| Model: | 100 |

|---|---|

| Brand: | Jiangxi national porcelain |

| Origin: | Made In China |

| Category: | Industrial Supplies / Environment Protection Facilities / Air Purifier |

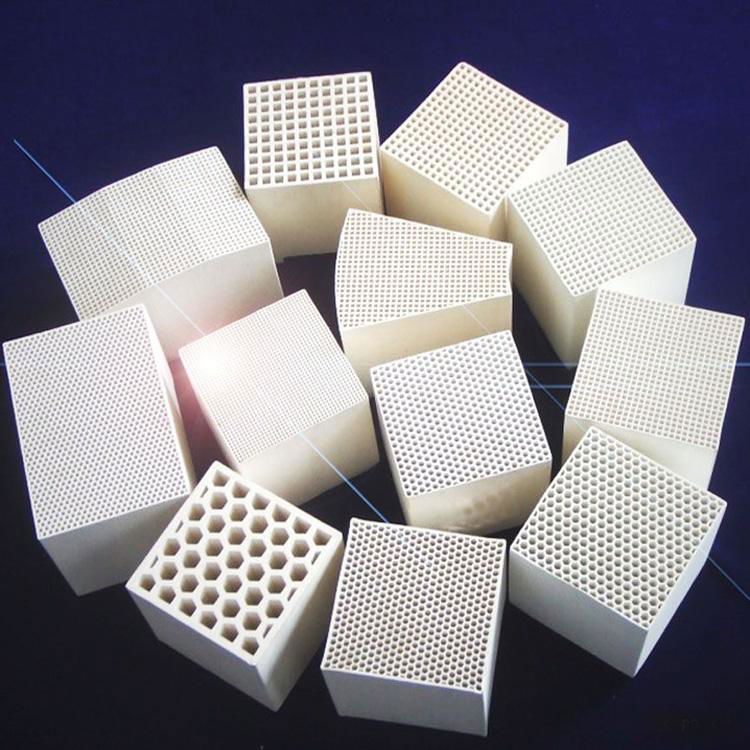

| Label: | honeycomb ceramics , Honeycomb ceramic re , heat accumulator |

| Price: |

¥35

/ pc

|

| Min. Order: | 1000 pc |

Product Description

The regenerative high temperature air combustion technology (HTAC) has the dual function of energy saving and environmental protection. Compared with the traditional combustion technology, the fuel 20-50% is saved by more than 20%, the emission of NOx is reduced by more than 40%, and the production efficiency is greatly improved. As one of the key components, honeycomb regenerator has the advantages of large unit volume heat transfer area, fast heat transfer, small air flow resistance, shallow heat transfer depth and high thermal efficiency. Square hole, round hole, six hole and so on all kinds of pass and plane, inclined plane, single slot, double groove all kinds of wall shape. According to the characteristics and environment of the industrial furnace in our country, the technicians of our company are bold and innovative, and take the lead in the manufacture of honeycomb regenerator, baffle brick and heat storage ball with high temperature fused corundum and other high purity materials over 2000 C. This synthetic material has the advantages of high refractoriness, high softening temperature, good slag resistance, good thermal shock stability, fast heat conduction, good resistance to scour, great capacity and high thermal capacity, and the service life reaches the level of the same kind of foreign products. In addition, the catalytic combustion of CO and HC compounds in the flue gas at about 600 degrees centigrade can be used to further improve the recovery of waste heat and reduce the emission of polluted gas, which is now being extended in a large area.

The function of the honeycomb ceramic regenerator product:

First, reduce the heat loss of exhaust gas, maximize the utilization rate of fuel and reduce unit energy consumption.

(2) improving the theoretical combustion temperature, improving the combustion conditions, meeting the high temperature requirements of the thermal equipment, expanding the application range of low calorific value fuel, especially the application range of the blast furnace, and improving the utilization ratio of the calorific value of the fuel;

(3) improving the heat exchange conditions of the furnace, increasing the output of the equipment and the quality of the products, and reducing the investment of the equipment;

4. Reduce exhaust emissions and harmful gas emissions of thermal equipment units, reduce air pollution and improve the environment.

Regenerator material: high aluminum, compact high aluminum, cordierite, compact cordierite, mullite, corundum mullite, etc.

Specifications are: 100x100x100, 100x150x150, 150x150x150, 150x150x300mm and so on, and can be produced according to customer needs.

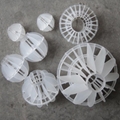

The holes are square, rectangle, circle, triangle, hexagon and so on.

| Payment Terms: | TT |

|---|---|