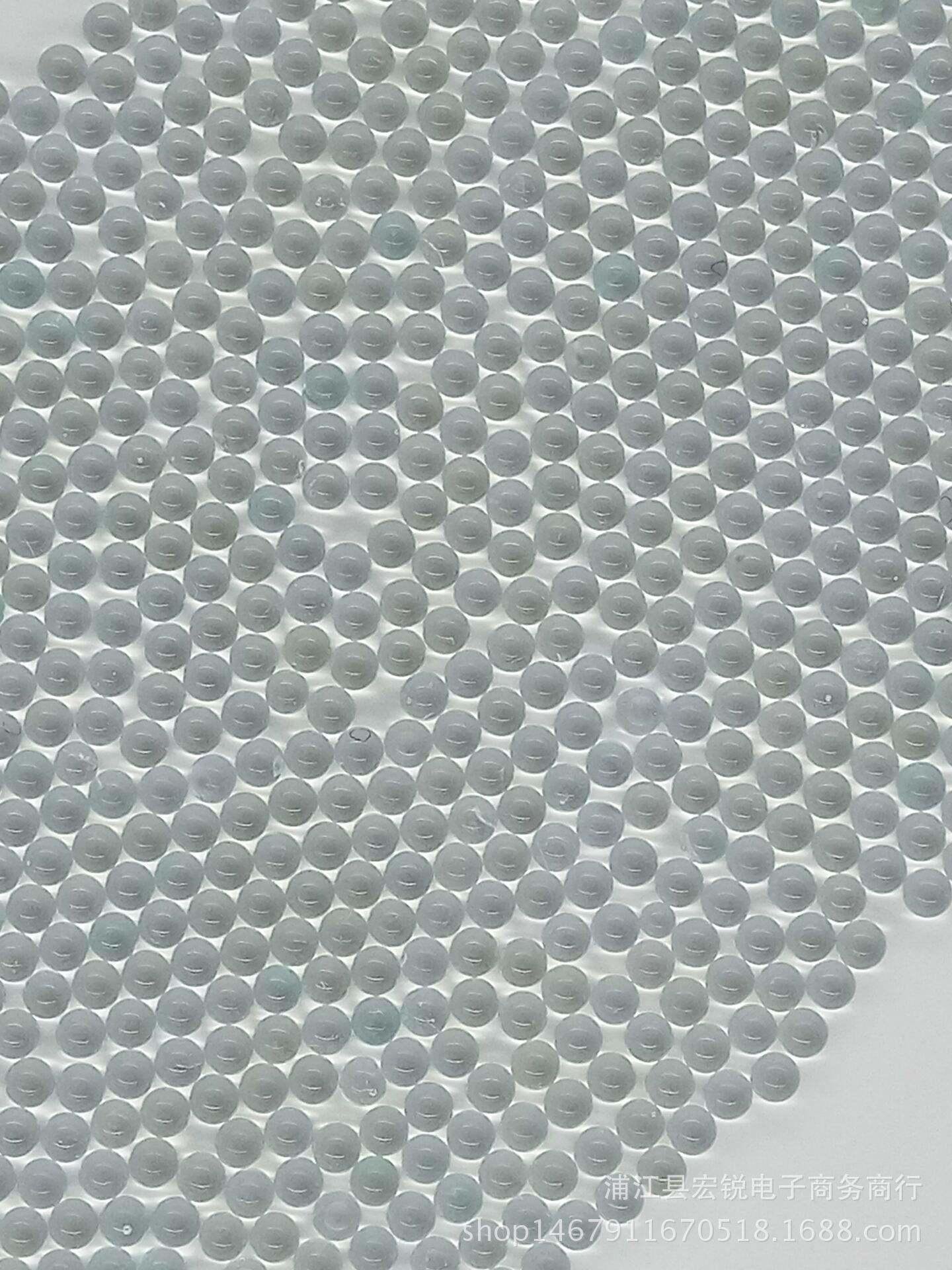

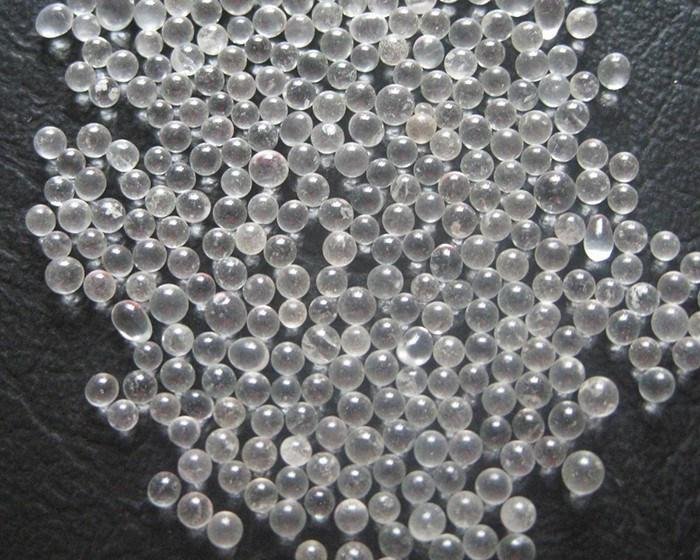

Characteristics of ground glass beads:

1. The chemical composition is inert silicon dioxide without chemical activity interference;

2. Round elastic particles, impact resistant, recyclable, low loss;

3. The abrasion of spray is small, and the service life of nozzle is prolonged;

4. The appearance of the ball will not damage the processing surface and fine dimensions;

5. After disposal, the surface of the workpiece is lubricated, with a special aesthetic feeling, improving product value;

6. Suitable for dry and wet sand blasting operations;

7. Fine glass beads used for metal micro cracks are easy to appear after wet sandblasting;

8. The processed workpiece has the advantages of matt effect, highlighting the nature of metal, non rusting, and no need to stop pickling and rust removal

Use of ground glass beads:

1. Beading aviation parts to relieve stress, increase fatigue strength, and reduce friction and wear;

2. Used for grinding paint and color paste;

3. Anode treatment and pre plating treatment can increase adhesion in addition to cleaning;

4. Aesthetic processing such as welding bead cleaning and removal of external scratches on stainless steel workpieces;

5. Cleaning and rust removal of wire cutting molds;

6. Removing dirt from rubber molds;

7. For road marking and reflection;

8. Used for surface decoration of artworks;

| No. |

Particle size(mm) |

Roundness |

Product No. |

| 1 |

0.6-0.8 |

95% |

SD-YM-0608 |

| 2 |

0.8-1.2 |

95% |

SD-YM-0812 |

| 3 |

1.2-1.5 |

95% |

SD-YM-1215 |

| 4 |

1.5-2.0 |

95% |

SD-YM-1520 |

| 5 |

2.0-2.5 |

90% |

SD-YM-2025 |

| 6 |

2.5-3.0 |

90% |

SD-YM-2030 |

| 7 |

3.0-4.0 |

90% |

SD-YM-3040 |

| 8 |

4.0-5.0 |

90% |

SD-YM-4050 |

| 9 |

6.0 |

100% |

SD-YM-60 |