| Model: | ZSVI2615 |

|---|---|

| Brand: | zsvi |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Solders |

| Label: | liquid filter bags , liquid filte machine , ultrasonic welding |

| Price: |

¥14000

/ pc

|

| Min. Order: | 1 pc |

Product Description

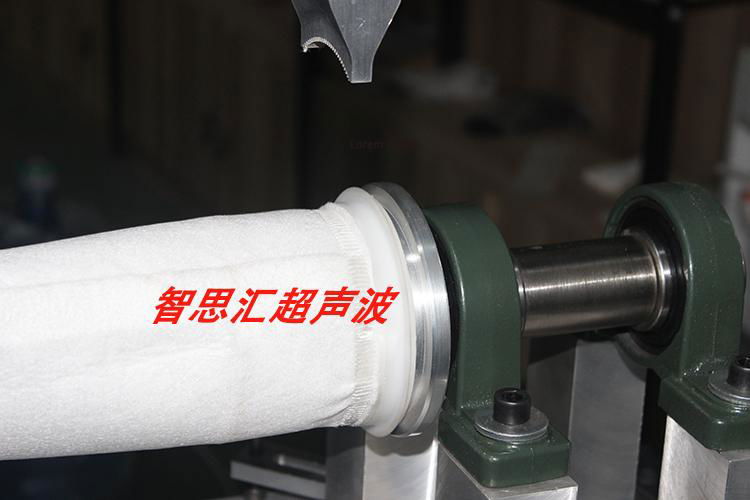

Welding of liquid filter bag mouth:

Ultrasonic welding is adopted to weld the PP filter cloth and PP plastic ring together (PE cloth and PE plastic ring). The circular arc of the standard plastic ring with a diameter of 180 needs to be welded into a whole circle six times. For liquid filter bags of different models and sizes, we make different molds to realize multi-purpose of one machine and save investment cost.

Ultrasonic welding process:

1. Working power supply: AC 220V ± 10V / 50h Z

2. Apparent power of transducer: 2600w

3. Ultrasonic frequency: 15Hz

4. Welding time: 0.1-4 seconds

5. Pressure holding time: 0.05-3s

6. Effective stroke of welding head: 75mm

7. Pneumatic

8. Desktop 590 × one hundred and five × 980 (can be raised to 1380)

10. Net weight: 70-85kg

11. Specification: zsvi-2615

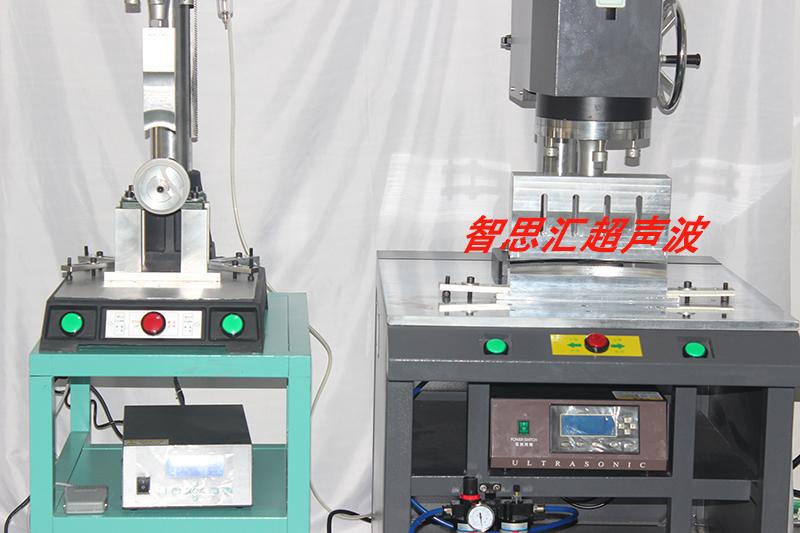

Sealing welding at the tail of liquid filter bag: the tail can be welded into "V" shape or "-" shape. Only one 4200W ultrasonic welding machine is required for one-time sealing welding. Finally, trim the excess material and close the wool floc.

Technical parameters:

Operating frequency: 15K

Working power: 4200W

Welding stroke: 100mm

Working voltage: 220V ± 10%

Air source: 0.2-0.7mpa

Lifting mode: hand operated

Horizontal adjustment plate: l650w650

Working base: luxury desk

Body size: L650 × W750 × H1880

Net weight of fuselage: ≤ 150kg

Language system: Chinese / English

Machine introduction:

Ultrasonic welding is to convert 50 / 60Hz current into 15-40khz electric energy by ultrasonic power generator

The energy exchange system is then converted into high-frequency mechanical vibration, and then transmitted to the welding head through amplitude amplification by the horn. The ultrasonic welding head transmits the received vibration energy to the joint of the plastic workpiece to be welded. Through instantaneous ultra-high frequency friction on the surface of the plastic workpiece, the workpiece interface melts rapidly, and the molecules on the surfaces of the two interfaces recombine and fuse, So as to achieve seamless welding of weldment interface without damaging the product appearance

Equipment Description:

High performance anti-interference microprocessor is adopted to realize electronic control. All parameters of welding control are managed by microcomputer. The intelligent frequency control system avoids the inconvenience of manual frequency modulation, tracks the best resonance point in real time, monitors the temperature change of welding head and transducer, adjusts the adaptation frequency, and maintains the stable output of machine power, so as to ensure the welding effect.

The bottom, side and collar of the hot-melt filter bag are also welded with full hot-melt ultrasonic to ensure that the welding at each point is the most firm and consistent, to ensure that the liquid filter bag is not affected by other production auxiliary materials, and to ensure the consistency of the material of each liquid filter bag. It can effectively break the side leakage problems and fiber falling off problems caused by the uneven pinholes and materials of the traditional suture liquid filter bag, which are all solved by the full hot-melt welded liquid filter bag.

Member Information

| wuxi zsvi welding technology limted company | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 15006191865 |

| Contact: | Lisa (seller manager) |

| Last Online: | 14 Dec, 2021 |

Related Products of this Company

-

china 4200w ultrasonic welding machine

US $6000

-

Digital automatic plastic ultrasonic

US $6000

-

plastic filder folder ultrasonic making

US $1750

-

Nylon woven bag wireless ultrasonic

US $750

-

liquid filter bag top and bottom

US $4800

-

Face Masks Anti-Fog with face shield

US $1850

-

ultrasonic welding machine

US $1700

-

Ultrasonic Welding Machine for Car and

US $2000

-

pp hollow plate corrugated sheet box

US $2300

-

Ultrasonic generator and transducer

US $1200