| Model: | SANHE-FOAM001 |

|---|---|

| Brand: | SANHE |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-metallic Mineral Products |

| Label: | ceramic filter , ceramic , Foam Ceramic |

| Price: |

US $1

/ pc

|

| Min. Order: | 500 pc |

Product Description

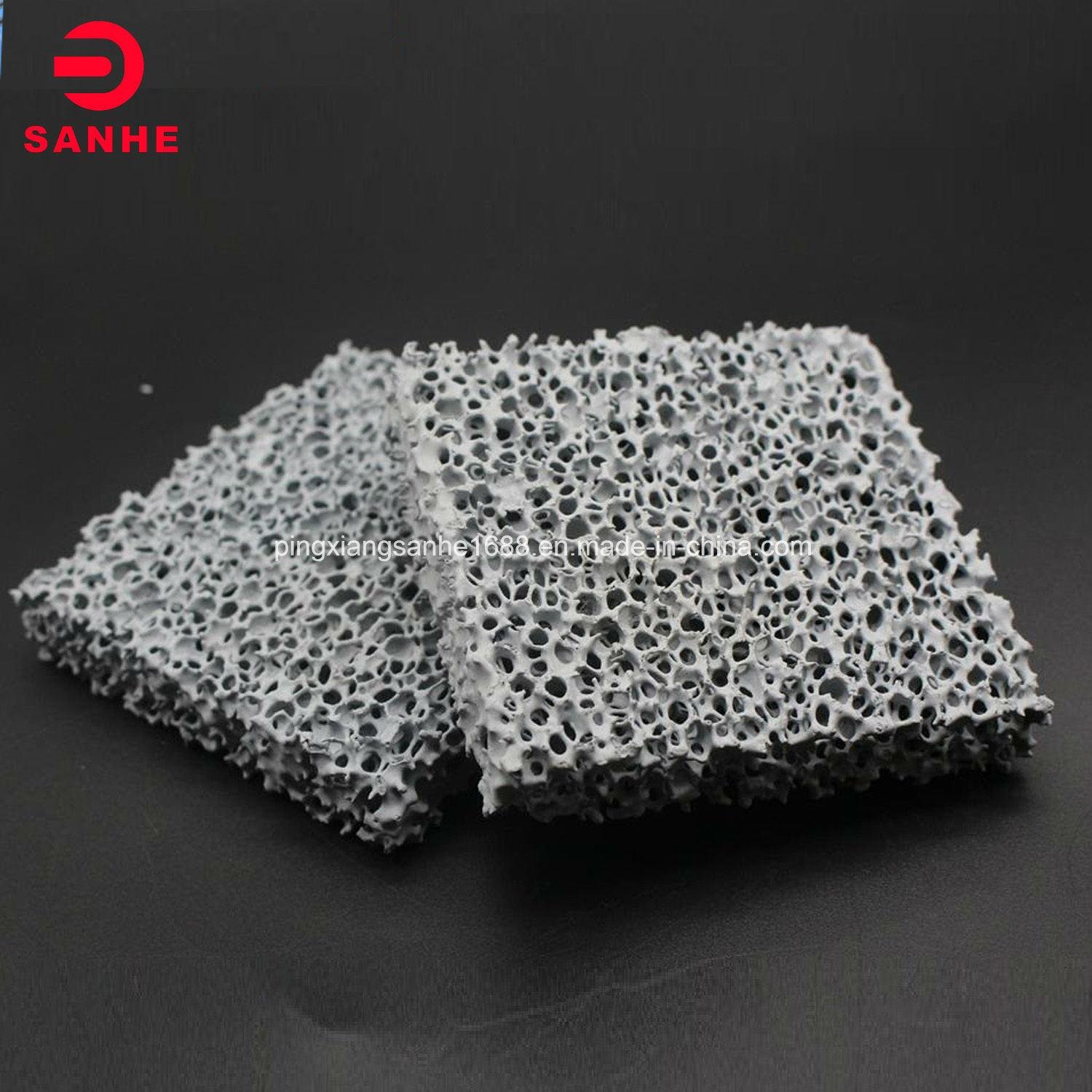

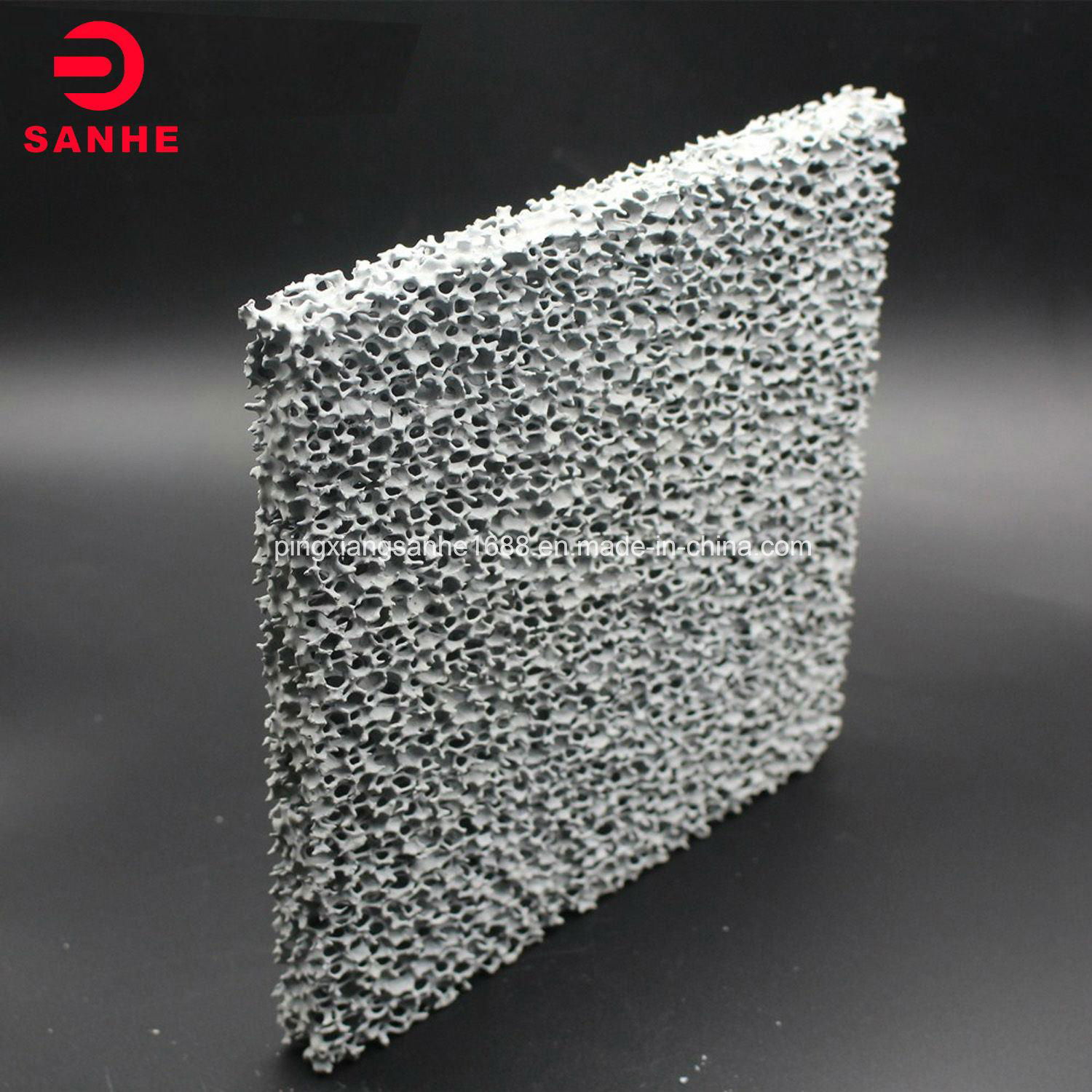

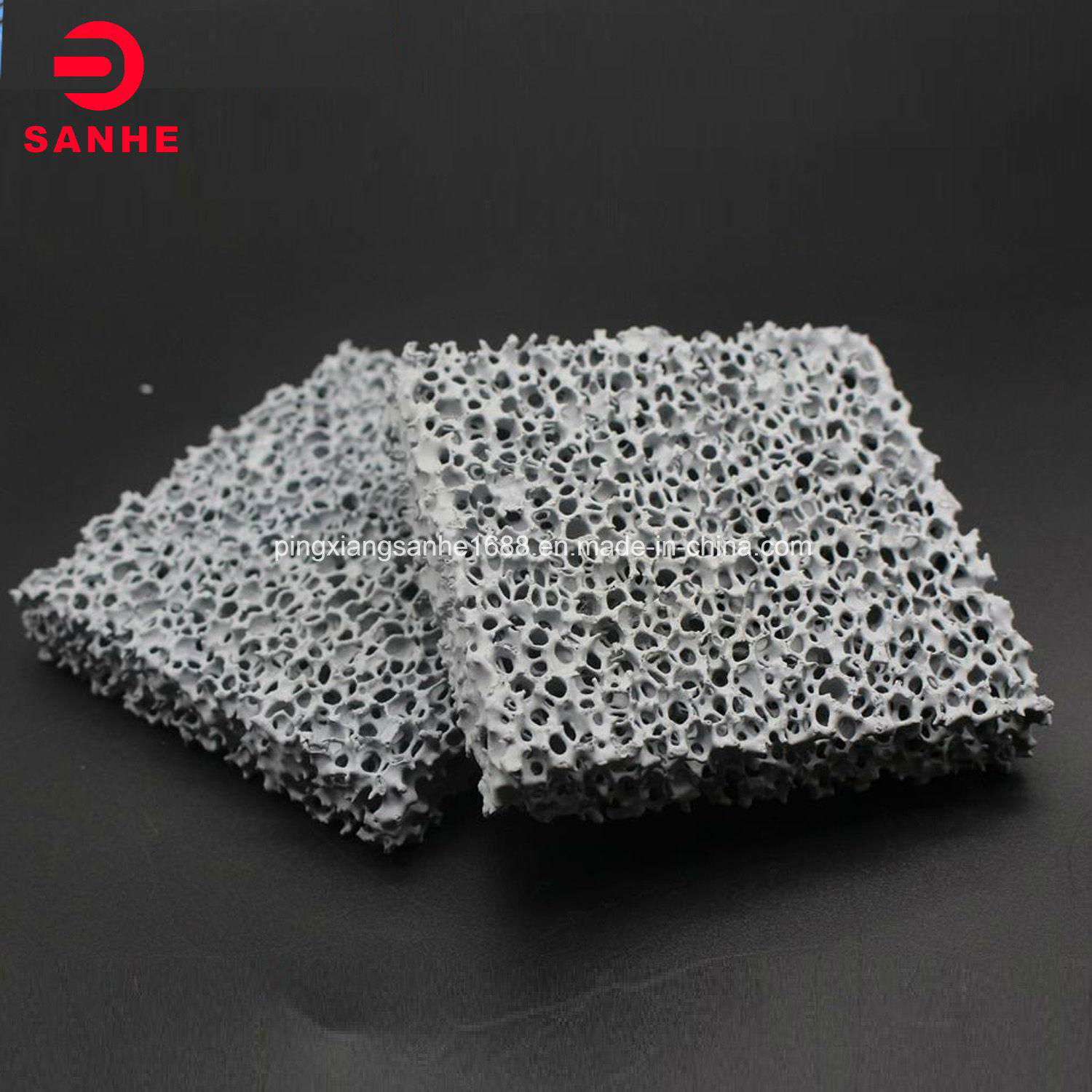

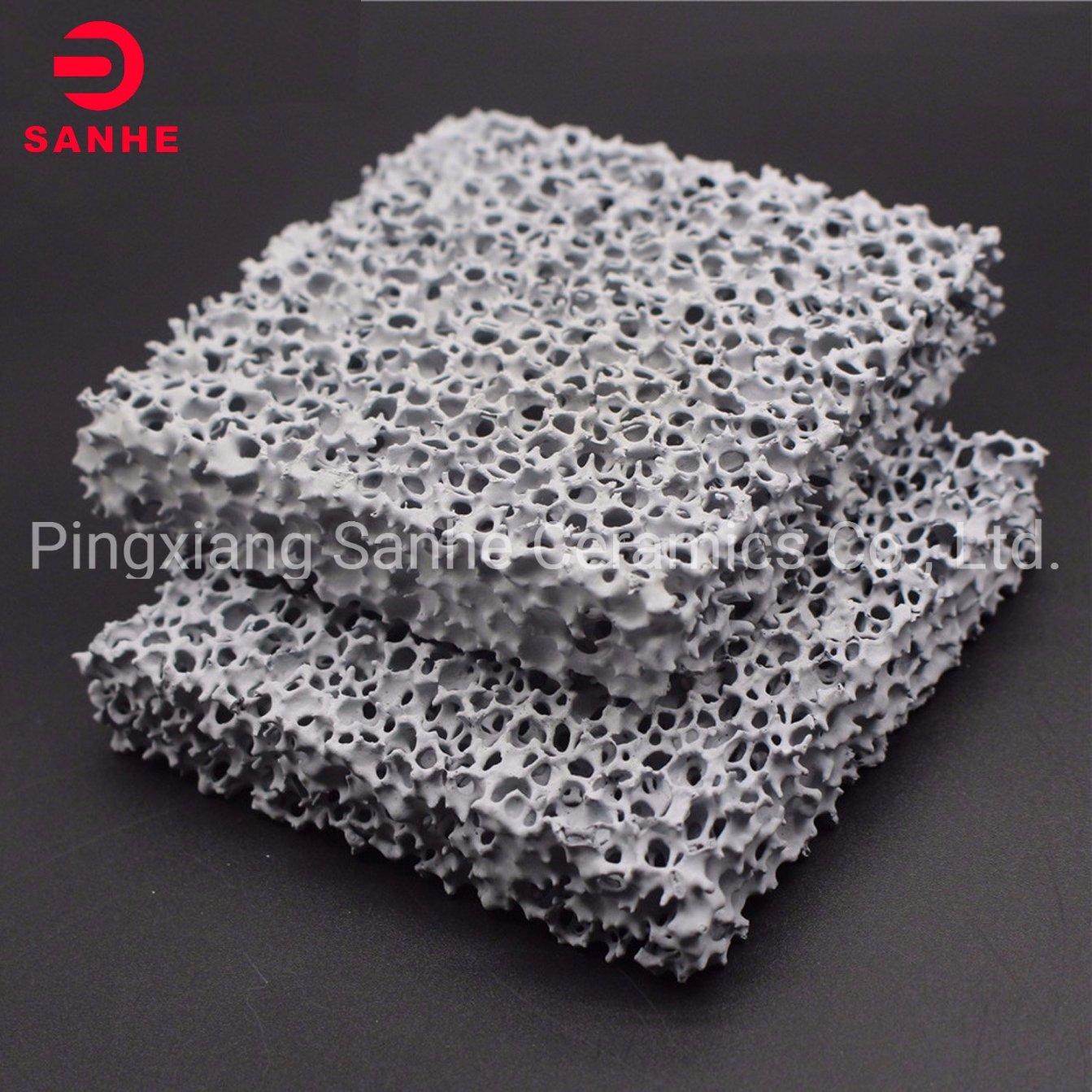

The basic materials of the ceramic foam filter are three kinds of silicon carbide, zirconium oxide and aluminum oxide.

The basic material of the zirconia foam ceramic filter is zirconia ZrO2. The zirconia filter has a heat resistance temperature higher than about 1760 ° C and has a very high strength and an excellent high temperature impact force.

Cast steel parts are widely used in applications that require high strength and elongation requirements. Therefore, steel castings are very sensitive to defects caused by impurities. The excellent characteristics of the zirconia foam ceramic filter can effectively remove the impurities that ultimately lead to product quality defects. The impurities are mainly composed of non-metal particles, slag, and refractory fragments, which improve the surface quality and mechanical properties of the casting and reduce the scrap rate.

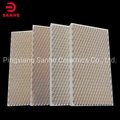

Characteristics of silicon carbide foam ceramic filter:

Silicon carbide has excellent strength and high temperature impact resistance and chemical corrosion. It can withstand high temperatures up to about 1560 °C. They are therefore suitable for the casting of all copper alloys and cast iron. The ceramic foam filter can significantly improve the quality of cast iron parts and reduce the scrap rate. It can also be used in the continuous casting and rolling process, and can be manufactured to all standard sizes and different thicknesses.

Silicon Carbide Ceramic Foam Filters mainly for filtration of cast iron and non-ferrous alloys. With their excellent resistance to attack and corrosion from molten iron liquid, they can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

SiC Ceramic Foam Filters (CFF-SC) is available in all standard dimensions and different thickness. The most common porosities are PPI 10, 20 and 30; higher porosities are available upon request. Custom-made cut-to-size filters are also possible.

SiC Ceramic Foam Filters (CFF-SC) common sizes in Round shape:

40x11mm, 40x15mm, 50x15mm, 50x20mm, 60x22mm,

70x22mm, 80x22mm , 90x22mm,100x22mm, 305x25mm

SiC Ceramic Foam Filters (CFF-SC) common sizes in Square shape:

40x40x11mm, 40x40x15mm, 50x50x22mm, 75x75x22mm, 50x75x22mm,

100x75x22mm, 100x100x22mm, 55x55x15mm, 150x150x22mm

Physical Properties for SiC Ceramic Foam Filters (CFF-SC):

|

Working Temperature |

≤1540°C |

|

Porosity |

80~90% |

|

Compression Strength

|

≥1.0Mpa |

|

Volume Density |

0.3-0.5g/cm3 |

|

Thermal Shock Resistance |

1200°C---room temperature 3 times |

|

Application |

cast iron, cast copper, cast bronze, cast brass

|

Chemical Composition for SiC Ceramic Foam Filters(CFF-SC):

|

Al2O3 |

SiC |

SiO2 |

Fe2O3 |

|

≤28.00% |

≥62.00% |

≤10.00% |

≤0.50% |

About us

Pingxiang Sanhe Ceramics Co., Ltd. lies in Pingxiang city, Jiangxi province, which belongs to one of the five ceramic production export bases in China. The company is a private technology share ceramics manufacturing enterprise founded in 2004. We specialize in honeycomb ceramic plates, honeycomb ceramics heat accumulators, honeycomb ceramic honeycomb substrates, ceramic foam filter and other producing energy conservation and environmental protection series ceramic products.

Sanhe Ceramics has successfully passed all kinds of certifications such as ISO9001 ISO14001, OHSAS18001 and so on, as well as established perfect quality control system and quality assessment system. Our company has been strictly controlled the whole manufactring system from production planning, processing control to maintenance of equipment as well as from raw material warehousing to quality test of finished products, We offer Stable and qualified products to customers from all over the world. Superiority, uniformity and environmental friendliness of its quality has gained great reputation among all customers. We obey the research and development design production idea of specialization, standardization, internationalization and technicalization, striving to make the products of the company more perfect with stronger customer base.

Sanhe ceramics Co.,Ltd keeps the faith of "First impression is the last impression" and provides the best quality and comfortable service to all the buyers, No matter the deal is big or small, we are warmly welcome your coorperation. Any inquiries pls contact with us!

Member Information

| Pingxiang Sanhe Ceramics Co., Ltd | |

|---|---|

| Country/Region: | Jiang Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 18507999079 |

| Contact: | Vicky (Sales Manager) |

| Last Online: | 06 Nov, 2023 |

Related Products of this Company

-

Alumina Foam Ceramics for Aluminium

US $0.5

-

Round Shape Alumina Ceramic Foam Filter

US $0.5

-

Rto Honeycomb Ceramic Regenerator for

US $1200

-

Refractory Honeycomb Ceramic Brick for

US $1200

-

Zirconia Foam Ceramic for Steel Casting

US $2

-

Cordierite Round Honeycomb Burner

US $0.5

-

Square Shape Carbide Silicon Honeycomb

US $3

-

Infrared Honeycomb Ceramic Burner Plate

US $0.5

-

Ceramic Plate for Gas Cooker BBQ Grill

US $0.3

-

Cordierite Mullite Ceramic Honeycomb

US $0.5