| Model: | MF-02 |

|---|---|

| Brand: | TopTiTech |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Products |

| Label: | Metal Filter , sintered porous , filtration |

| Price: |

US $25

/ pc

|

| Min. Order: | 1 pc |

Product Description

Product Introduction

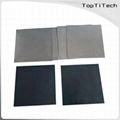

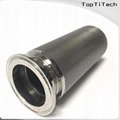

Metal powder serves as the only raw material for the sintered metal powder filter; no binders are used. It is generated by cold isostatic pressing and then sinters at high temperatures. By adjusting the process parameters and metal powder particle size, the pore size and distribution of the component can be changed. Utilize the pore structure, material composition, compressive strength, and other characteristics of different filter materials to develop filter products suitable for users.

When the filter cake on the surface of the sintered metal powder filter element reaches a certain thickness, due to its high-strength performance characteristics, by backwashing or backflushing the filter element under a specific reverse pressure, the filter element can be cleaned and reused.

Product parameters

Material: stainless steel powder, brass powder, titanium powder

Diameter: Φ14mm Φ20mm Φ30mm Φ50mm Φ60mm Φ80mm Φ90mm Φ100mm

Length: 5 inches (125mm) 10 inches (250mm) 12 inches (300mm) 20 inches (500mm) 30 inches (750mm) 40 inches (1000mm)

Interface form: M20 M30 222 226

Filtration accuracy: 0.45 micron 1 micron 3 microns 5 microns 10 microns 20 microns 30 microns 50 microns 80 microns 100 microns

Features

Strong resistance to corrosion

An inert metal with exceptional corrosion resistance is titanium. Strong alkali and strong acid media can be filtered using the titanium metal rod filter element. It has a wide range of applications in the chemical industry and in the filtering of the pharmaceutical industry´s organic lysozyme production process.

Good tolerance to high temperatures

The titanium filter element has a high temperature resistance that goes up to 300°C. In operational situations with high temperatures, this function is frequently used. The temperature resistance of the filter element made of polymer materials is normally limited to 50°C. The support and filter membranes will alter if the temperature goes beyond 50°C. It is frequently employed in the filtration of high-temperature liquids and steam filtration (steam filtration in fermentation processes), despite having a significant accuracy variance.

Superior mechanical qualities

With external pressure of 20 kg and internal pressure of 10 kg of destructive force, the titanium rod filter element has strong mechanical qualities and may be utilized in high pressure and quick filtration processes. The pore size of other polymer filter components will fluctuate or even break down when the external pressure is more than 0.5 MPa.

Good regeneration

Due to its superior corrosion resistance, high temperature resistance, and high strength performance, titanium rod filters have a good regeneration effect. There are two types of regeneration: chemical regeneration and physical regeneration treatment.

Physical regeneration method:

(1) Pure water recoil

(2) Steam blowback

(3) Ultrasonic cleaning

Chemical treatment method:

(1) Alkaline washing

(2) pickling

Applications

Catalyst filtration and separation;

Filtration of fluidized bed tail gas in petrochemical facilities and of high-temperature gas in the petrochemical industry;

High-temperature flue gas purification in the metallurgical industry;

Various high-temperature gases and liquids being filtered;Porous metal powder filter materials have a wide range of applications. In addition to the above mentioned categories, it can also be used in many other fields: such as pneumatic components; ammonia, ammonia water, chlorine, fluorine gas filtration, polyester filtration; methanol, benzene and other organic solvent filtration; protein filtration, hydraulic pressure Oil, fuel oil filtration, natural gas filtration, steam, high-temperature gas filtration, oil field water injection filtration; sewage filtration, lye filtration, fine filtration of liquid medicine and food and beverage; industries of chemical products such as dyes, inks, paraffin and sulfur.Traditional filter paper, carbon rods, diatomite, polyethylene filter elements, and different foreign industrial and mining filter components can all be replaced with porous metal powder.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer´s designated place without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH —— BAOJI YINGGAOCO., LTD

Website:https://www.toptitech.com/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Member Information

| TopTiTech--Baoji YingGao Metal Materials co.,ltd. | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 19992203758 |

| Contact: | Karry Kang (Sales Manager) |

| Last Online: | 21 Mar, 2023 |

Related Products of this Company

-

Metal Porous Sintered Titanium Plate

US $25

-

Sintered Titanium Felt Titanium Fiber

US $30

-

Stainless steel powder sinter filters

US $30

-

Sintered porous titanium plate for PTL

US $20

-

Titanium electrode plate for water

US $25

-

Sintered Metal Gas Diffusion Stones

US $25

-

Stainless steel pleated filter for high

US $30

-

Sintered metal flame arresters

US $25

-

SUS316L hydrogen dissolving rod From

US $25

-

Multi-Layer Metal Sintered Mesh Filter

US $30