| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

| Label: | Hardware mould , Plastic mold , Die casting mold |

| Price: |

-

|

| Min. Order: | - |

Product Description

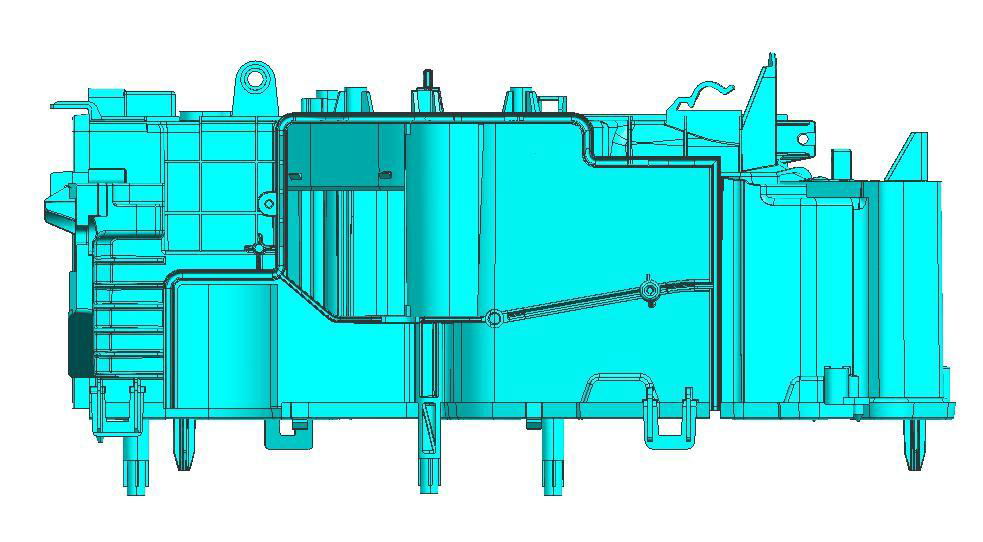

Among automobile structural parts, air-conditioning shells are representative of more complex products. Today we will take the air-conditioning shell as an example to analyze the design of its mold structure, which is of practical reference value for everyone.

01

product analysis

The car air conditioner shell is the core component of the car air conditioner, and the product material is PP-TD20. Product design needs to consider multiple functional requirements for assembly, drainage, and wind, so its structure is relatively complicated.

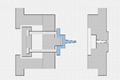

At the beginning of mold design, how to divide the front and rear molds is an important issue. According to conventional thinking, naturally the side with more bones and more columns is in the back mold, and the side with smooth and less bones is in the front mold. Because this product is a structural part, the appearance requirements are not high, so the side with more bones is divided into the front mold, the smooth surface and the side with less bones are divided into the back mold, and the front and back molds are treated harshly.

02

Product glue

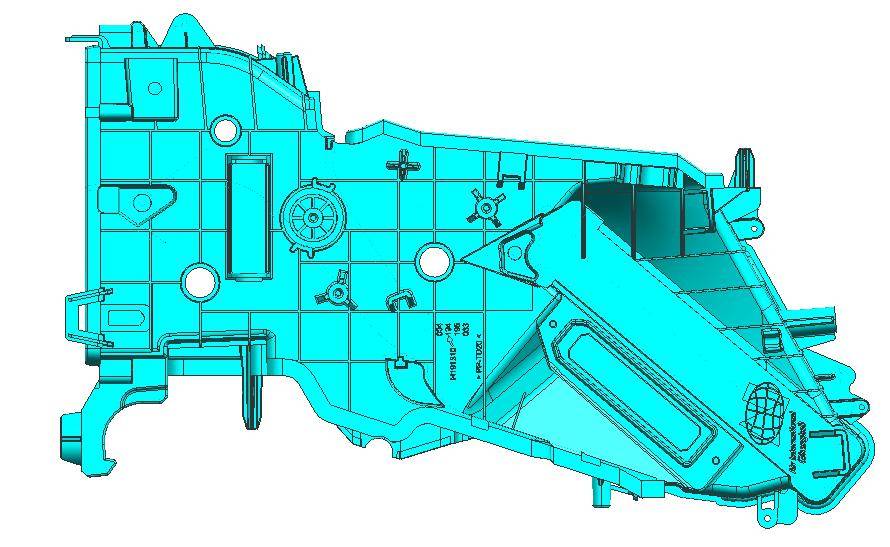

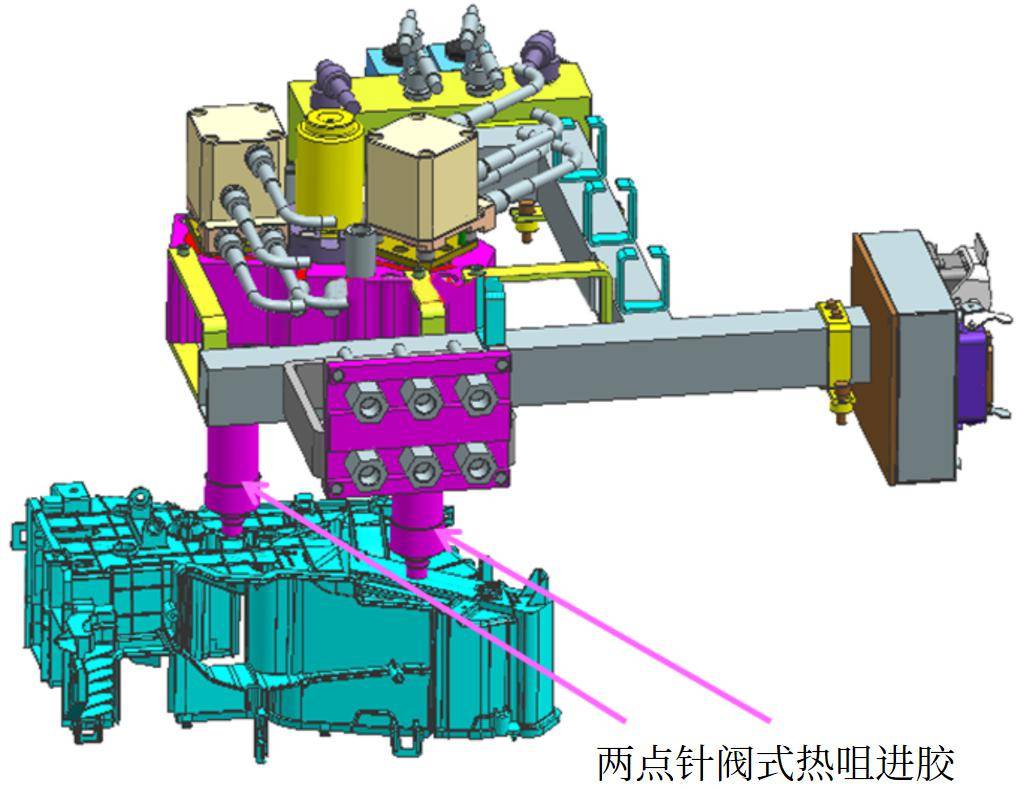

The product uses a two-point needle valve hot nozzle to feed the glue and directly point it on the surface of the product, as shown in the figure below.

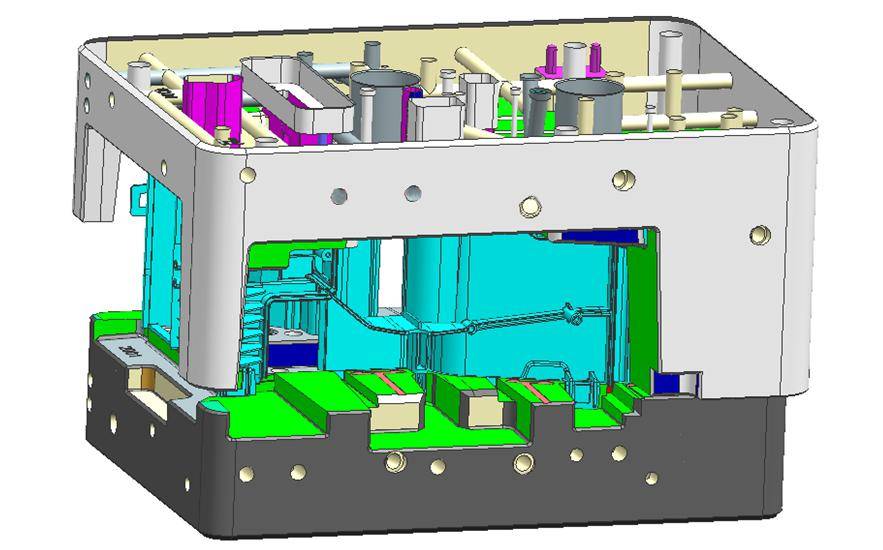

The front and rear molds are inlaid harshly

03

Mould structure

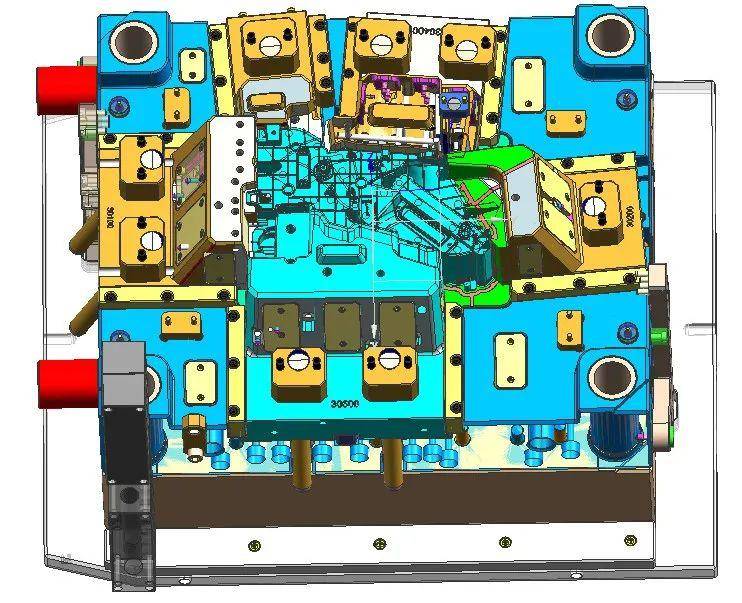

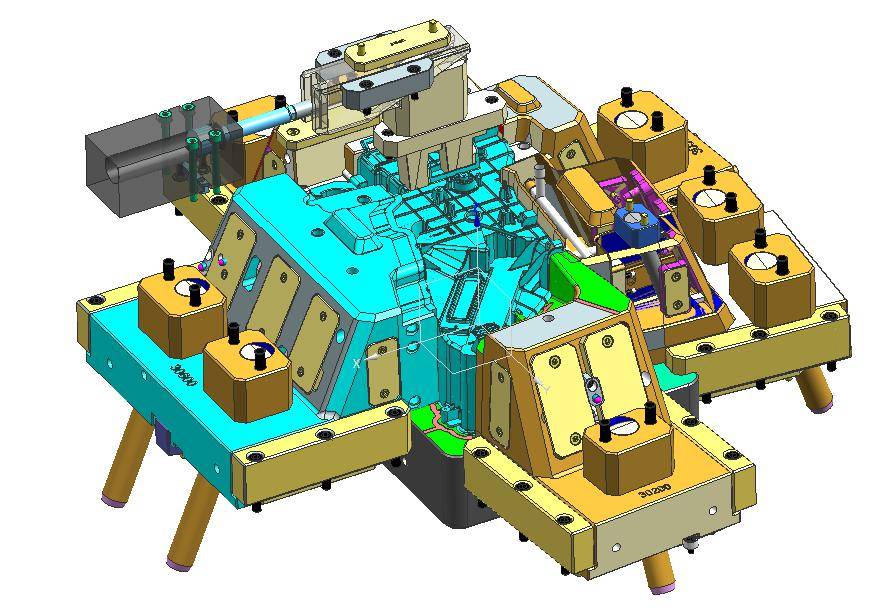

Mould structure 1 (front mould row position)

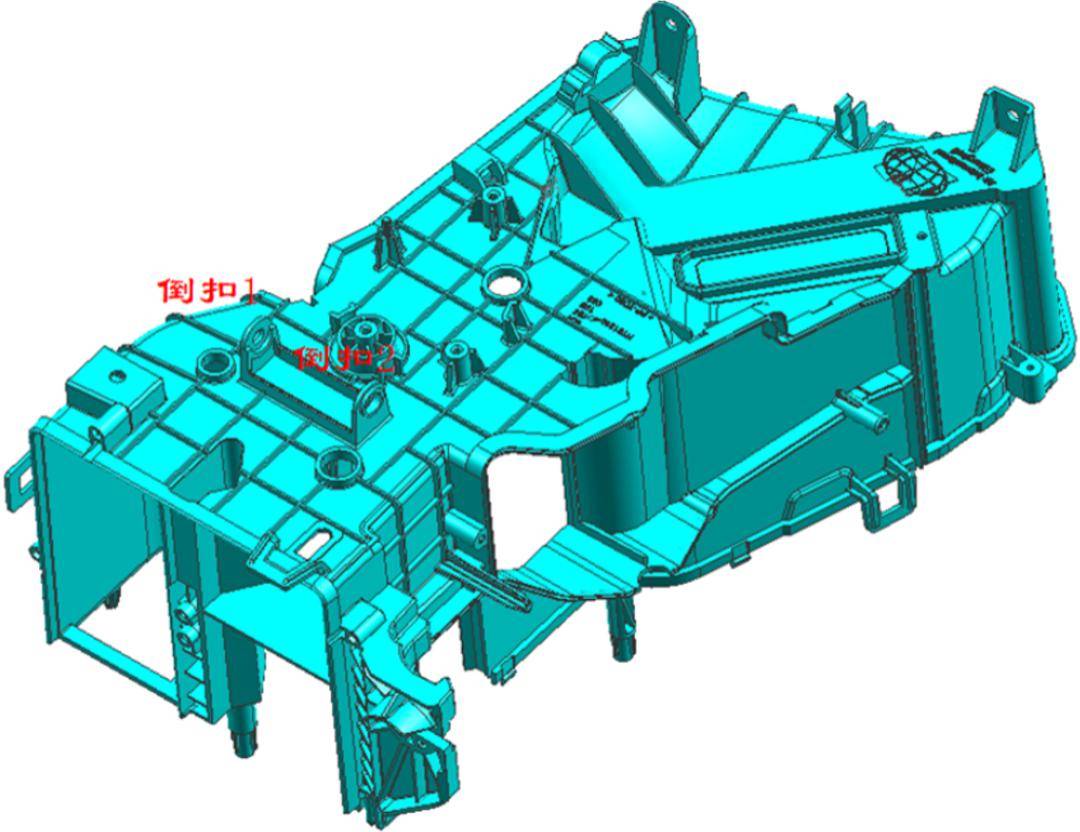

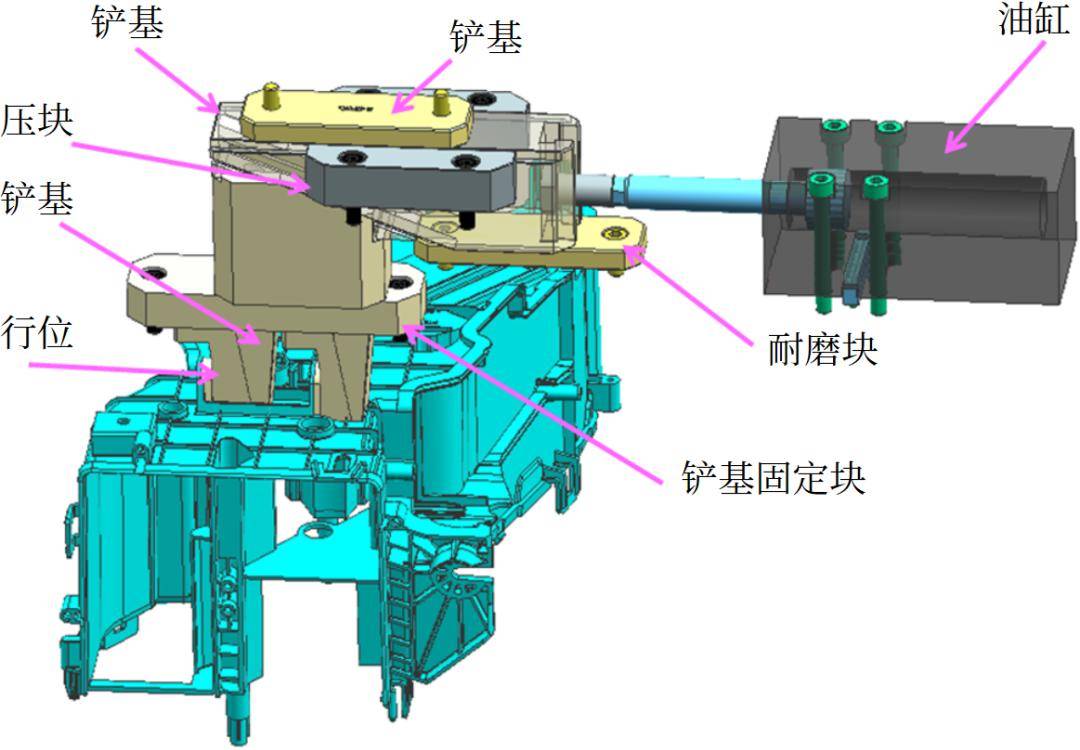

The undercut 1 and undercut 2 are in the front mold. According to the general thinking, the front mold inclined top structure or the elastic plate core can be used. This mold uses a cylinder to convert the core, one cylinder controls two positions, and uses the shovel base to seal the glue. .

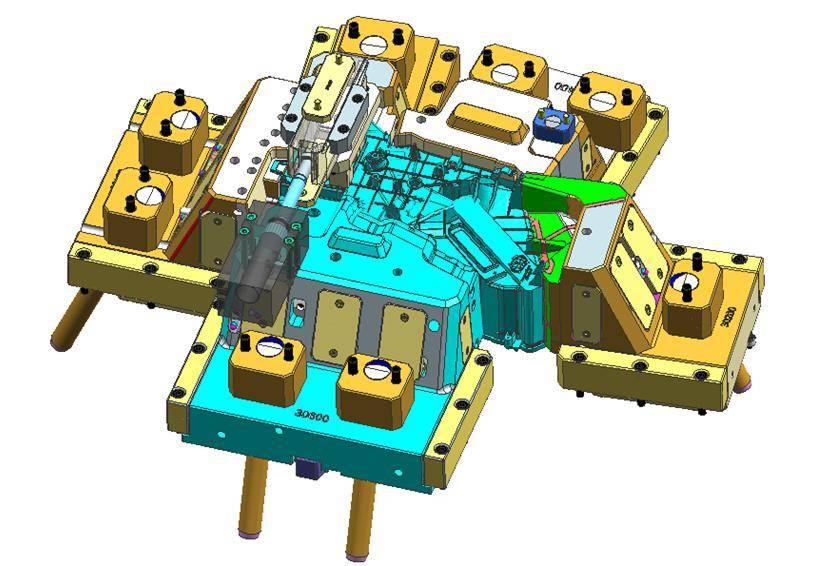

Mold structure 2 (rear mold row position 1)

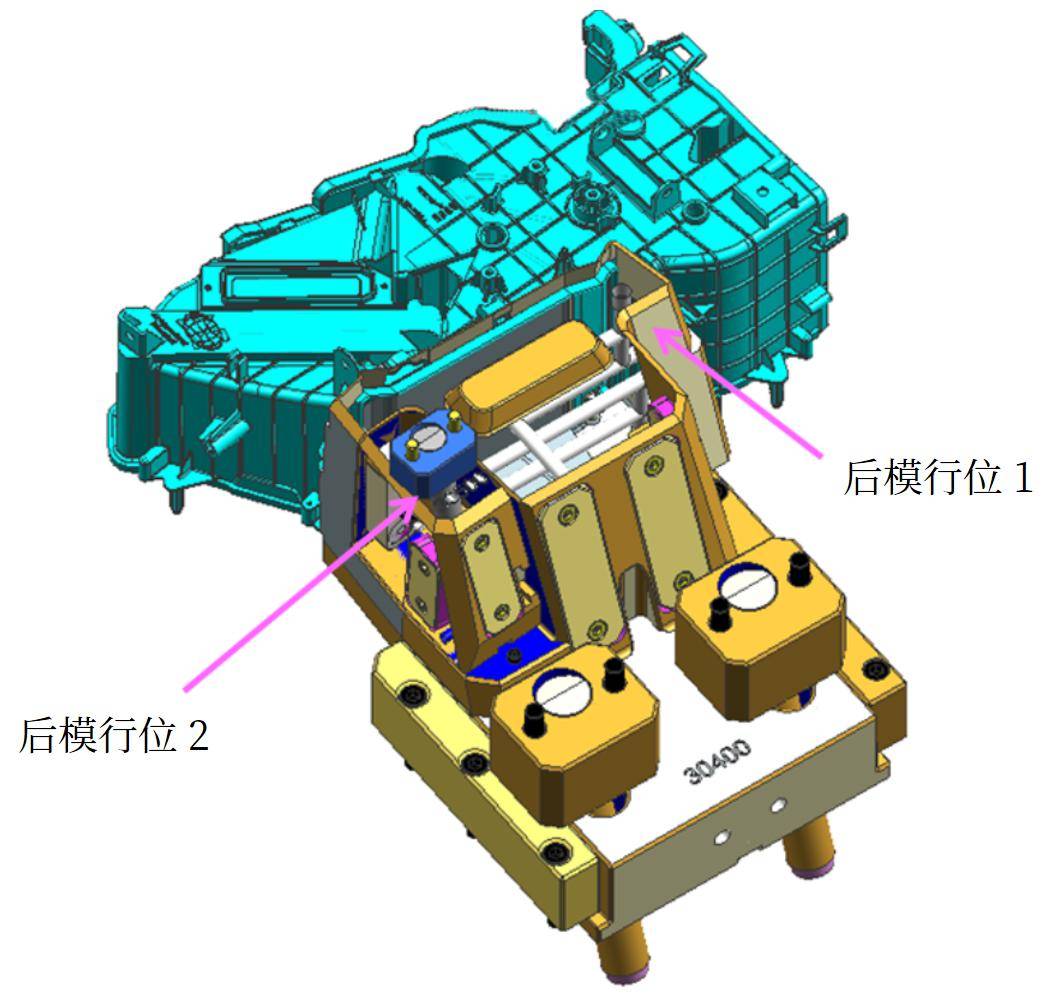

Rear mold row position 1 and row position 2 are the structure of the row position. Because of the limited space, the row position 2 cannot be used as a row position block. The design adopts T groove as a guide. This mechanism is suitable for occasions with a small row position. .

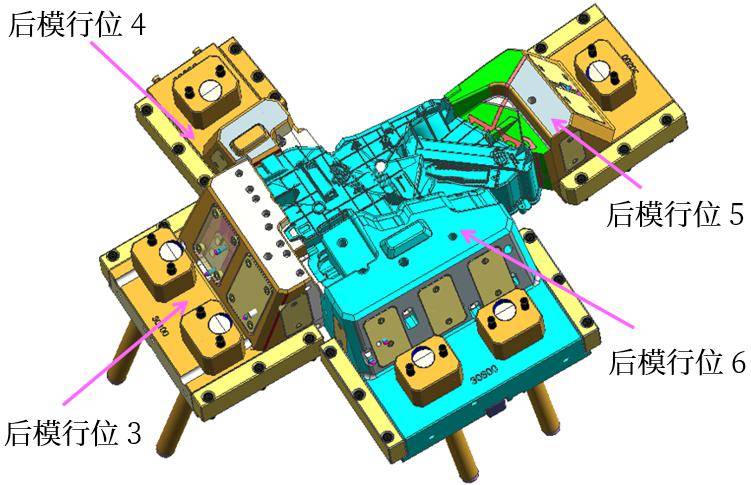

Mold structure (rear mold row position 3/4/5/6)

The rear mold row position 3/4/5/6 is a conventional row position structure, and part of the row position adopts a spring needle device to prevent the product from sticking to the row position.

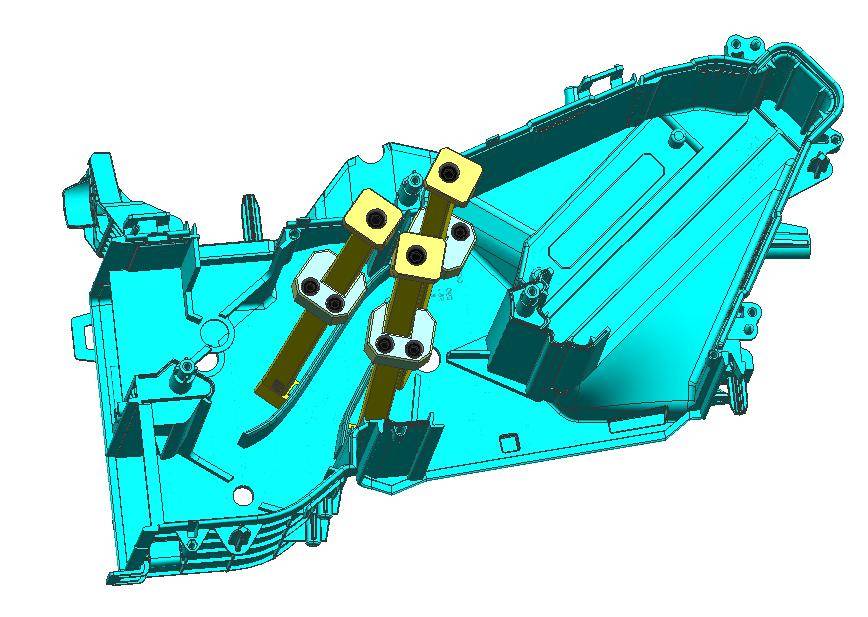

There are three undercuts on the side of the posterior mold bone, with three square inclined tops.

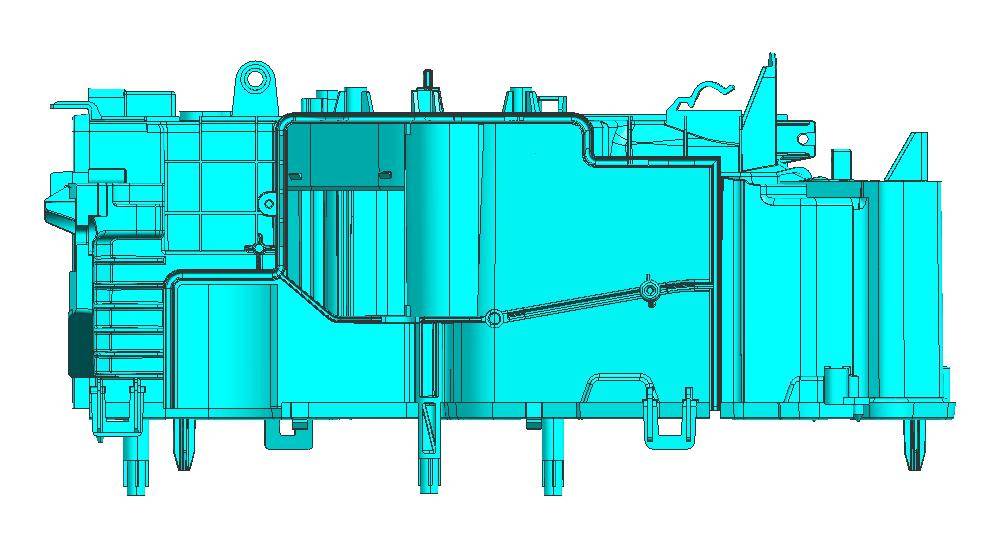

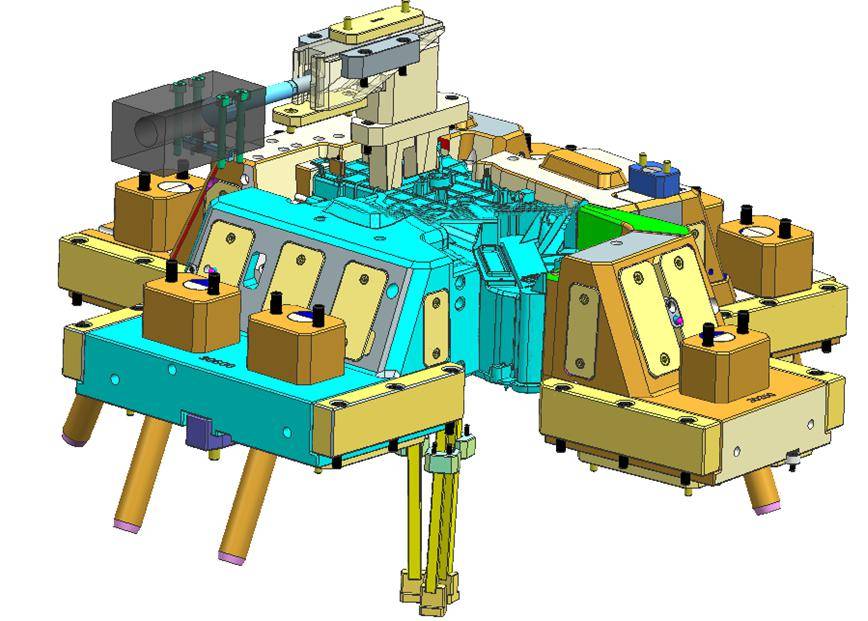

Overall rear mold

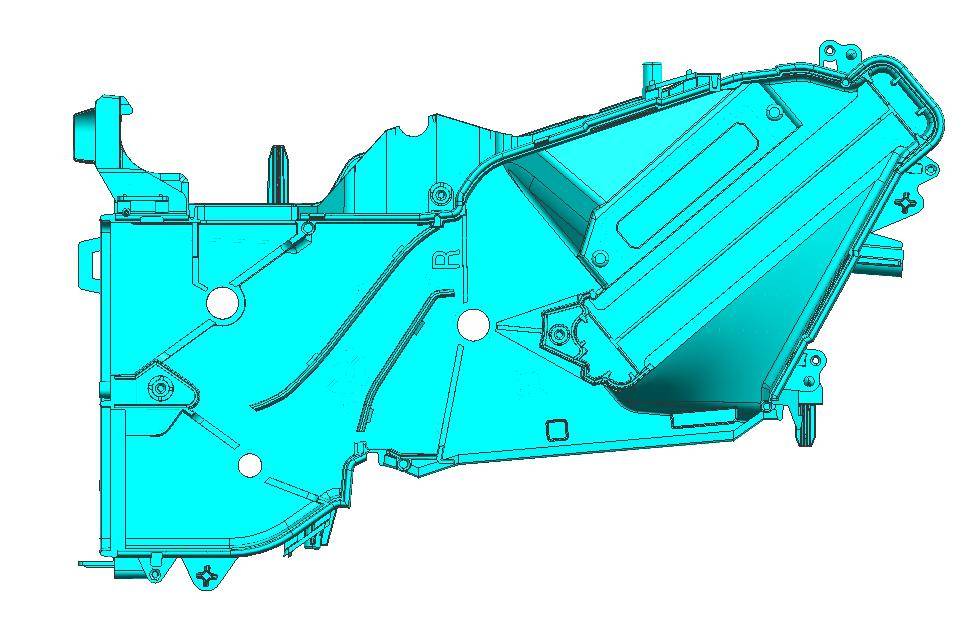

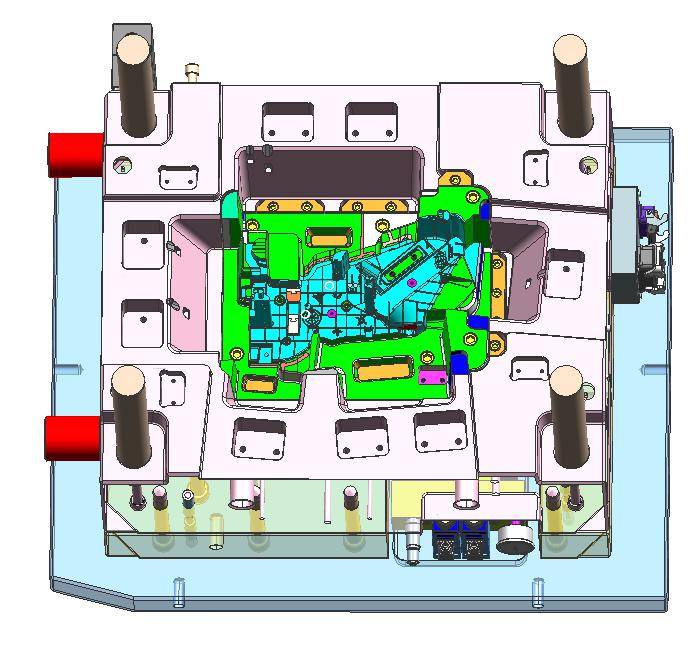

Overall front mold

Member Information

| Huizhou Shunqiang Electronics Co., Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13715334662 |

| Contact: | Kennethchui (Engineer) |

| Last Online: | 07 Dec, 2024 |

Related Products of this Company

-

How to improve the structure of

-

Stamping is based on the press and die

-

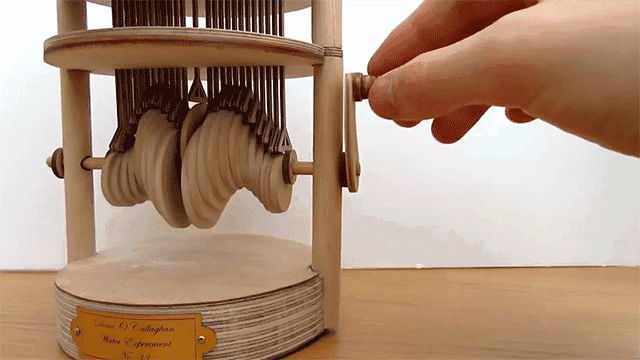

Dynamic diagram of how to demold a

-

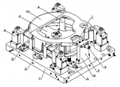

12 sets of mold structure diagram

-

A set of mold design ideas and processes

-

Slider out of the slider

-

50 dynamic diagrams of mold structure

-

Mold design gate position inlet

-

New insert type spring clamp chuck

-

Mold vacuum heat treatment technical