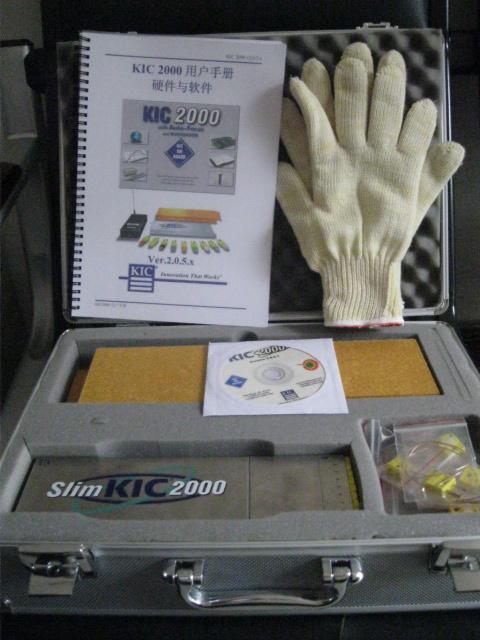

KIC 2000 furnace temperature tester

Thermocouple wire of KIC thermometer

A company specializing in providing SMT Mounter parts and consumables services for electronic manufacturing enterprises. Company agents world-renowned measuring instrument: KIC / TPT Ceyi furnace temperature measurement instrument, in recent years, to provide high-quality sales and training services for many factories, praised by customers and KIC headquarters in the United States Trust, 2010 by the United States KIC KIC headquarters commissioned our Southern China special service department, business inventory of KIC temperature instrument accessories: insulation box, OMEGA thermocouple, KIC thermometer galvanic battery line, buckle, CPU chip, detection and correction maintenance service

With the KIC thermometer galvanic line

SMT SMT accessories and supplies service company for electronic manufacturing enterprises. Company agents world-renowned thermometrics: KIC / TPT Ceyi furnace temperature measurement instrument, in recent years, to provide high-quality sales and training services for many factories, praised by customers and KIC headquarters in the United States Trust, 2010 by the United States KIC KIC headquarters commissioned our Southern China special service department, business inventory of KIC temperature TPT thermometer galvanic line instrument, accessories: insulation box, OMEGA thermocouple, battery buckle, CPU chip, detection and correction maintenance service.

Heat insulation box

OMEGA thermocouple

Data line

Battery button

CPU chip

So easy curve measurement, anyone can do it

The auto processing of complex processes, SlimKIC 2000 it is so easy to make a curve to any operator can quickly complete the process optimization. Simply select the required data from the documents that have collected hundreds of common solder paste specifications, and the software automatically defines the process window. Both the furnace temperature and the thermocouple on the product will automatically use this innovative patented technology.

SlimKIC 2000 simplified the curve measurement, by turning the process into a single data - Process Window Index (PWI), so you can really know how good your curve is. The simplified user interface guides the operator throughout the curve measurement process, minimizing the potential incorrect furnace settings and reducing the error rate.

The Process Window Index

The curve is reduced to a single data

In order to classify the curves accurately, the process window (PWI) is used in KIC software. PWI uses a simple number to show whether the curve conforms to the process window and is objectified and objectified. By comparing and arranging the curves in the optional process window, PWI can help you get the optimal process curve. The smaller the PWI, the more efficient your technology is, the more stable it is. (details refer to PWI data sheet)

Technical specification

Accuracy: + 1.2C

Resolution: Variable 0.3C to 0.1C

Internal operating temperature: 0C to 105C

Thermocouple compatibility: Type K, 9 or 12 channels

Temperature range: -150C to 1050C

Power requirements: Standard 9V alkaline battery

Heat sink: 433.92 MHz (Dual Unit Model only)

Size: see the temperature tolerance table below

Data storage mode: after completing the curve measurement, the data is downloaded to the computer through the download line.

Dual transmission mode: data is transmitted to the computer in real time during measurement. It is also stored in the instrument for high-speed download after measurement.

Temperature tolerance table (the maximum withstand time at the specified temperature, calculated in seconds)

Configuration size (mm)

(Length x Width x Height) 150C 200C 250C 300C 350C 400C

SlimKIC 2000, 9CH unshielded 260.4 x 76.2 x 19.9 8.5 5.5 4.2 3.5

SlimKIC 2000, 12CH unshielded 260.4 x 101.6 x 19.9 8.5 5.5 4.2 3.5

LowRider protective layer 260.4 x 76.2 x 19.9 13.9 8.3 5.5 4.7

Heat insulation sleeves 1/8 (3.2mm), 9CH 323.9 x 86.4 x 26.4 17.6 11 8 6.4

Heat insulation sleeves 1/8 (3.2mm), 12CH 323.9 x 108 x 26.4 17.6 11 8 6.4

LowRider and heat insulation sleeve 1/8? (3.2mm) 323.9 x 86.4 x 26.4 22.6 15.1 10.7 8.7

Heat insulation sleeves 1/4 (6.4mm), 9CH 330.2 x 95.3 x 34.3 24.6 15.5 11.5 9.8

Heat insulation sleeves 1/4 (6.4mm), 12CH 330.2 x 115.6 x 34.3 24.6 15.5 11.5 9.8

LowRider and heat insulation sleeve 1/4? (6.4mm) 330.2 x 95.3 x 34.3 30.7 22.6 16.4 12.2

Long Duration Thermal Shield 381 x 139.7 x 76.2 62.8 42.2 33.1 29.7

Lead free heat shield, 9CH 343.9 x 88.9 x 25.4 18.6 12.7 10.7 9.1 7.9 7.6

Lead free heat shield, 12CH 343.9 x 109.9 x 25.4 18.6 12.7 10.7 9.1 7.9 7.6

Computer configuration

System minimum requirements

400 / 128 Mb Celeron MHz processor, RAM1

1 Gb available storage space (used for product history)

Video 1024 x 768 resolution / 16-bit

1 can use serial port or USB port 2

1 can be used with parallel port or USB port for software key options

Microsoft Windows 2000 or XP3

When KIC2000 software and furnace software are running on a computer, and / or with other KIC software options, faster CPU and larger RAM may be required.

You may need a USB adapter to connect SlimKIC 2000 to curve measurement.

If you have problems in the operating system beyond the problems listed above, please connect to the KIC.