1.Use of shot peened glass beads

*Surface matting treatment of stainless steel products

* Used for cleaning various molds

* It can remove tensile stress of various parts and increase fatigue life

* Cleaning and removing edge burrs before tin coating on semiconductor devices and plastic packaging tubes

* Shot peening enhanced polishing of medical devices, textile machinery, and various hardware products

* Cleaning and deburring of various metal pipes and nonferrous metal precision castings

2.Characteristics of shot peened glass beads:

* Both soft and hard - Made from high-quality materials, it has a certain mechanical strength, a content of sio2 greater than or equal to 68%, a hardness of up to 6-7 Mohs, and sufficient elasticity. It can be used repeatedly for several times, and is not easy to break. The sprayed components have the same effect, and the service life of ordinary glass beads is more than 3 times longer.

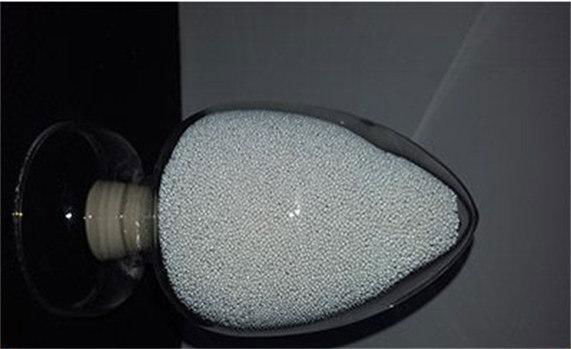

*Good uniformity - the roundness rate is greater than or equal to 80%, and the particle size is uniform. After spraying, the brightness coefficient of all parts of the sandblasting device remains uniform, and it is not easy to leave a watermark.

* Irreplaceability - As an abrasive material, shot peening glass beads have the following advantages over any other abrasive material: they have a longer service life than any other medium except metal abrasive materials, are made of non alkaline soda lime glass materials, have good chemical stability, do not contaminate the processed metal, can accelerate cleaning, while maintaining the processing accuracy of the original object

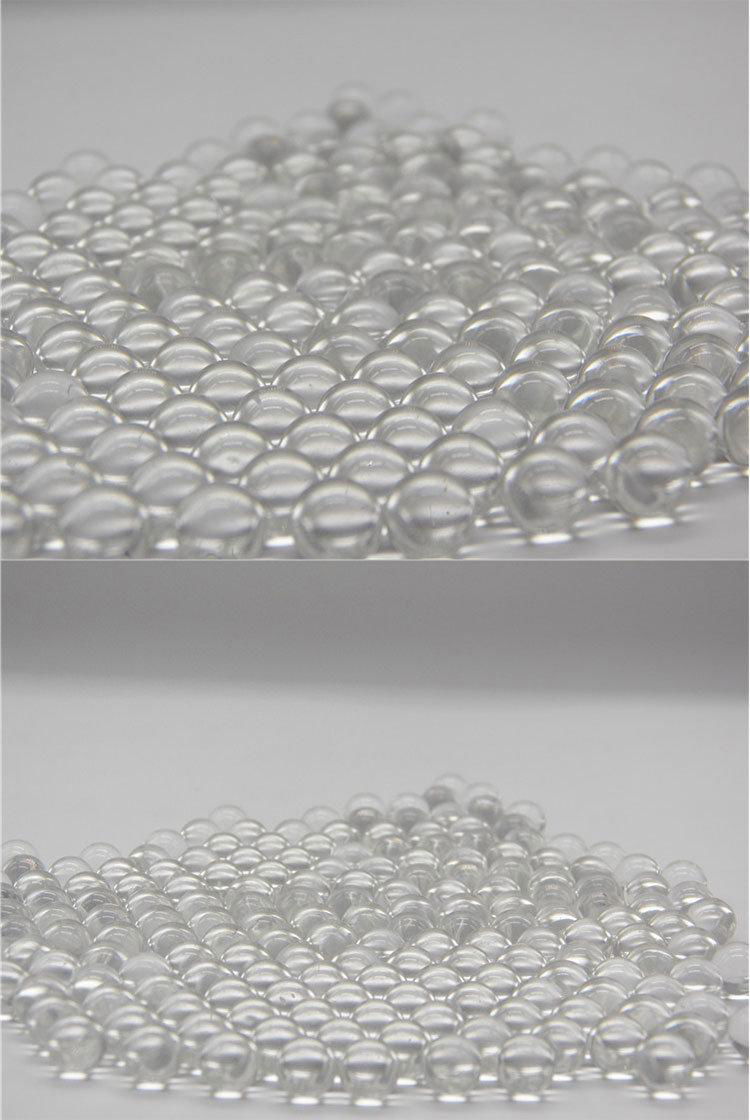

* Smooth and free of impurities - the appearance is spherical particles without impurities; The surface is smooth and has a good finish, meeting international and domestic standards

3.Product technical indicators:

* Chemical composition: SiO2>67%, CaO>8.0% MgO>2.5% Na2O0.15 Other 2.0%

* Specific gravity: 2.4-2.6g/cm3 Bulk density: 1.5g/cm3 Mohs hardness: 6-7 Mohs Rockwell hardness: 48-52 HRC Appearance: smooth, round, transparent glass without impurities Rounding rate: ≥ 85%

* Magnetic particles do not exceed 0.1% by weight of the product

*The bubble content in the glass bead is less than 10%

* Does not contain any silicone components

| No |

sandblast cabinet(mm) |

model |

| 1 |

0.850-0.425 |

30# |

| 2 |

0.425-0.250 |

60# |

| 3 |

0.250-0.180 |

80# |

| 4 |

0.180-0.150 |

100# |

| 5 |

0.150-0.106 |

120# |

| 6 |

0.106-0.077 |

180# |

| 7 |

0.077-0.061 |

220# |

| 8 |

0.061-0.054 |

280# |

| 9 |

0.054-0.000 |

325# |