| Model: | Half Round Rain |

|---|---|

| Brand: | Wadley |

| Origin: | - |

| Category: | Industrial Supplies / Construction Machine |

| Label: | Round Gutters Making , Half Round Gutter Ro , Aluminim Seamless Gu |

| Price: |

US $9900

/ pc

|

| Min. Order: | 3 pc |

Product Description

Product Overview

2024 Latest Arrival Downspout And Portable Gutter Roll Forming Machine For Roof Drainage:

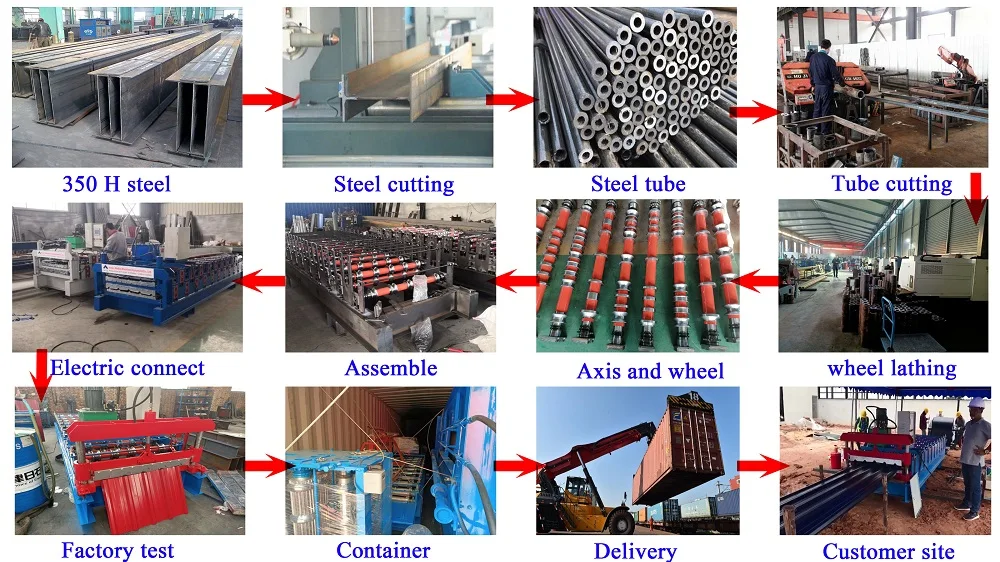

The gutter machine can use color steel or aluminum plate to make the gutter plate. The forming plate is rolled, closed, and then bent and narrowed by special equipment. It has good weather resistance, simple design, simple installation, safe and durable, and noble. Elegant. The gutter board can be sprayed with rich colors according to the individual needs of users, and its metal texture and beautiful shape can bring a strong expressive force to the building. 1. The whole machine is controlled by PLC, and multiple safety protections can be set to effectively avoid accidents; 2. The bed is made of steel plate welded parts and tempered to effectively eliminate internal stress and the body is not easy to deform; 3. The forming frame is welded by channel steel; 4. The roll shaft is made of 45# steel, which has been quenched and tempered; 5. The material of forming punching and shearing die is Gr12;

PRODUCT SPECIFICATIONS

|

No |

Item |

Data |

|

1 |

Raw material width |

300-600 mm |

|

2 |

Sheet effective width |

80-200 mm |

|

3 |

Raw material |

Color steel sheet , Stainless steel or galvanized steel sheet |

|

4 |

Material thickness |

0.3-0.8 mm or customized |

|

5 |

Forming roller material |

45# steel plated with chrome |

|

6 |

Shaft diameter |

40 mm |

|

7 |

Forming roll station |

8-16 steps |

|

8 |

Main motor power |

3 KW 4 KW 5.5 KW(according to type) |

|

9 |

Hydraulic power |

4 KW (according to type) |

|

10 |

Control system |

PLC control |

Rain Gutter Roll Forming Machine is made by cold-formed forming process. It is widely used by people for its energy-saving and environmentally friendly features. It uses less steel to complete the required specified load, and no longer depends on increasing the amount of plates or materials. The mechanical properties of the steel can meet the load requirements, but the mechanical properties of the steel can be improved by changing the cross-sectional shape of the steel product. Cold bending is a material-saving and energy-saving new metal forming process and new technology. Cold bending is a multi-pass forming and rolling that is arranged in sequence to continuously bend the coils and other metal plates and strips in the transverse direction. Make profiles of specific cross-sections

Successful Project

Project in Thailand

Project in India

Project in Russia

Company Profile

Henan Wadley CNC Machinery Co.,Ltd. is a manufacture specializing in custom cold roll forming equipment and automatic production lines,we can manufacture hundred types roll forming machines and all kinds of architecture profliles. Engineers and technicians are rich in experience of designing developing and manufacturing of machines to provied customers with customized designs.Our products and sold to many countries and regions around the world.and we have established long-term cooperative relationships with customers.

Main products: the company operates various types of products with various specifications, including cold bending forming equipment and other mechanical equipment, such as tile pressing machine, machine tool, tapping machine, slotting machine, boring machine, air hammer, gear hobbing machine, nail making machine, marking machine, etc. Wide range of products, welcome to inquiry.

Our Service:

SIMILAR PRODUCTS

IBR Sheet Roll Forming Machine

Glazed Tile Roll Forming Machine

Shutter Door Forming Machine

Ridge Cap Roll Forming Machine

Supermarket Shelves Forming Machine

Metal Fence Forming Machine

Member Information

| Henan Wadley Cnc Machinery Co., Ltd. | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Trading Company |

| Phone: | 15937177506 |

| Contact: | Yin (boss) |

| Last Online: | 08 May, 2024 |

Related Products of this Company

-

Three layer roll forming Machine

US $11200

-

Downspout Roll Forming Machine,drip Edge

US $9800

-

Roof ridge cap roll forming machine,Roof

US $7800

-

Metal Rolling Shutter Door Roll Forming

US $7500

-

Gusset Plate Sheet Roll Forming Machine

US $8500

-

Ibr Roof Sheet Roll Forming

US $7500

-

New condition shelf forming machine

US $25000

-

High Speed Metal Floor Deck Roll Forming

US $25000

-

Z Strut Channel Roll Forming Machine,Z

US $7900

-

C Profile Purlin Roll Forming Machine,c

US $6500