| Model: | 100 |

|---|---|

| Brand: | JiangxiGuoci |

| Origin: | Made In China |

| Category: | Industrial Supplies / Environment Protection Facilities / Air Purifier |

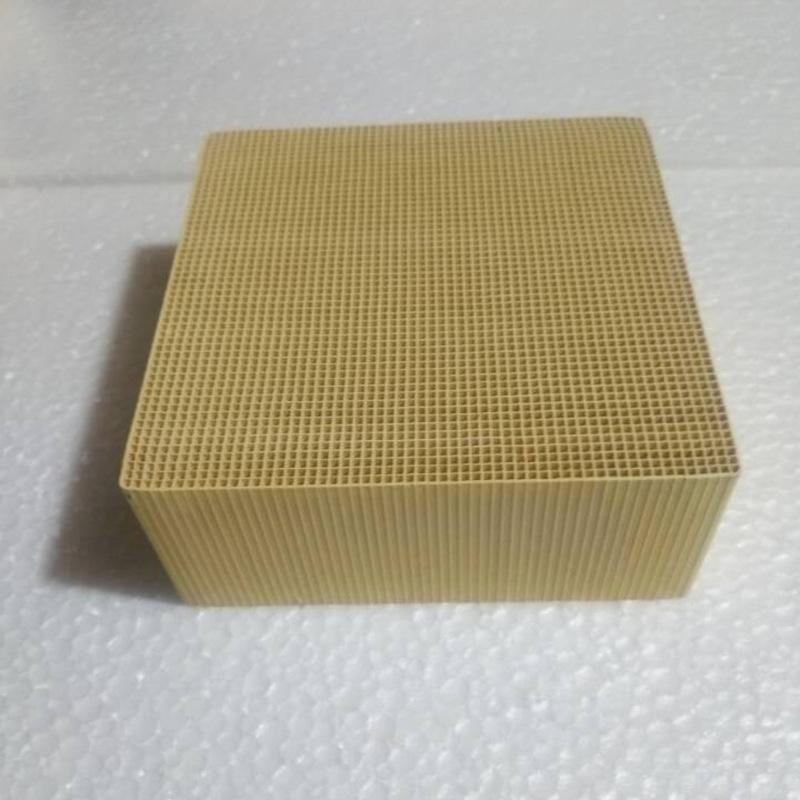

| Label: | Catalyst carrier , Honeycomb ceramics , Catalyzer |

| Price: |

¥150

/ pc

|

| Min. Order: | 1000 pc |

Product Description

The GC-V01 type VOC organic waste gas purification catalyst is made of cordierite honeycomb ceramic as the carrier, using the unique coating material, the active component of precious metal Pd and Pt, with high catalytic activity, good thermal stability, long service life, small air flow resistance, high strength and so on. The exhaust gas purification catalyst can be widely applied to organic waste gas treatment in industries such as chemical industry, paint, enameled wire, coating, ovens and other industries. (attached to GC-V01-A product photo) 4. low temperature catalytic combustion process characteristics

(1) when the ignition temperature is low and reaches a certain concentration, it does not need external energy supply to operate and save energy.

2. Combustion temperature is low, flameless combustion, no NOx compounds are produced.

(3) the combustion rate is fast, the combustion is complete, and no toxic carcinogens such as benzopyrene and dioxin are produced.

(4) the combustion products are harmless CO2 and H2O, and there are no two pollutants such as solid waste, sewage, waste solvent and exhaust gas.

5. The processing efficiency is very high, and the rate of complete compliance is much higher than that of other treatments.

The process equipment is simple, the technology is mature, the equipment and transportation cost is low, and the unit waste gas treatment cost is low;

Reasonable design of equipment, safe and reliable operation, stable performance, PLC fully automatic operation, no need for personal maintenance;

It is suitable for all kinds of complex and odorous waste gas treatment in high and low concentration industries.

The equipment has compact structure and small area.

Precautions and maintenance measures for the use of 5. catalyst

Attention: in the low temperature state, a large number of organic matter enters the catalytic bed, causing the catalyst "suffocating" and causing temporary inactivation; sulfur, phosphorus, arsenic, halogen compounds and heavy metal compounds will react with the active component, resulting in the permanent deactivation of the catalyst; dust, charcoal, and high boiling stickies are attached to the surface of the catalyst. Covering the active site of the catalyst leads to the loss of catalysis, and the catalyst carrier and the active component are agglomerated or sintered at high temperature, resulting in a large reduction in the number of active digits and inactivation.

Maintenance measures: low temperature "suffocating": before the normal operation, the catalytic bed should be preheated in the fresh air to the reaction temperature first, then the organic waste gas can be passed through; sulphur and other toxic substances exist: removal of such substances by pretreatment means or the selection of the catalyst with corresponding resistance; dust, charcoal, high boiling stickiness: good Pretreatment: over temperature: when the catalyst bed temperature exceeds 600 degrees, the system will stop running or use fresh air to dilute and cool down.

6. application fields

Organic waste gas is a common pollutant discharged from petrochemical industry, light industry, plastic, printing, coating, spray painting and other industries. The waste gases often contain hydrocarbons and oxygen - containing organic compounds. If the waste gas is discharged directly into the atmosphere without treatment, it will cause serious pollution to the environment and endanger human health.

Nowadays, waste gas treatment technology includes combustion, condensation, adsorption and membrane treatment. In addition to combustion technology, other treatment methods are mainly suitable for occasions where the species is single and the exhaust gas condition is relatively stable, and the applicable working conditions are all small. However, most industrial waste gases have complex species, large fluctuation of working conditions and low recovery value. Suitable combustion technology is adopted for this type of tail gas. In addition, compared with the conventional thermal incineration technology, low temperature catalytic combustion technology has the advantages of energy saving, environmental protection and economy.

As a high performance low temperature catalytic oxidation technology, the catalytic combustion treatment technology can be applied to the treatment of most combustible organic waste gases, and the range of concentration is wide (200 ~ 10000mg/m3). The low concentration below 1000mg/m3 needs to be concentrated, and the concentration above 10000mg/m3 needs to be diluted. In particular, when the organic matter in the tail gas is not suitable for recovery or recovery, the catalytic combustion technology can be treated efficiently and low cost, and the concentration of the tail gas can be reduced to less than 100ppm after purification.

| Payment Terms: | TT |

|---|---|