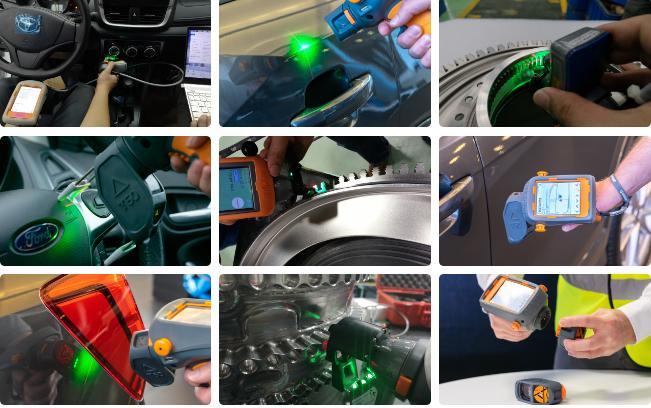

THIRD DIMENSION GAPGUN PRO laser gap measuring instrument Product name: GapGun PRO laser rangefinder/contour quantifier/laser gap gun Product model: GapGun PRO Brand: THIRD DIMENSION Instrument type: Optical measurement Application fields: Railway/Shipbuilding/Transportation Petroleum /Chemical aerospace automobiles and parts steel/metal product introduction: GapGun PRO with excellent measurement results and contour quantification capabilities Detailed introduction: The world's first handheld laser measuring instrument, GapGunPRO's built-in lithium battery can operate offline without external power supply. At the same time, maintain high-speed contour analysis functions: choose to connect and work synchronously with SPC3d software, use customized simulation tools, and instantly realize multiple functions such as scanning, reading analysis, and data report generation for a variety of complex contours.The standard equipped shock-proof probe protective cover provides sufficient protection for the equipment in long-term and harsh working environments.GapGun PRO touch screen operation interface, user-friendly design, clarity, and feedback rate are comparable to today's smartphones.Through SPC3d connection, it can be accurately guided to the measurement position, control the measurement method and angle, and compare the design values in real time or make pass-stop judgments and out-of-tolerance prompts.The software provides customization of data export formats.There are optional replacement probe models: 7mm, 15mm, 40mm, and 80mm.Each probe is certified based on six-sigma and VDA5 and can be rotated 180°.Developed in cooperation with Rolls Royce, it is now used as standardized testing equipment for Airbus, Lockheed Martin, etc.The usage rate in the global aviation and automobile manufacturing fields is as high as 80%, and it is also the laser inspection equipment used by the market-leading smartphone and laptop manufacturers.Third Dimension GapGun Laser Gap Gun (Specialized for Aerospace) Product Features: The aerospace industry has high requirements for assembly geometry measurement.In addition to the large number of parts and complex contours, the working safety performance of the components is also very important.Therefore, the aerospace industry uses the most advanced measuring equipment on the market.GapGun GapGun is the first in assembly dimensional measurement technology in today's aerospace industry.Faced with the measurement difficulties in the aerospace industry, the measurement technology of GapGun can effectively solve them.Product Application GapGun wireless gap gun is widely used in the world's civil and international aerospace industries, effectively solving the measurement needs of each production stage.The following are some applications of GapGun in the aerospace industry: Gap dimensions of major components such as the fuselage, apertures, and wings Internal measurement areas such as rib feet and wing boxes Protruding and parallel apertures of rivets and Countersunk hole size measurement, contour scratch depth and surface damage of turbine blades, plane difference and angle chamfer and radius measurement of assembled airfoil · Third Dimension GapGun laser gap gun (special application) Product Features: GAPGUN’s application range is not limited to Car and aircraft measurements.With GAPGUN's lightweight structure, hardware compatibility, and software functions, GAPGUN can meet the measurement requirements of almost all walks of life.Product application: Measuring the brake pad gap and surface loss of engineering machinery such as cranes. GAPGUN. Some other application ranges include measuring the gap between rollers and large household appliances. Measuring the degree of damage after an explosion. Guaranteed to be 100% imported.