| Model: | - |

|---|---|

| Brand: | Spark |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Alloy |

| Label: | - |

| Price: |

US $25

/ pc

|

| Min. Order: | 10 pc |

| Last Online:28 Sep, 2022 |

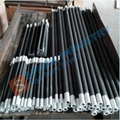

MoSi2 heating element can usually make use of furnace temperature from 1300C to 1900C. It is extensively used in the industries of metallurgy, glass, ceramic refractory, crystal electronic device, industrial furnace manufacturer etc. It is an essential ideal element when the products are sintering in the high temperature.

MoSi2 heating element is used in the high temperature under oxidizing atmosphere. It will form the SiO2 film which can keep the element from being melted. During the oxidizing process, the SiO2 protecting film is formed again when the element continues to be used. The MoSi2 heating element must not be used in the temperaturebetween 400C and 700C for a long time, otherwise the element will be cremated under the strong oxidizing function in the low temperature.

Common properties of hot-pressed MoSi2 are illustrated in Table 1.

Table 1. Typical physical and mechanical properties of molybdenum disilicide

| Property | Value |

| Density (g.cm-3) | 6.29 |

| Melting Point (°C) | 2230 |

| Young’s Modulus (GPa) | 430 |

| Bend Strength (MPa) | 250 |

| Fracture Toughness K1C (MPa.m0.5) | 3 |

| Hardness (GPa) | 9 |

| Resistivity (ohm.cm) (at room temp) | 3.5 x10-7 |

| Resistivity (ohm.cm) (at 1700 °C) | 4.0 x10-6

|

| Payment Terms: | TT / LC / PayPal |

|---|---|