| Model: | HC1010B |

|---|---|

| Brand: | HUACHUANG |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Cleaning Machine |

| Label: | Box type manual sand , Manual sand blasting , Environmental protec |

| Price: |

US $1995

/ pc

|

| Min. Order: | 1 pc |

Product Description

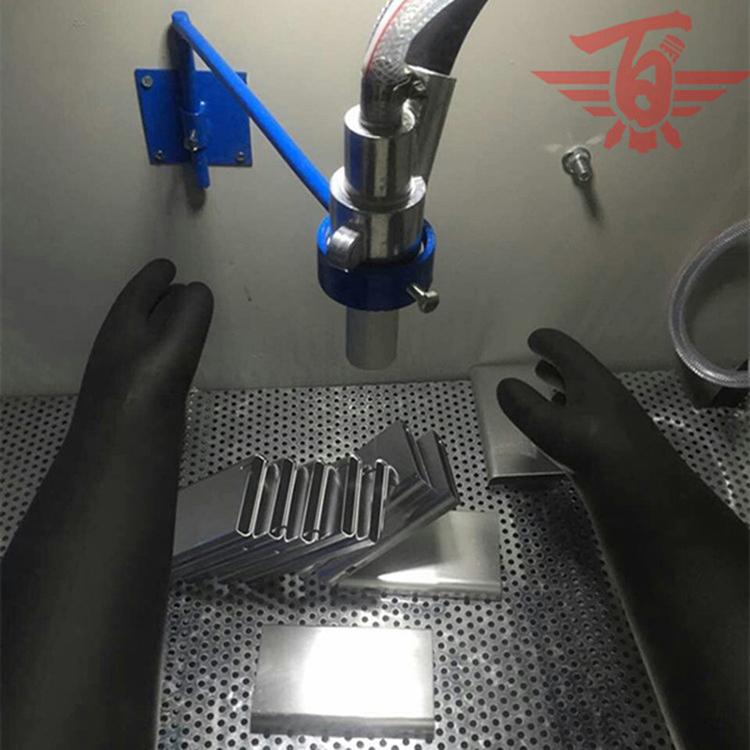

Descaling, deburring and attaching manual sandblasting machine

This equipment has the advantages of simple and reliable structure, small floor area, stable quality, convenient operation, good processing efficiency, low energy consumption, fast sand blasting efficiency, deep impact point, low failure rate and good environmental protection effect. It is suitable for rapid sand blasting processing of small and medium-sized general workpieces and high hardness workpieces。

Selling point:

1. Equipped with two-stage separator, abrasive wear is small.

2. Using Jiuzhou famous brand core fan, the dust separation effect is good.

3. Polyester fiber coated filter element is adopted, and the machine has no dust.

4. The nozzle uses wear-resistant boron carbide nozzle, which has a long service time, large sand output and full and even sand feeling.

5. The sandblasting pressure can be adjusted.

6. Automatic recovery of sand material, coarse and fine sand can be used, suitable for 30 ා - 320 ා sand material.

7. Source manufacturers direct sales, quality assurance, more worry free after-sales.

8. The whole machine is guaranteed for one year. Lifetime maintenance.

9. 13% VAT invoice is available.

Equipment package delivery, package installation, package deb ing, package test sample, package teach customer staff to use. For customers from other provinces and cities, we provide video demonstration, equipment maintenance and other related operation knowledge.

Main parameters of bx1010b sand blasting machine:

Machine dimension: 1400x950x1750mm

Working cabin size: 1000x1000x850mm

Dust removal fan: 220 V, 50 Hz, 550 w

Dust box: automatic recovery filter element dust box, manual dust removal switch

Secondary separator: 1 set

Lighting: 220 V 20W energy saving explosion-proof lamp

Sandblasting head with boron carbide nozzle: 1 set

Sandblasting pipe and air pipe: 1 each

Working window opening: 2

Sandblasting gloves or sleeves: 1 pair

Net board for working cabin: 1 piece

Nozzle support: 1 set

Window glass: 1 piece (430mm * 23mm)

Foot switch: 1

Body material: 2.5 cold rolled steel plate, electrostatic powder spraying on the surface of fuselage, no rusting for a long time

Power requirement: 220 V

Air pressure requirement: 5-7 bar

Machine capacity: 150kg

Net weight: 240kg

Operation of Baixiang manual sandblasting machine:

A: First install and fix the equipment, connect the air source and power supply (the socket is connected to single-phase 220 V, 50 Hz), turn on the power switch, the lighting lamp is on, and the dust removal fan is started.

B: Put the parts to be processed on the worktable and close the door of the working chamber.

C: Insert both hands into the work gloves and hold the workpiece with both hands. The machine has a support for fixing the nozzle. The nozzle should be aligned with the workpiece to be sprayed and adjust the position of the workpiece.

D: Step on the foot switch gently, the workpiece moves relatively under the nozzle, the compressed air passes through the air pipe, and the abrasive will be ejected from the bottom of the storage box to the nozzle according to the set spraying amount. Under the action of the compressed air, the high-speed spray reaches the surface of the workpiece to be processed to complete the sandblasting action.

E: In the process of sand blasting, on the one hand, it is necessary to keep a proper spraying distance and angle between the nozzle and the workpiece in the processing bin of Baixiang sandblasting machine, and on the other hand, the relative movement between the nozzle and the workpiece should be made, so that the surface of the workpiece is evenly sprayed by abrasive.

F: After processing, the foot must be removed from the foot switch. After the nozzle stops spraying abrasive, the working cabin door can be opened and the parts can be taken out.

G: If it is necessary to continue processing parts, it is not necessary to turn off the fan and lighting power supply of the dust removal box.

H: Stop work after work, must turn off the power switch, pull off the power plug, disconnect the air source connector.

I: Clean the dust in the dust box regularly.

Scope of application:

1. Remove and strengthen the surface layer of parts.

2. Cleaning and strengthening of fixtures and materials.

3. Remove the surface layer of parts before electroplating, oxidation and coating.

4. Remove the pollutants on the surface of barrels, pipes, pans, cans and utensils.

5. Removal of tools, molds, pipes, plates and operating parts.

6. Surface cleaning of glass mold, rubber mold, metal casting and extrusion parts.

7. Repair the weld.

8. Remove the surface glaze of the workpiece.

9. Remove the oxide skin on the surface of the workpiece, and remove the color deviation during and after processing (casting, forging).

10. Remove large turbine, engine casting or complex small parts.

11. Remove parts (such as cylinder block, piston and spark plug) during engine maintenance.

12. Clean the surface layer of brush, contactor and wiring to improve the conductivity.

13. Increase the adhesion of workpiece surface.

14. Remove the old paint and impurities on the surface of the workpiece.

Member Information

| Dongguang Huachuang intelligent sandblasting machinery and equipment factory | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13829259081 |

| Contact: | Tony (CEO) |

| Last Online: | 07 Aug, 2020 |

Related Products of this Company

-

Large automatic sand blasting machine

US $38800

-

Environmental protection automatic sand

US $14180

-

Turntable type automatic sand blasting

US $14180

-

Two way conveying au

-

Honeycomb recycling continuous pressure

US $47400

-

Automatic sand blasting machine with wet

US $19950

-

Deburring and chipping Crawler type

US $10520

-

Descaling crawler type automatic sand

US $10520

-

Sandblasting machine for deburring and

US $18500

-

Dust free manual sand blasting machine

US $1280