| Model: | - |

|---|---|

| Brand: | Spark |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Alloy |

| Label: | - |

| Price: |

US $25

/ pc

|

| Min. Order: | 10 pc |

| Last Online:28 Sep, 2022 |

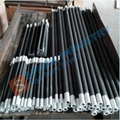

Furnace Heating Element:

1. High temperature for various electric furnaces.

2. Long life combined with ease of replacing failed elements.

3. Can be used continuously or intermittently.

4. New and old elements can be connected in series.

5. High power concentration may be applied.

MoSi2 Heater Advantages:

A. It has anti- oxidation and automatic repair.

B. function and can be used continually in oxidative atmosphere.

C. We are using thermal processing in shape,which maintains a very good high-temperature tenacity and plasticity of the basic materials.

D. the cold and hot end welding aspect, it uses special joint technology to take shape.

E. The product has high density that greatly improves the conductivity of the product.

F. good surface quality, high mechanical strength and toughness.

Application:

Both 1700, 1800C MoSi2 electric heaters for muffle furnace are extensively used in the industries of metallurgy, glass, ceramic refractory, crystal electronic device, industrial furnace manufacture, etc. It is an essential ideal element when the products are sintering in the high temperature.

Attention:

MoSi2 elements can not be used in 400 to 700 °C for a long time, otherwise, it will be powered and damaged due to strong oxidizing action in low temperature.

| Payment Terms: | TT / LC / PayPal |

|---|---|