| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Metallic Powder |

| Label: | Copper inlaid tungst , Plasma Electrode , Semiconductor Nozzle |

| Price: |

¥450

/ kilo

|

| Min. Order: | 1 kilo |

Product Description

Are you on the hunt for a reliable supplier to replace your electrodes and nozzles? Have you scoured the internet, only to find discrepancies, assembly issues, subpar spray results, or disappointingly short product lifespans compared to the original manufacturer?

Look no further! We specialize in delivering superior quality at unbeatable prices. Bid farewell to the challenges of finding the perfect fit for your needs. Whether you crave outstanding performance, precise product dimensions, or a seamless setup without the constant hassle of adjusting machine parameters, we have the solution.

Reach out to us today, and let’s tackle the challenges you’re facing head-on. Elevate your coating experience with electrodes and nozzles that not only meet but exceed your expectations – quality, precision, and longevity, all under one roof!

Below you will find more introduction of products:

In the process of plasma spraying, metal or ceramic powders are melted in a plasma arc and then rapidly sprayed onto the surface of the workpiece. This method allows for the deposition of coatings that are impermeable and have strong adhesion on various tools and equipment components. When used in a spraying gun, our electrode must withstand instantaneous plasma temperatures exceeding 12,000°C.

This momentary high temperature and pressure are not an issue for our F4 electrode. Our company utilizes a back-casting production process to create a seamless connection between tungsten and copper, resulting in exceptionally high strength. As a result, our electrode can provide long-term stable operating conditions, extending its service life.

While Metco’s F4 plasma spray gun is widely used in the market, it also faces challenges such as high prices and other issues. Our company is committed to producing high-performance and stable plasma spray gun electrode and nozzle accessories, contributing to an extra alternative.

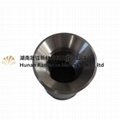

Structure of Plasma Spray Metco F4 Electrode

The F4 electrode also adopts the back-casting method to connect copper alloy and tungsten alloy. Through this integral connection method, the two alloys connect seamlessly.

In contrast to the soldering method, where two alloys connect through solder as an intermediate medium but is challenging to achieve 100% connection, our approach results in higher strength. This is crucial for withstanding the immense pressure and high temperatures faced inside the gun body, preventing uneven heat conduction and cracks.

Plasma Spray Metco F4 Electrode Models:

|

Type |

Torch Producer |

Part Name |

OEM Code |

|

RTE-F4 |

Metco |

F4 Electrode |

1072006 |

|

RTN-F4 |

Metco |

F4 Nozzle |

1072006 |

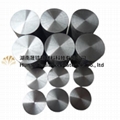

Advantages of Plasma Spray Metco F4 Electrode:

1. Our company has been focusing on the production of pure tungsten and tungsten alloy materials for many years, possessing a deep understanding of material structure and performance. To meet the strict material requirements of plasma spraying, we have improved and treated the tungsten insertsused for plasma spraying electrodes. Through densification treatment, the tungsten electrode forms a uniform and fine-grained crystal structure, enhancing hardness and density, resulting in quick arc initiation and outstanding resistance to arc burning, ensuring a long service life.

2. Using a unique back-casting technology, our plasma spray electrode and nozzle achieve a seamless connection between tungsten and copper, with a bonding strength of up to 127 MPa, far exceeding the bonding strength of traditional soldering methods. This connection method not only increases contact area and resistance uniformity but also enhances heat dissipation, ensuring higher stability and longer service life for the nozzle and electrode.

3. To meet various customer usage requirements, we produce tungsten electrodes in multiple materials, ensuring excellent arc initiation performance and erosion resistance. After studying and analyzing plasma spray guns, our products can perfectly adapt to various spray guns without the need for additional adjustments to spraying parameters. Our product range is comprehensive, widely applicable to F4, 9M, SG-100, and plamaspray guns from companies such as Metco, GTV, FST, AMT AG, Praxair, etc.

4. With extensive experience, we produce various anodes and cathodes, offering customized processing based on customer samples or drawings and providing semi-finished products with seamless tungsten-copper bondings.

5. While there are many manufacturers of F4 electrodes in the market, many can only produce similar dimensions, with significant differences in service life and performance. As a professional manufacturer, we not only understand how to produce but also how to improve. Understanding customer usage, we can provide more professional on-site services.

Member Information

| Hunan Radiance Materials Co., Ltd. | |

|---|---|

| Country/Region: | Hu Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 19313019820 |

| Contact: | Elena (sales) |

| Last Online: | 27 Aug, 2024 |

Related Products of this Company

-

Tungsten Heavy Alloy Cylinders

-

Tungsten Alloy Anti-Vibration Boring Bar

-

High-Density Tungsten Allo Shielding for

-

Tungsten Alloy for Military Application

-

Radiation shielding tungsten alloy

-

High-Density Tungsten Alloy

-

Production of tungsten alloy cylinders

-

Tungsten shield parts Tungsten square

-

Tungsten Alloy Collimator Tungsten Alloy

-

Introduction of 9MB Tungsten Lined