| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Metallic Powder |

| Label: | Tungsten Pillar , Tungsten Rod , Tungsten gold tube |

| Price: |

¥450

/ kilo

|

| Min. Order: | 1 kilo |

Product Description

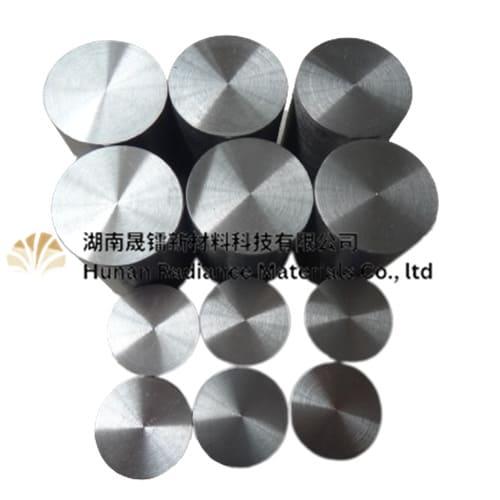

Description of Tungsten Alloy Cylinders

Tungsten alloy cylinders are produced by adding a small amount of nickel-iron or nickel-copper to tungsten powder and then using powder metallurgy. Tungsten alloy products are also known as high-density tungsten alloys. The high density of the product results in much greater weight than steel and lead in the same volume, making it ideal for applications with weight requirements.

Tungsten alloy cylinders are commonly used to make various counterweights, such as crankshaft weights, engine weights, and toy car weights.

Advantages of Tungsten Alloy Cylinders

1. The high density of tungsten alloy cylinders results in a small volume occupied.

2. Tungsten alloy cylinders are precisely manufactured, ensuring high product accuracy.

3. Tungsten alloy cylinders can be provided in various sizes and can also meet custom requirements.

Application of Tungsten Alloy Cylinders in Crankshafts

At low speeds, it is usually not necessary to provide balancing weights to counteract the rotating mass of crankshaft pins and parts of the connecting rod that can rotate with the crankpin. However, the forces imposed by these rotating masses increase proportionally with the square of the stroke and engine speed.

As the engine speed increases, the demand for providing balance also increases. The number of weights used on the crankshaft can vary. For example, some crankshafts have a pair of weights opposite each crank pin, while others may not require as many.

Balancing weights can be placed on either side of the connecting rod pin to compensate for external moments and minimize the number of internal moments, thereby reducing the amount of vibration and bearing loads. The result is a smoother and more durable engine.

The size and mass of tungsten alloy cylinders placed on the crankshaft can vary based on operating conditions and other factors such as the required bearing life of the crankshaft. Different numbers of tungsten alloy cylinders can be used to provide different engine performance advantages.

Tungsten alloy is an excellent material for balancing crankshafts. All engines require perfectly balanced crankshafts to ensure optimal performance. Incorrect crankshaft balance can have serious consequences, including shortened lifespan, excessive vibration, and power loss in the engine.

In high-performance engines and high-power diesel engines, the stresses caused by imbalance can lead to premature failure. The high density of tungsten alloy means it can be used to manufacture compact and highly durable counterweights for balancing crankshafts. Tungsten alloy crankshaft weights can be placed precisely where needed to provide optimal performance.

Tungsten alloy drive shaft weights are smaller than steel weights of the same weight, which also means that external balancing may not be required in engines with limited internal space.

Member Information

| Hunan Radiance Materials Co., Ltd. | |

|---|---|

| Country/Region: | Hu Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 19313019820 |

| Contact: | Elena (sales) |

| Last Online: | 27 Aug, 2024 |

Related Products of this Company

-

Tungsten Heavy Alloy Cylinders

-

Tungsten shield parts Tungsten square

-

Radiation shielding tungsten alloy

-

Tungsten Alloy Collimator Tungsten Alloy

-

Tungsten Alloy Anti-Vibration Boring Bar

-

F4 Plasma Spray Nozzles

-

SG-100 Plasma Thermal Spray Anode

-

Introduction of Plasma Spray Metco F4

-

Tungsten Alloy for Military Application

-

Production of tungsten alloy rods in