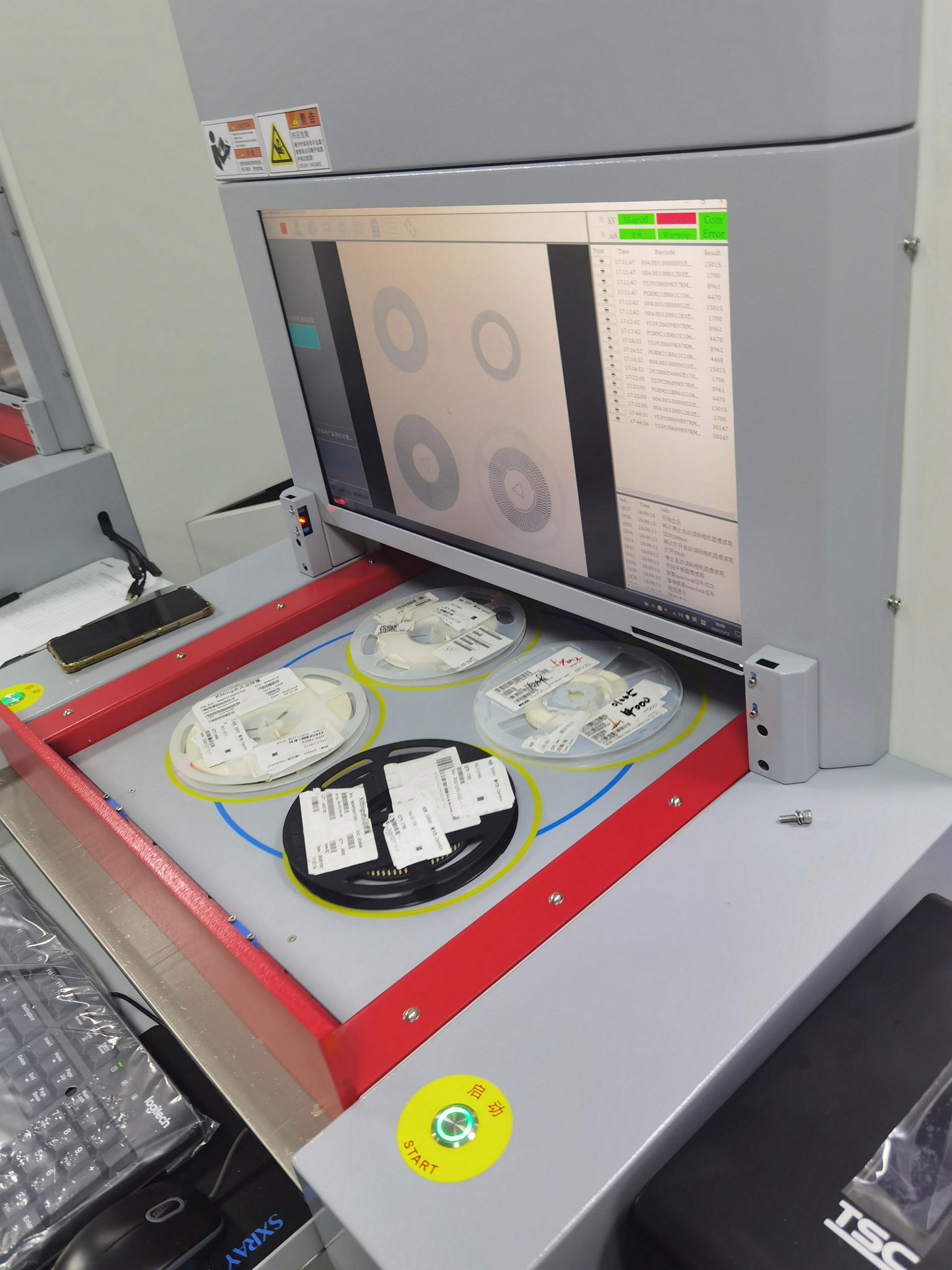

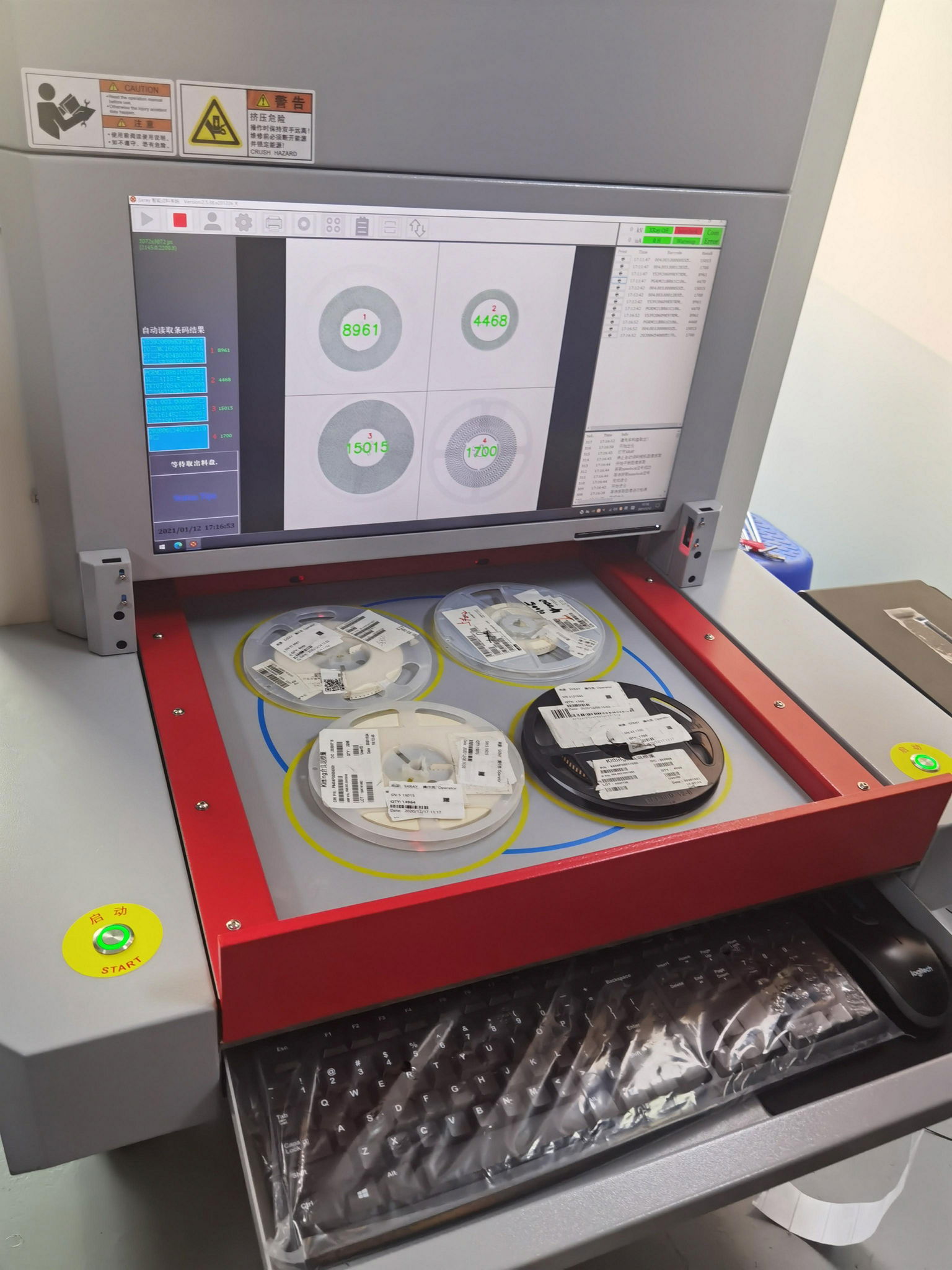

Technical data product model: DS-3000 product name: off-line X-RAY Spotter I. Working principle diagram of the equipment. Device Advantage 1. The x-ray source adopts 80KV closed x-ray tube and is maintenance-free. 2. Shanghai Yirui Iray 17-inch ultra-clean digital flat panel detector, eliminated the scanning detector. 3. Ultra-fast point feed, four 7-inch or one 15-inch trays for about 10 seconds. 4. Can Be ordered up to 17 inches (about 430 mm) in diameter/width, containing moisture-proof bags or JEDEC trays. 5. Proprietary ai deep learning algorithms that accumulate data into a cloud database and share it with all machines. 6. No need to manually scan code, scan code point material at the same time, take out any material tray immediately print the corresponding label. Kill. Compared with the traditional point machine greatly improve the efficiency, accuracy, save manpower, greatly shorten the time of material storage. 8. Support for MES, Erp, WMS system docking, digital management of material warehouse. Software Algorithm Permanent Update. III. Equipment Parameters X ray source, type, closed type, micro focal spot, tube voltage 80kV tube current 700a focal spot size 30m flat panel detector, type, ultra-clear digital flat panel, effective area 430mm * 430mm Pixel size 140m resolution 3072 * 3072 material inventory, maximum size 17 inches (about 430 mm) maximum height 85 mm minimum components, inch 01005(metric 0402) material speed about 10 seconds/sub-point accuracy, greater than 99.95% machine, size 1067 mm long (including label machine) , width 1335 mm, high 1968mm net weight 950kg AC 110-220V 50/60HZ maximum power 800W industrial computer I7-6700 CPU, 8g Ram, 240GB SSD display 24-inch HDMI display, with features, bar code automatic scanning, support Bar Code, two-dimensional code, print labels, take out any material tray immediately print the corresponding label, management system docking MES, Erp, WMS and other security, radiation leakage, no, international standard: Less than 1USV/HR. Rear door security interlock, once open the door, X-ray tube immediately power off, the door can not open when the x-ray. Tray anti-collision protection, tray out, the surrounding steel plate protection, to prevent deformation by impact. Anti-clip hand safety grating, once the hand into the tray movement area will trigger the safety grating, tray immediately stopped, the software at the same time pop-up prompt, when the hand left and soft, software click confirmation, can continue. Emergency Stop Button, located next to the operating position, press the power off immediately. IV. Speed and accuracy, as of now, the time and accuracy of each gauge of material is as follows. With the updating of our algorithm, the database is more and more abundant, the speed of counting material will be faster and faster, and the accuracy will be higher and higher. Tray size, material size (in inch) quantity, accuracy, sentence is too long, please supply a shorter sentence. Artificial intelligence deep learning algorithm, point software using artificial intelligence deep learning algorithm, do not need components and algorithm binding, but use AI to automatically identify components, and automatic application algorithm. The algorithm can learn the component data, such as: 1. Length to width ratio; 2. The angle of each corner of the component; 3. The slope between the inside and outside components; 4. From the inside to the outside component image distortion law and so on. With more and more counting times of components, the result of counting material is more and more accurate. If you encounter similar components, you can easily cope with larger plates. VI. Cloud databases, every device can connect to our cloud database, data and images from the device will be uploaded to the cloud, and the device will automatically download the latest database from the cloud. The engineer also optimizes the algorithm in the background based on the images and data collected by each device and regularly updates it to the database for the customer to use. Over time, equipment point material accuracy will be closer to 100% , the type of components will be more and more wide coverage. When a device encounters a new component whose data is stored in our database, the software can call it directly, with greater efficiency, accuracy, and coverage. VII. Thank you for your attendance.