| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

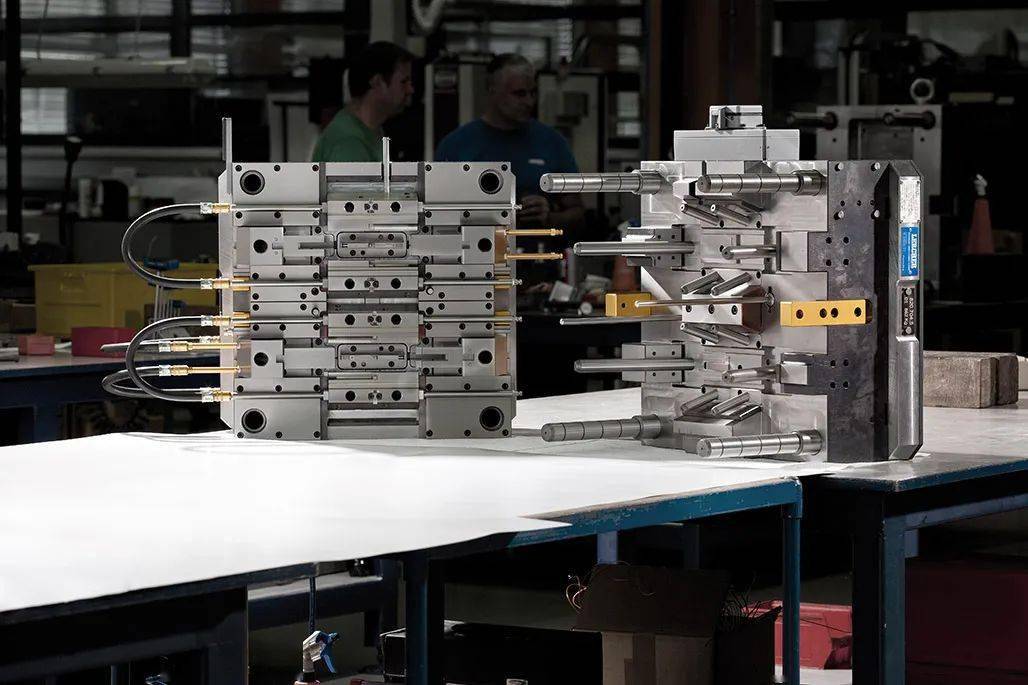

| Category: | Industrial Supplies / Machine Hardware / Mold |

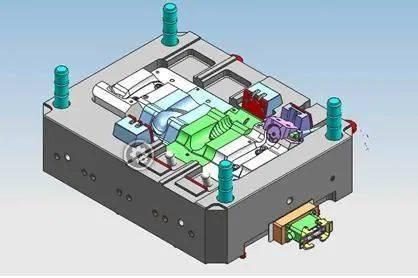

| Label: | Hardware mould , Plastic mold , Die casting mold |

| Price: |

-

|

| Min. Order: | - |

Product Description

A set of reliable plastic mold design is mainly reflected in the quality of the molded plastic products (appearance quality and dimensional stability), convenient, rapid, and concise processing and manufacturing, which saves money and manpower, and leaves room for correction and improvement. It is safe, stable, easy to maintain, has a short molding cycle and a long service life during injection molding, and has reasonable mold manufacturing technology.

01. The main process of factory mold design

Customers provide product drawings → analyze products → confirm plastic varieties → confirm mold material → transfer engineering drawings → multiply and shrink to make mirrors → improve assembly drawings → order mold blanks → order mold core materials → draft → 3D parting → determine runners /Gating method→Refer to the ranking drawing for structural design→dismantle inserts→correct 3D→engineering drawing (mold core/insert/mold blank/parts)→make BOM table→proof and review.

02. Several aspects that should be paid attention to in design

1) When we start the mold design, we should pay more attention to several options, weigh the advantages and disadvantages of each option, and choose one of them, and take the T mold seriously. Because of the time understanding, it was believed that a reasonable design at that time would definitely have possible improvements through production and use practices.

2) After handing over the design plan, communicate with the factory more to understand the processing process and the situation in manufacturing use. Each set of molds should have a fixed analysis experience, sum up the process of gains and losses, in order to continuously improve the level of mold design.

3) When designing, refer to similar drawings designed in the past to learn from its experience and lessons.

4) The mold design department should be a whole, and each design member cannot work independently, especially in terms of mold design summary conclusions, it must have a unique style.

03. Mould design basis

The main basis is the product drawings and samples provided to us by customers. Designers must carefully analyze and digest the products and samples. At the same time, they must check all items one by one during the design process.

1. Dimensional accuracy related to the correctness of dimensions

1) Plastic products with high appearance requirements and low dimensional accuracy requirements, such as toys, etc., except for the conversion of specific dimensions, as long as the other dimensions are in good agreement.

2) Products with strict requirements on appearance and size

Whether the draft angle is reasonable.

Product wall thickness and uniformity.

Type of plastic. (Selection of mold steel and determination of shrinkage rate)

Surface requirements.

Product color.

In general, color has no direct influence on mold design. When the product wall is thick and the appearance is larger, the color is easy to be uneven; and the darker the color, the more obvious the product defects are exposed.

2. Is there any post-processing after the product is formed?

If there are products with surface electroplating and one mold has multiple cavities, you must consider setting up auxiliary runners to connect the products together, and then separate them after the electroplating process is completed.

3. Batch of products

The batch of products is an important basis for mold design, and the customer must provide a range to determine the number of mold cavities, size, mold material selection and life.

4. Injection molding machine specifications

5. Customer's other requirements

The designer must carefully consider and check to meet the compatibility requirements.

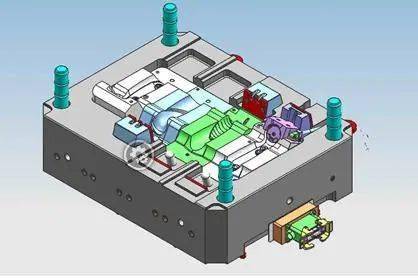

04. General process of mold design

1) Analyze and digest products and samples.

2) It should be understood whether the customer has requested the specifications of the injection machine to determine the size of the mold.

3) Determine and rank the number of cavities.

4) The parting surface is determined.

5) If there is a row position and an oblique square structure, it should be understood first.

6) Design of pouring system

7) Confirmation of mosaic structure.

8) Design of ejection and reset system.

9) Cooling and heating system design.

10) Guiding and positioning device.

11) Determine the mold base and select standard parts.

12) Selection of mold steel.

13) Complete the structure drawing, mold blank drawing, and cutting material.

14) Finally, print out the drawing, check it, and submit it to the mold design team leader and supervisor.

05、Trial and repair

Although the mold design is carried out under the expected process conditions when the molding material and molding equipment are selected, people’s understanding is often imperfect. Therefore, after the mold processing is completed, a trial mold test must be carried out to see the molded part. How is the quality. After discovering that it is always the case, repair the model to eliminate errors.

There are many types of undesirable phenomena in plastic parts, and the reasons are also very complicated. There are reasons for molds and process conditions, and the two are often intertwined. Before repairing the mold, according to the actual situation of the undesirable phenomenon of the plastic part, a detailed analysis and research should be carried out, and the remedy method should be proposed after finding the cause of the defect of the plastic part. Because the molding conditions are easy to change, the general approach is to change the molding conditions first, and only consider repairing the mold when the changing molding conditions cannot solve the problem.

Repair molds should be more cautious, and do not act rashly if you are not very sure. The reason is that once the mold conditions are changed, it cannot be remodeled and restored to the original state.

06. Organize data and archive

After the mold is tested, if it is not used temporarily, it should completely wipe off the mold release residue, dust, oil, etc., apply butter or other anti-rust oil or anti-rust agent, and send it to the storage place for storage.

From the beginning of the design of the mold until the mold is successfully processed and passed the inspection, the technical data generated during this period, such as the task book, the part drawing, the technical manual, the mold assembly drawing, the mold part drawing, the base drawing, the mold design manual, and the inspection record Forms, trial and repair records, etc., are systematically sorted, bound, numbered and archived in accordance with regulations. This seems very troublesome, but it is very useful for repairing the mold in the future and designing a new mold.

Member Information

| Huizhou Shunqiang Electronics Co., Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13715334662 |

| Contact: | Kennethchui (Engineer) |

| Last Online: | 28 Oct, 2024 |

Related Products of this Company

-

Automobile air conditioner shell mould

-

3 sets of classic mold structure

-

12 sets of mold structure diagram

-

How to improve the structure of

-

Technical knowledge of plastic molds

-

9 design cores for stamping die!

-

Mold design gate position inlet

-

Automobile air conditioner shell mould

-

Slider out of the slider

-

Stamping is based on the press and die