| Model: | MF-01 |

|---|---|

| Brand: | TopTiTech |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Products |

| Label: | titanium plate , metal porous plate , porous sintered disc |

| Price: |

US $25

/ pc

|

| Min. Order: | 1 pc |

Product Description

Product Introduction

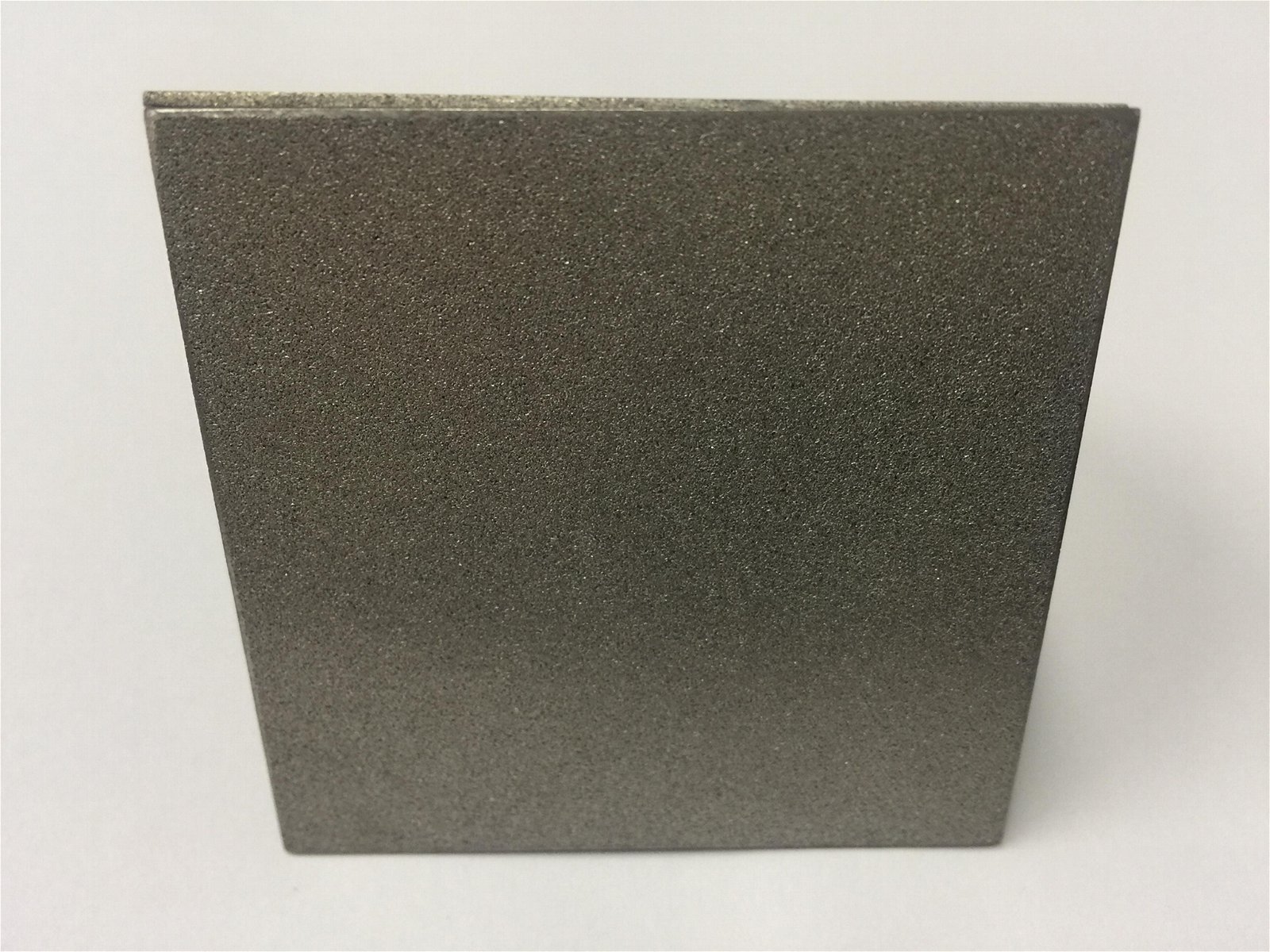

Sintered titanium plate is a kind of titanium product, which is widely used in various industries such as chemical industry, medical treatment and food processing due to its excellent corrosion resistance and high strength. The porous titanium plate produced using the sintering process is to press the titanium powder into the desired shape and then sinter at high temperature.

Titanium powder particles link together during sintering to form a solid structure with interconnecting pores of specified size and shape. The sintered titanium plates produced have a high strength-to-weight ratio and are resistant to high temperatures and harsh chemical conditions.

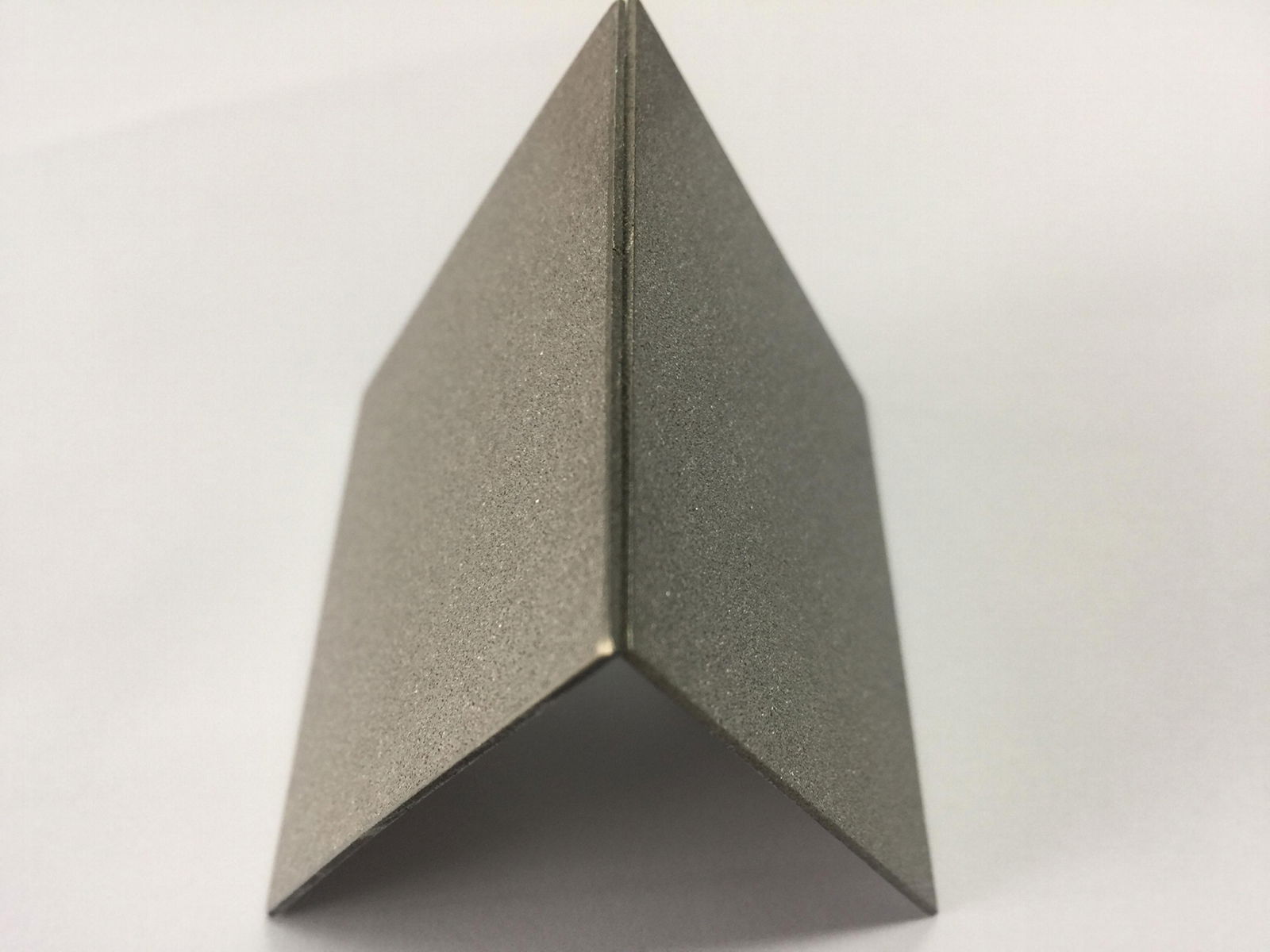

Sintered titanium plates can be tailored to suit customer needs, such as pore size, pore dispersion, and thickness. To meet a wide range of applications, we can also manufacture porous titanium plates with complex geometries such as cylindrical, conical, and flat shapes. To ensure product quality, we conduct strict tests on porous titanium plates, including pore size distribution analysis, compressive strength test and corrosion resistance test.

Product parameters

Brand: TOPTITECH

Origin: Baoji, China

Filtration grade: 0.2-100um

Thickness: above 1mm

Shape: square, round, shaped

Size: 300*800mm can be customized

Pressure: 0.2Mpa

Features

1. High strength and toughness: During the sintering process, the titanium powder particles are closely combined with each other, so that the sintered titanium plate has high strength and toughness, and can withstand certain impact and pressure.

2. Excellent corrosion resistance: Titanium itself has good corrosion resistance, and a uniform microporous structure can be formed through sintering, which further improves the corrosion resistance of titanium plates.

3. Can be made into complex shapes: through the sintering process, titanium sheets of various complex shapes and pore diameters can be made to meet the needs of different industries and applications.

4. Adjustable pore size and porosity: By adjusting the sintering process parameters, the pore size and porosity of the titanium sheet can be controlled to obtain the performance required for different applications such as filtration, separation, and adsorption.

Applications

1. Used as a filter: use its porous filtration and separation to purify liquids and gases. For example, it is used to purify fuel oil and air on airplanes and automobiles; to filter various liquids and gases in the chemical industry; to filter radioactive particles in exhaust gases from the atomic energy industry;

2. Utilize the function of its pores to manufacture porous electrodes, fire extinguishing devices, antifreeze devices, high temperature resistant nozzles, etc. Porous electrodes are mainly used in electrochemistry. The fire extinguishing device uses its anti-flow effect to prevent explosions, such as flame explosion arresters for gas welding. The antifreeze device utilizes its holes to feed preheated air or special liquid to prevent the wings and empennage from freezing. The high temperature resistant nozzle uses the principle of sweating on the surface to cool the hot surface, which is called sweating material.

3. Porous titanium is also a good porous electrode material for water electrolysis, and it can be coated with platinum, iridium, ruthenium and other metals to enhance its electrochemical performance. The current PEM water electrolysis hydrogen production equipment widely uses porous titanium plate as its anode diffusion electrode material.

How to purchase porous sintered titanium plate?

A. Materials to be delivered;

B. Corrosion problems;

C. Special operating conditions involving pressure, temperature, etc.;

D. Pollutants encountered;

E. Required shape, dimensions and tolerances;

F. Required flow and pressure allowed by the filter unit.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer´s designated place without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH —— BAOJI YINGGAOCO., LTD

Website:https://www.toptitech.com/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Member Information

| TopTiTech--Baoji YingGao Metal Materials co.,ltd. | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 19992203758 |

| Contact: | Karry Kang (Sales Manager) |

| Last Online: | 21 Mar, 2023 |

Related Products of this Company

-

Titanium Rod Filter Element From

US $30

-

Sintered metal flame arresters

US $25

-

SUS316L hydrogen dissolving rod From

US $25

-

Sintered Titanium Felt Titanium Fiber

US $30

-

Sintered Metal Gas Diffusion Stones

US $25

-

Porous Titanium Plate For MEA From

US $10

-

Stainless steel pleated filter for high

US $30

-

Customized metal microporous filter

US $20

-

Sintered Porous Metal Powder Filters

US $25

-

Customized Sintered Stainless Steel

US $10