| Model: | SANHE-FOAM-ZrO2 |

|---|---|

| Brand: | SANHE |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-metallic Mineral Products |

| Label: | Foamed Ceramic , ceramic filter , industrial ceramics |

| Price: |

US $2

/ pc

|

| Min. Order: | 500 pc |

Product Description

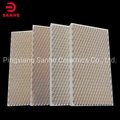

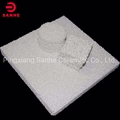

Ceramic foam have different materials such as alumina, silicon carbide, zirconia and others.

Ceramic foam filter is a kind of porous material with high temperature characteristics. Its pore size ranges from nanometer to micron, its porosity is between 20% and 95%, and its operating temperature is room temperature 1600°C. Due to its high porosity, high specific surface area, thermal shock resistance, high temperature resistance, chemical resistance, good mechanical strength, good filtration and adsorption properties, Ceramic Foam Filter can be widely used in heat exchange materials, cloth gas materials, automobile exhaust equipment, purification metallurgy, industrial filtration of molten metal, thermal energy recovery, light industrial spraying industry, industrial wastewater treatment, thermal insulation material, chemical Honeycomb Substrate. Ceramic Foam Filter have been used in automotive catalytic converters for a long time. The deodorant ceramic foam filter catalyst enables the catalytic combustion of organic solvents and malodorous gases in the waste water to achieve the purpose of deodorization and purification. The use of high-permeability Ceramic Foam Filter that are resistant to high temperatures and have sufficient thermal shock resistance can effectively remove high-temperature dust gases. In the process of urban sewage treatment, Ceramic Foam Filter also become one material for aeration treatment in urban sewage treatment.

ZrO2 Ceramic Foam Filter:

Zirconia ceramic foam filter is applied to purge solution steel, steel alloy and stainless steel, it can endure require of technology of steel and get rid of foreign matter and materials of corroded model. Zirconia ceramic foam filter can also drop turulent and reduce twice oxided foreign matter. Zirconia ceramic foam filter is designed for the filtration of molten steel, alloy steel and especially for high quality steel alloys casting temperature up to 1700℃, which have high porosity(76%-82%), high thermal shock resistance and large specific surface.

Advantages:

Ceramic foam filters help to enhanced quality of castings and reduce cost.

*Special 3D structure to reduce turbulence of flowing molten metal

*Reduce defective rate of castings

*Improved mechanical properties of castings

*Improved precision of demensions and shapes of castings

*Reduced costs of machining perations

*Simplify pouring systems and increase utilization ratio of mold

Technical parameters:

|

Material |

Zirconia |

|

Color |

Yellow |

|

Pore Density |

8-60ppi |

|

Porosity |

80-90% |

|

Refractoriness |

≤1700°C |

|

Bending Strength |

>1.0Mpa |

|

Compression Strength |

>1.2Mpa |

|

Volume-weight |

0.9-1.5 g/cm3 |

|

Thermal shock resistance |

6times/1100°C |

|

Application |

High melting point metal alloys like Steel,Alloy Steel,Stainless Steel etc |

Specification for Steel Casting:

|

Dimensions (mm) |

Zirconia Foam Filter |

|

|

Pouring Rate(kg) |

Filtration Capacity(kg) |

|

|

50×50×22 |

3~5 |

30 |

|

50×75×22 |

4~6 |

40 |

|

75×75×22 |

7~12 |

60 |

|

75×100×22 |

8~15 |

80 |

|

100×100×22 |

14~20 |

100 |

|

Dia 50×22 |

2~6 |

18 |

|

Dia 80×22 |

6~10 |

50 |

|

Dia 90×22 |

8~16 |

70 |

About us

Pingxiang Sanhe Ceramics Co., Ltd. lies in Pingxiang city, Jiangxi province, which belongs to one of the five ceramic production export bases in China. The company is a private technology share ceramics manufacturing enterprise founded in 2004. We specialize in honeycomb ceramic plates, honeycomb ceramics heat accumulators, honeycomb ceramic honeycomb substrates, ceramic foam filter and other producing energy conservation and environmental protection series ceramic products.

Sanhe Ceramics has successfully passed all kinds of certifications such as ISO9001 ISO14001, OHSAS18001 and so on, as well as established perfect quality control system and quality assessment system. Our company has been strictly controlled the whole manufactring system from production planning, processing control to maintenance of equipment as well as from raw material warehousing to quality test of finished products, We offer Stable and qualified products to customers from all over the world. Superiority, uniformity and environmental friendliness of its quality has gained great reputation among all customers. We obey the research and development design production idea of specialization, standardization, internationalization and technicalization, striving to make the products of the company more perfect with stronger customer base.

Sanhe ceramics Co.,Ltd keeps the faith of "First impression is the last impression" and provides the best quality and comfortable service to all the buyers, No matter the deal is big or small, we are warmly welcome your coorperation. Any inquiries pls contact with us!

Member Information

| Pingxiang Sanhe Ceramics Co., Ltd | |

|---|---|

| Country/Region: | Jiang Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 18507999079 |

| Contact: | Vicky (Sales Manager) |

| Last Online: | 06 Nov, 2023 |

Related Products of this Company

-

Rto Honeycomb Ceramic Regenerator for

US $1200

-

Square Shape Carbide Silicon Honeycomb

US $3

-

Ceramic Plate for Gas Cooker BBQ Grill

US $0.3

-

Alumina Foam Ceramics for Aluminium

US $0.5

-

SiC Foam Ceramics Foundry Filter for

US $1

-

BBQ Industrial Infrared Gas Burners Use

US $0.5

-

Round Shape Alumina Ceramic Foam Filter

US $0.5

-

Infrared Honeycomb Ceramic Burner Plate

US $0.5

-

Refractory Honeycomb Ceramic Brick for

US $1200

-

Manufacturer Cheap Honeycomb Ceramic as

US $20