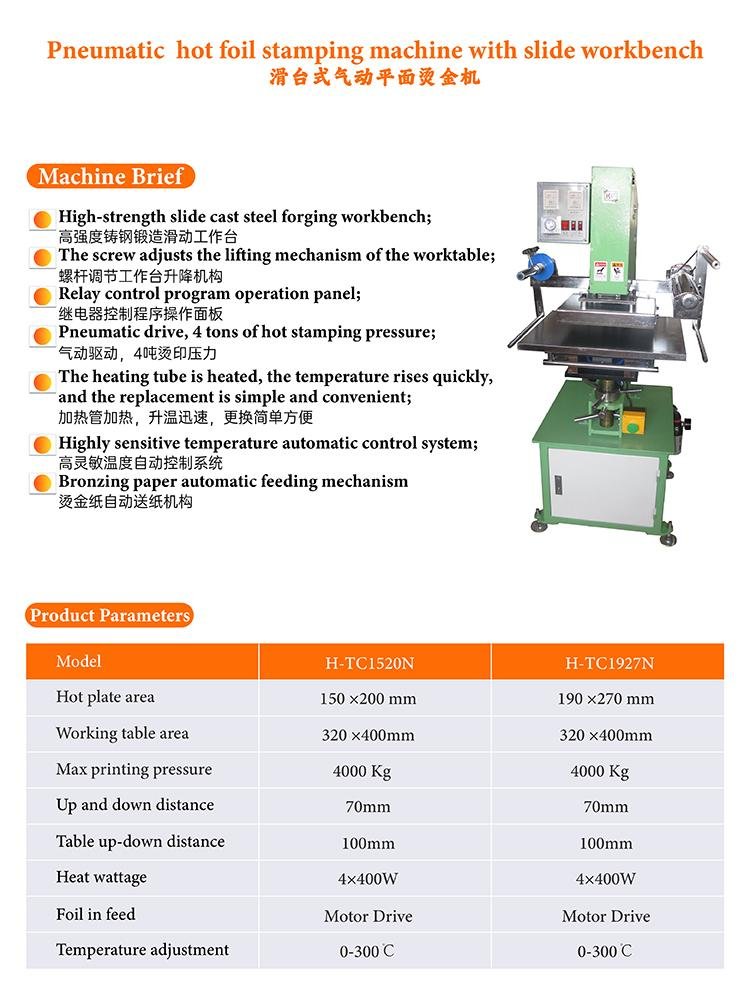

| Model: | H-TC1927N |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | hot stamping machine , Photo album , book gilding machine |

| Price: |

US $2294

/ pic

|

| Min. Order: | 1 pic |

Product Description

The main action of the hot stamping machine is that the hot plate moves up and down. When the hot plate touches the product or the workbench, a strong pressure is formed. For the operator, the potential risk may cause personal injury. The safety requirements of hot stamping machines are higher than those of pad printing machines and screen printing machines. A widely used design is to install a workbench that can automatically enter and exit the workbench. The hot stamping machine with automatic worktable entry and exit can only be regarded as a balance between safety and cost, so it is very popular among users. When users have further requirements for safety, measures such as installing safety gratings and safety covers will also be considered.

|

Pneumatic Movement-table hot stamping Machine//Structure |

||

|

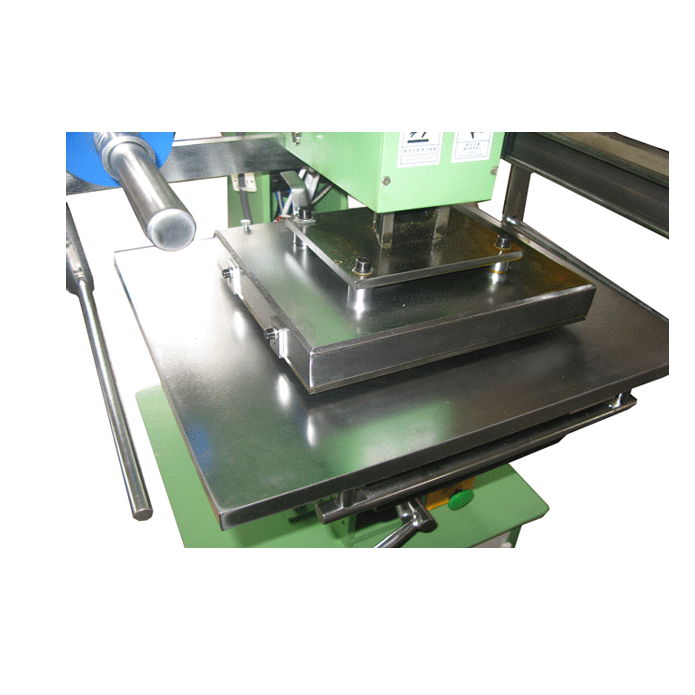

Working table |

High strength Steel plate , size:320*400mm.automatically in-out |

|

|

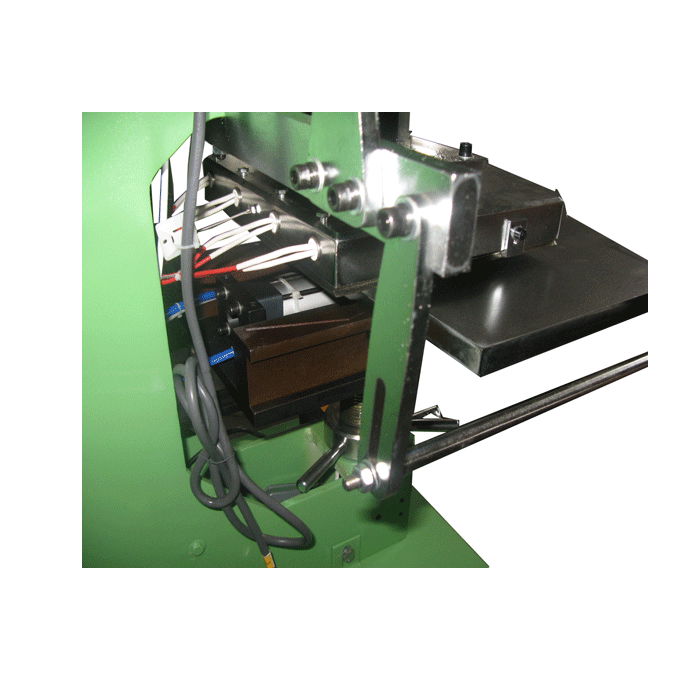

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Pneumatic movement-table hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Pneumatic movement-table hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC1520N |

H-TC2129N |

|

|

|

|

H-TC1927N |

H-TC3025N |

|

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Pneumatic movement-table hot stamping machine //Advantage |

||

|

Function |

|

|

| Application: | The main action of the hot stamping machine is that the hot plate moves up and down. When the hot plate touches the product or the workbench, a strong pressure is formed. For the operator, the potential risk may cause personal injury. The safety requirements of hot stamping machines are higher than those of pad printing machines and screen printing machines. A widely used design is to install a workbench that can automatically enter and exit the workbench. The hot stamping machine with automatic worktable entry and exit can only be regarded as a balance between safety and cost, so it is very popular among users. When users have further requirements for safety, measures such as installing safety gratings and safety covers will also be considered. |

|---|---|

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 30 Oct, 2024 |

Related Products of this Company

-

Manual Hot stamping machine-HM-TC3030LT

US $1350

-

Easy operation hot selling Manual Hot

US $1397

-

Tabletop UV Curing Unit

US $1250

-

IR Drying tunnel

US $2280

-

Stalility hot stamping

US $8970

-

Oblique arm high quality Screen

US $5758

-

Servo Cylinder hot stamping

US $12880

-

Spot UV Flat UV Curing Machine for paper

US $2129

-

Sublimation paper screen printing

US $5300

-

light fittings Hot stamping

US $2441