| Model: | PC |

|---|---|

| Brand: | weiersha |

| Origin: | Made In China |

| Category: | Construction & Decoration / Shaped Building Material |

| Label: | PC greenhouse , polycarbonate sheet , polycarbonate panel |

| Price: |

US $3.5

/ kg

|

| Min. Order: | 500 kg |

Product Description

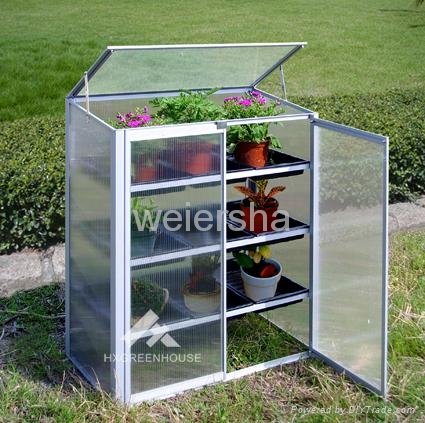

| polycarbonate greenhouse sheet of WEIERSHA manufacted under the most advanced technology and equipments,adopting polycarbonate resin as main raw materials, mixing with anti-UV absorbent and other accessory ingredient . PC corrugated roofing sheet have stable performance, not easy to be yellowing and becoming inferior. Also pc corrugated roofing sheet owns high ability to absorb and prevent ultraviolet ray approve to 99.9% effectively. | ||||||

Polycarbonate greenhouse sheet specification

|

||||||

|

Polycarbonate greenhouse sheet Properties Light transmission Fine light transmitting rate approve to 30~ 85%.

Applications of UV-Polycarbonate greenhouse

Notice when delivery, stockpile,installation

|

Member Information

| Weiersha Building Material Co.,Ltd | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15067675451 |

| Contact: | Cheryl lao (Sales representative) |

| Last Online: | 14 Jun, 2012 |

Related Products of this Company

-

greenhouse roofing,wall corrugated

US $3.77

-

polycarbonate corrugated roofing sheet

US $3.78

-

Greenhouse polycarbonate solid sheet

US $3.68

-

skylight polycarbonate hollow sheet

US $3.2

-

Roma polycarbonate corrugated sheet for

US $3.8

-

Clear polycarbonate solid sheet for

US $3.8

-

UV- protect polycarbonate corrugated

US $3.8

-

twin wall polycarbonate hollow roofing

US $3.5

-

corrugated polycarbonate roofing sheet

US $3.8

-

polycarbonate corrugated sheet

US $4