| Model: | AAC/AAAC/ACSR |

|---|---|

| Brand: | YITENG |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Optical Fiber, Cable & Wire / Other Wire & Cable |

| Label: | AAC Cable , AAAC CABLE , ACSR CABLE |

| Price: |

US $10

/ meter

|

| Min. Order: | 500 meter |

| Last Online:01 Mar, 2017 |

Packaging & Delivery

| Packaging Details: | Wooden drums,steel drums |

|---|---|

| Delivery Detail: | Deliver within 3 weeks |

Detailed Product Description

AAC,AAAC,ACSR,ACSR/AW,AACSR&ACAR conductor widely used in power transmission lines with various voltage levels. since they have such good characteristics as simple structure, convenient installation and maintenance, low cost for the line, large transmission capacity and are also suitable for laying across rivers and valleys where special geographical teatures exist.

1. Specification:

(1) all aluminium conductor (AAC)

(2) all aluminimum alloy conductor(AAAC)

(3) aluminum conductor steel reinforced (ACSR)

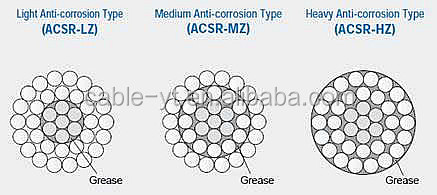

(4) anti-corrosion type ACSR

(5) aluminimum conductor aluminimum clad steel reinforced(ACSR/AW)

(6)rear earth aluminimum conductor steel reinforced(ACSR/RE)

(7)aluminimum conductor aluminimum alloy reinforced(ACAR)

2. Elative manufacturing standards: IEC83, IEC1089, 31, B232, BS215, DIN48204

1). Standard: IEC61089, BS215 part2, ASTM B232, DIN48204, BS EN50182

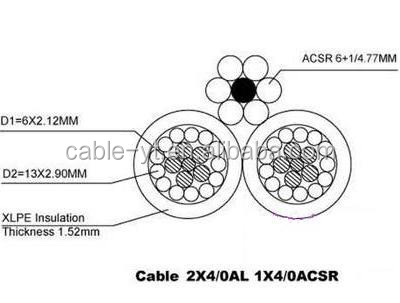

2). Specification: ACSR is composed by bare concentric-lay-stranded galvanized steel wire(s) with aluminum wires surrounded by one or more layers of helically. Greased ACSR can also be supplied.

3). Application: ACSR is widely used in overhead electric power transmission and distribution lines with various voltage levels

All Aluminum Conductor(AAC)& Aluminum Conductor Steel Reinforced(ACSR))for ASTM (AAC, ACCR, AAAC, ACSR) Generally Confirming to IS 398 (Part-I, II, IV), IEC-228

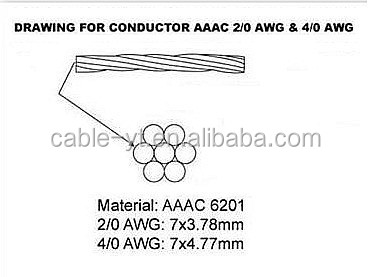

(AAAC) Conductor as per ASTM-B-399-1992

(AAAC) Conductor as per BS-3242-1970

(AAAC) Conductor IS: 398-IV-1994

(ACSR) as per ASTM-B-233-1992

(AAC) as per BS-215-1-1970

(AAC) as per IS-398-1: 1976

(AAC) as per ASTM-B-231-1990

(ACSR) as per IS: 398-II: 1976 & IS: 398-V: 1992

(ACSR) BS-215-II-1970

(AACSR) as per IEC-1089-1191

AAC(All aluminum conductor) are suited for overhead power line.

AAC All Aluminium Conductors

All-aluminium conductors are the most favored type for use in the construction of relatively short span distribution schemes and are in common use on lines for voltage up to 60 KV. Another frequent application for all-aluminium conductor is in flexible busbar connections. Although aluminium-to-copper connections can be made, it is better to use aluminium conductors for service connections, as various forms of covered cable being available for this purpose. The data sheets show the most common sizes of conductors but other sizes, to any

Recognized standards or customer specification can also be supplied. AAC insulated with XLPE or PVC can be supplied as per the customers' requirement.

ACSR Aluminium Conductor Steel Reinforced

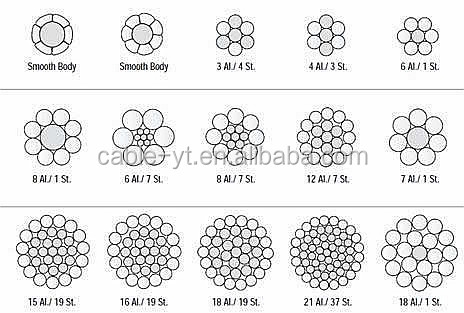

The mixed construction of ACSR makes it a very flexible medium from a design point of view. By varying the relative proportions of aluminium and steel the ideal conductor for any particular application can be produced. Generally, ACSR consists of a galvanized steel core of 1 wire, 7 wires or 19 wires surrounded

By concentric layers of aluminium wire. When a conductor with a high current carrying capacity and comparatively low strength is required, special constructions are available with a high aluminium content.

AAAC All Aluminium Alloy Conductors

This section deals with heat-treatable magnesium silicon type aluminium alloys to BS EN 50182, the electrical and mechanical properties of which all fall within the values s ested by Publication 104 of the international Electro technical Commission. Conductors to all other recognized specifications can also be supplied. The alloys referred to have higher strength but lower conductivity than pure aluminium. Being lighter, alloy conductors can sometimes be used to advantage in place of the more conventional ACSR;

Having lower breaking loads than the latter, their use becomes particularly favorable when ice and win loadings are low.

Model and Data

|

Technical characteristics of Al conductors / International standard-lEC1089 |

|||||||

|

|

|

|

|

|

|

|

|

|

Code Number |

Area mm 2 |

Number of wires |

Diameter |

LinearMass kg/km |

Rated Strength kN |

D.C Resistance Ω/km |

|

|

Wire mm |

Conductor mm |

||||||

|

10 |

10 |

7 |

1.35 |

4.05 |

27.4 |

1.95 |

2.8633 |

|

16 |

16 |

7 |

1.71 |

5.12 |

43.8 |

3.04 |

1.7896 |

|

25 |

25 |

7 |

2.13 |

6.40 |

68.4 |

4.50 |

1.1453 |

|

40 |

40 |

7 |

2.70 |

8.09 |

109.4 |

6.80 |

0.7158 |

|

63 |

63 |

7 |

3.39 |

10.20 |

172.3 |

10.39 |

0.4545 |

|

100 |

100 |

19 |

2.59 |

12.90 |

274.8 |

17.00 |

0.2877 |

|

125 |

125 |

19 |

2.89 |

14.50 |

343.6 |

21.25 |

0.2302 |

|

160 |

160 |

19 |

3.27 |

16.40 |

439.8 |

26.40 |

0.1798 |

|

200 |

200 |

19 |

3.66 |

18.30 |

549.7 |

32.00 |

0.1439 |

|

250 |

250 |

19 |

4.09 |

20.50 |

687.1 |

40.00 |

0.1151 |

|

315 |

315 |

37 |

3.29 |

23.00 |

867.9 |

51.97 |

0.0916 |

|

400 |

400 |

37 |

3.71 |

26.00 |

1102.0 |

64.00 |

0.0721 |

|

450 |

450 |

37 |

3.94 |

27.50 |

1239.8 |

72.00 |

0.0641 |

|

600 |

500 |

37 |

4.15 |

29.00 |

1377.6 |

80.00 |

0.0577 |

|

560 |

560 |

37 |

4.39 |

30.70 |

1542.9 |

89.60 |

0.0515 |

|

630 |

630 |

61 |

3.63 |

32.60 |

1738.3 |

100.80 |

0.0458 |

|

710 |

710 |

61 |

3.85 |

34.60 |

1959.1 |

113.60 |

0.0407 |

|

800 |

800 |

61 |

4.09 |

36.80 |

2207.4 |

128.00 |

0.0361 |

|

900 |

900 |

61 |

4.33 |

39.00 |

2483.3 |

144.00 |

0.0321 |

|

1000 |

1000 |

61 |

4.57 |

41.10 |

2759.2 |

160.00 |

0.0289 |

|

1120 |

1120 |

91 |

3.96 |

43.50 |

3093.5 |

179.20 |

0.0258 |

|

1250 |

1250 |

91 |

4.18 |

46.00 |

3452.6 |

200.00 |

0.0231 |

|

1400 |

1400 |

91 |

4.43 |

48.70 |

3866.9 |

224.00 |

0.0207 |

|

1500 |

1500 |

91 |

4.58 |

50.40 |

4143.1 |

240.00 |

0.0193 |