| Model: | - |

|---|---|

| Brand: | Spark |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Alloy |

| Label: | - |

| Price: |

US $20

/ pc

|

| Min. Order: | 10 pc |

| Last Online:28 Sep, 2022 |

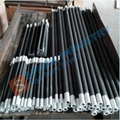

Made of high density recrystallized silicon carbide, these multiple leg SiC bars use the same hot zone and cold end material as the RR type SiC bars and offer a configuration that allows the electrical connections to be made at one end. The low resistance terminal ends allow for cool operation. The LRE (low resistance ends) have a high (15:1) electrical resistance ratio to the hot zone section. The first several inches of the cold ends are metallized with aluminum to provide a low electrical resistance contact surface. The electrical connections are made using flat aluminum braids held in compression to the circumference by a stainless steel spring clamp.

Advantages:

1. Withstands as high as 1500 (surface temperature).

2. Generates high heat output per unit surface area, approximately 5-10 times the output of Nichrome wire.

3. High strength and excellent shock resistance.

4. Heat source is free of noise and air pollution.

When you place order, please tell us following data:

IFC-GD type elements are made from high-density, high-purity silicon carbide, which is the most popular type of economical heating element capable of operating under hot and rigorous environments.

Specification and Range of Resistance:

|

Diameter |

Length of hot zone |

Length of cold zone |

Overall length |

Range of resistance |

|---|---|---|---|---|

| 8mm | 100-300mm | 60-200mm | 240-700mm | 2.1-8.6 ohms |

| 12mm | 100-400mm | 100-350mm | 300-1100mm | 0.8-5.8 ohms |

| 14mm | 100-500mm | 150-350mm | 400-1200 | 0.7-5.6 ohms |

| 16mm | 200-600mm | 200-350mm | 600-1300 | 0.7-4.4 ohms |

| 18mm | 200-800mm | 200-400mm | 600-1600 | 0.7-5.8 ohms |

| 20mm | 200-800mm | 250-600mm | 700-2000mm | 0.6-6.0 ohms |

| 25mm | 200-1200mm | 250-700mm | 700-2600mm | 0.4-5.0 ohms |

| 30mm | 300-2000mm | 250-800mm | 800-3600mm | 0.4-4.0 ohms |

| 35mm | 400-2000mm | 250-800mm | 900-3600mm | 0.5-3.6 ohms |

| 40mm | 500-2700mm | 250-800mm | 1000-4300mm | 0.5-3.4 ohms |

| 45mm | 500-3000mm | 250-750mm | 1000-4500mm | 0.3-3.0 ohms |

| 50mm | 600-2500mm | 300-750mm | 1200-4000mm | 0.3-2.5 ohms |

| 54mm | 600-2500mm | 300-750mm | 1200-4000mm | 0.3-3.0 ohms |

ANTI-OXIDANT PROPERTY OF ELEMENTS:

The silicon carbide heating element is a kind of non-metal high temperature electric heating element. It is made of selected super quality green silicon carbide as main material, which is made into blank, silicided under high temperature and re-crystallized. Compared with metal electric heating element, this kind of element is characterized by high-applied temperature, anti- oxidization, anti- corrosion, long service life, little deformation, easy installation and maintenance. Therefore, it is widely used in various high temperature electric furnaces and other electric heating devices, such as in the industries of magnet, ceramics, powder metallurgy, glass and machinery,etc.

We adopt new production process of cold ends, so our Sic heating elements have excellent specific rate of heat zone resistance and cold end resistance, saving energy, long life, avoiding over-temperature of cold ends to damage the furnace body.

| Payment Terms: | TT / LC / PayPal |

|---|---|